help ignorant novice on basic approach to making this part

-

jimbarstow

- Posts: 2

- Joined: Wed Nov 26, 2014 11:43 am

help ignorant novice on basic approach to making this part

I've taken a beginner machinist course at a local school and am now the owner of a sherline

lathe and mill (including the rotary table).

As one of the first useful things I want to make is a large compass divider head. (The size

is still manageable by the sherline.) You can buy big dividers but they are quite expensive and

this seemed like a fun first project.

I know how to mill given aspects of the part but I'm not sure how to put it all together into

one coherent approach. For example, I know how to mill the inside and outside curves of the divider

head using a rotary table but which to do first?

Any general advice on how to start would be appreciated. In fact, any advice at all would be appreciated.

I'm a very accomplished, self-taught woodworker and I feel like I did 30 years ago facing a piece of

wood: where do I start?

I've included pictures of the compass divider I did in sketchup. They aren't cad-level quality but should give you

an idea of what I'm after.

lathe and mill (including the rotary table).

As one of the first useful things I want to make is a large compass divider head. (The size

is still manageable by the sherline.) You can buy big dividers but they are quite expensive and

this seemed like a fun first project.

I know how to mill given aspects of the part but I'm not sure how to put it all together into

one coherent approach. For example, I know how to mill the inside and outside curves of the divider

head using a rotary table but which to do first?

Any general advice on how to start would be appreciated. In fact, any advice at all would be appreciated.

I'm a very accomplished, self-taught woodworker and I feel like I did 30 years ago facing a piece of

wood: where do I start?

I've included pictures of the compass divider I did in sketchup. They aren't cad-level quality but should give you

an idea of what I'm after.

Re: help ignorant novice on basic approach to making this pa

I would do the more difficult work on the rotary table first as this is where it is easiest to screw up. The straight milling cuts are easy, so do that last. For the quadrant, I would mill the slot first on the RT using an end mill the width of the slot. Then mill the outside radius's using progressively deeper cuts. You don't want to distort the quadrant from excessive cuts. I'm sure others would do it differently, but that would be my approach.

Mr.Ron from South Mississippi

- tornitore45

- Posts: 2077

- Joined: Tue Apr 18, 2006 12:24 am

- Location: USA Texas, Austin

Re: help ignorant novice on basic approach to making this pa

When machining the quadrant as Mr Ron said, be careful in the last cut of the exterior.

Clamp or screw down on a flat piece of wood the blank plate and secure the material that will be the finished quadrant by placing several screws in the internal slot.

When the last cut makes two pieces out of one blank you do not want the free quadrant to move catch the end mill, break it and fling the all bent quadrant into an unreachable place of the shop.

In general metalworking requires a bit more planning on the sequence of operations.

There is no substitute for hands on experience, one example is the direction of the forces the tool place on the part and the holding device. You can mill a thin part hitting in across the thickness an the part will easily vibrate or bend or you came in tangentially with the tool and direct the force predominantly parallel with the length (orthogonal to the thickness) that prevent flapping and bending, even so if you are feeding heavy it may suck the part into the cutter on conventional milling, but will flex the part safely by climbing.

I cited this as an example of the thing you learn by doing (and failing), since there is no way to educate yourself before you come to each specific situations.

You will notice that many suggestion come with a humorous "do not ask how I know" a sure indication of learning by failure.

Do not mean to dampen your enthusiasm, but failing is part of learning.

Clamp or screw down on a flat piece of wood the blank plate and secure the material that will be the finished quadrant by placing several screws in the internal slot.

When the last cut makes two pieces out of one blank you do not want the free quadrant to move catch the end mill, break it and fling the all bent quadrant into an unreachable place of the shop.

In general metalworking requires a bit more planning on the sequence of operations.

There is no substitute for hands on experience, one example is the direction of the forces the tool place on the part and the holding device. You can mill a thin part hitting in across the thickness an the part will easily vibrate or bend or you came in tangentially with the tool and direct the force predominantly parallel with the length (orthogonal to the thickness) that prevent flapping and bending, even so if you are feeding heavy it may suck the part into the cutter on conventional milling, but will flex the part safely by climbing.

I cited this as an example of the thing you learn by doing (and failing), since there is no way to educate yourself before you come to each specific situations.

You will notice that many suggestion come with a humorous "do not ask how I know" a sure indication of learning by failure.

Do not mean to dampen your enthusiasm, but failing is part of learning.

Mauro Gaetano

in Austin TX

in Austin TX

Re: help ignorant novice on basic approach to making this pa

If you're doing it that way to learn or prove you can, then fine.

However, just because you have a mill doesn't mean that everything must be made by milling. As a novice, you will need to learn when to cut from the solid and when to fabricate.

I would make the divider arms from flat stock with slices of round stock silver soldered to the (preformed by milling) ends of the arms.

A further simplification would be to abandon that quadrant design and use a suitably sized steel rod bent into an arc. Anchor it with a fitting to one arm and have it pass through a hole in a fitting on the other arm. A setscrew in the latter fitting would lock the rod to hold the measurement.

However, just because you have a mill doesn't mean that everything must be made by milling. As a novice, you will need to learn when to cut from the solid and when to fabricate.

I would make the divider arms from flat stock with slices of round stock silver soldered to the (preformed by milling) ends of the arms.

