I only need to do some smaller stuff,and have plenty of material to learn with.

I came across this machine pictured below for cheap and picked it up.

I plan to purchase a better machine later,but for beginning and experience I want something that I'm not too worried about damaging.

First question,what the heck is it?

A friend of mine that has worked in a machine shop said it's either a bridgeport or copy of one.

There are no identifying marks anywhere I can see,though I have yet to disassemble anything.

Any help with that would be nice.

Also,the mill does not have a head on it. When I pop the top where the belt drive is there is a rod (removable) with the bottom end threaded that goes through a hole straight down between the pulleys.

I assume the thread at the end is for the milling head,but embarassed to say i'm not even sure what I'm looking for.

Is it an attachment similar to a drill? or more like a chuck with a collet in it?

Pics of similar machines would help,just can't seem to find the right wildcard search words.

I would like to get started using the mill,right now it's just sitting on the table.

I am about to mount it and get it and my drill press better setup to use next to my metal fab table.

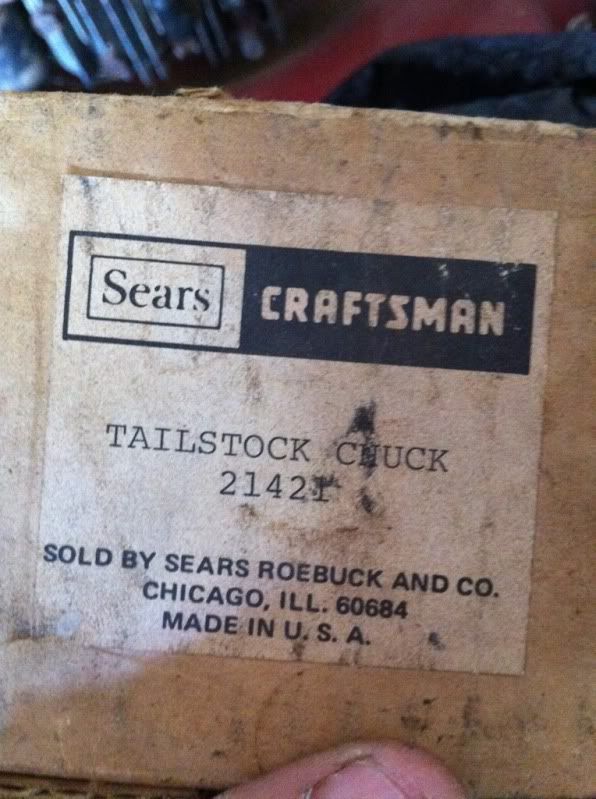

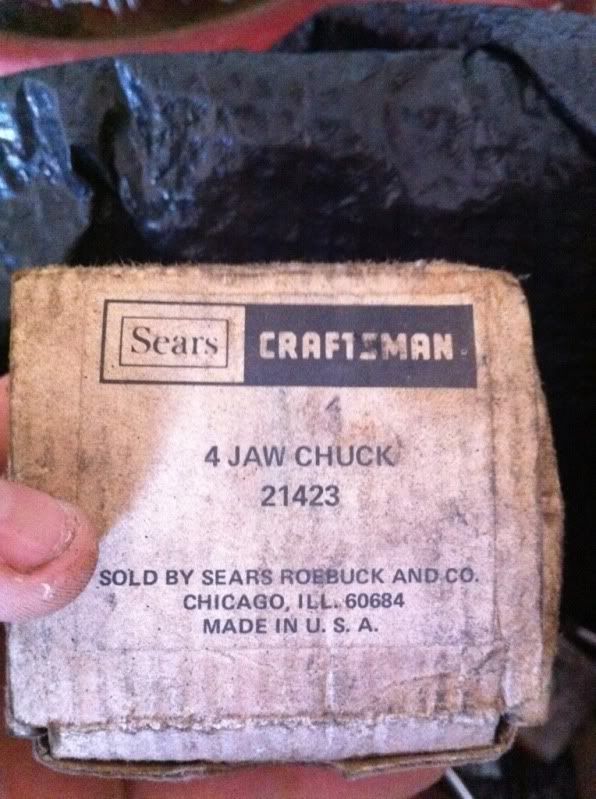

I am enclosing pics of a couple NOS/NIB craftsman parts that came with it.

The guy I got it from only used the lathe a few times,then found a bridegport lathe so didn't need this.

He never had a need for the mill and gave me all the parts the old man he bought it from gave him.

I don't beleive they go with it,but might even be the part i'm needing for all I know.

I hate asking dumb questions,but not really anyone to ask around here that would know.

Thanks for even looking and giving the smallest bit of advice.