A further simplification would be to abandon that quadrant design and use a suitably sized steel rod bent into an arc. Anchor it with a fitting to one arm and have it pass through a hole in a fitting on the other arm. A setscrew in the latter fitting would lock the rod to hold the measurement.

Regards, Marv

Home Shop Freeware

http://www.myvirtualnetwork.com/mklotz

Home Shop Freeware

http://www.myvirtualnetwork.com/mklotz

- tornitore45

- Posts: 2077

- Joined: Tue Apr 18, 2006 12:24 am

- Location: USA Texas, Austin

Re: help ignorant novice on basic approach to making this pa

What Marv said, plus instead of bending the rod, make two fittings loosely riveted (but able to turn freely) in the upper half of the arm and use a straight rod with nice acorn nut at the end to keep it from running through.

Mauro Gaetano

in Austin TX

in Austin TX

-

duckman903

- Posts: 326

- Joined: Fri May 28, 2010 3:40 pm

- Location: Winchendon Mass. USA

Re: help ignorant novice on basic approach to making this pa

Why not just make a set of trammel points, if made properly they can have a fine adjustment attached to one of the points. JM$.02W .

- tornitore45

- Posts: 2077

- Joined: Tue Apr 18, 2006 12:24 am

- Location: USA Texas, Austin

Re: help ignorant novice on basic approach to making this pa

Which bring up a learning moment...

Often a problem can be solved by avoiding it altogether and changing the design from slightly to drastically.

Case in point: a spray bar called for a #60 hole 0.9" deep in brass, yea sure.

First the #60 hole is only needed in the center of the part and can be located between two 1/16 holes, second making the part in two pieces and Silver brazing them was a lot easier and less stressful for the operator.

Often a problem can be solved by avoiding it altogether and changing the design from slightly to drastically.

Case in point: a spray bar called for a #60 hole 0.9" deep in brass, yea sure.

First the #60 hole is only needed in the center of the part and can be located between two 1/16 holes, second making the part in two pieces and Silver brazing them was a lot easier and less stressful for the operator.

Mauro Gaetano

in Austin TX

in Austin TX

Re: help ignorant novice on basic approach to making this pa

Yes, indeed. A straight rod is easier to "make" and serves just as well.tornitore45 wrote:What Marv said, plus instead of bending the rod, make two fittings loosely riveted (but able to turn freely) in the upper half of the arm and use a straight rod with nice acorn nut at the end to keep it from running through.

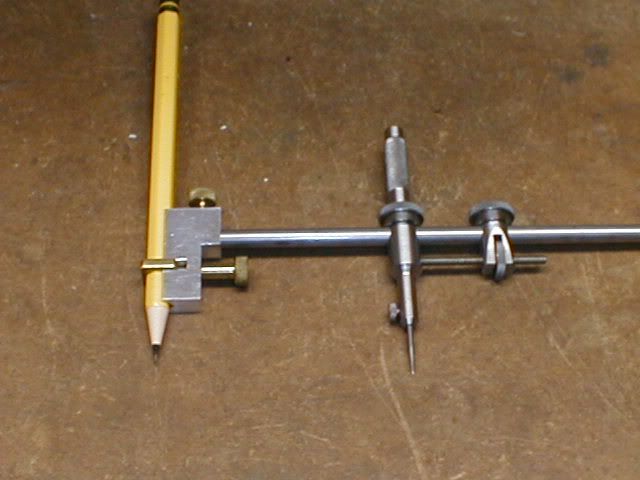

A set of trammel points is also a good, indeed better, idea. Here's a set I made...

Note that the fitting on the left that's shown holding the pencil can also hold an X-acto knife for cutting gaskets, etc. or a center punch for laying out spaced holes. Of course a pointed rod can be used to turn the tool into dividers. Not shown is an extension rod and a fitting for attaching it to the rod shown. With that in place it can draw/cut/punch circles four feet in diameter.

Regards, Marv

Home Shop Freeware

http://www.myvirtualnetwork.com/mklotz

Home Shop Freeware

http://www.myvirtualnetwork.com/mklotz

Re: help ignorant novice on basic approach to making this pa

I think the OP is looking toward learning machining techniques by his question, not how to avoid them by a different design.

Mr.Ron from South Mississippi

Re: help ignorant novice on basic approach to making this pa

Which is why I prefaced my first response with:Mr Ron wrote:I think the OP is looking toward learning machining techniques by his question, not how to avoid them by a different design.

"If you're doing it that way to learn or prove you can, then fine."

Regards, Marv

Home Shop Freeware

http://www.myvirtualnetwork.com/mklotz

Home Shop Freeware

http://www.myvirtualnetwork.com/mklotz

-

jimbarstow

- Posts: 2

- Joined: Wed Nov 26, 2014 11:43 am

Re: help ignorant novice on basic approach to making this pa

I have a very nice set of trammel points that I've used up to this point. They do the job but I've always preferred a compass divider. I like unique tools and the idea of having an out-of-the-ordinary tool that:

1) I like better than what I would normally be use

2) Provides a learning experience

3) Would leave people wondering "Where the hell did he get this?"

is very appealing

1) I like better than what I would normally be use

2) Provides a learning experience

3) Would leave people wondering "Where the hell did he get this?"

is very appealing