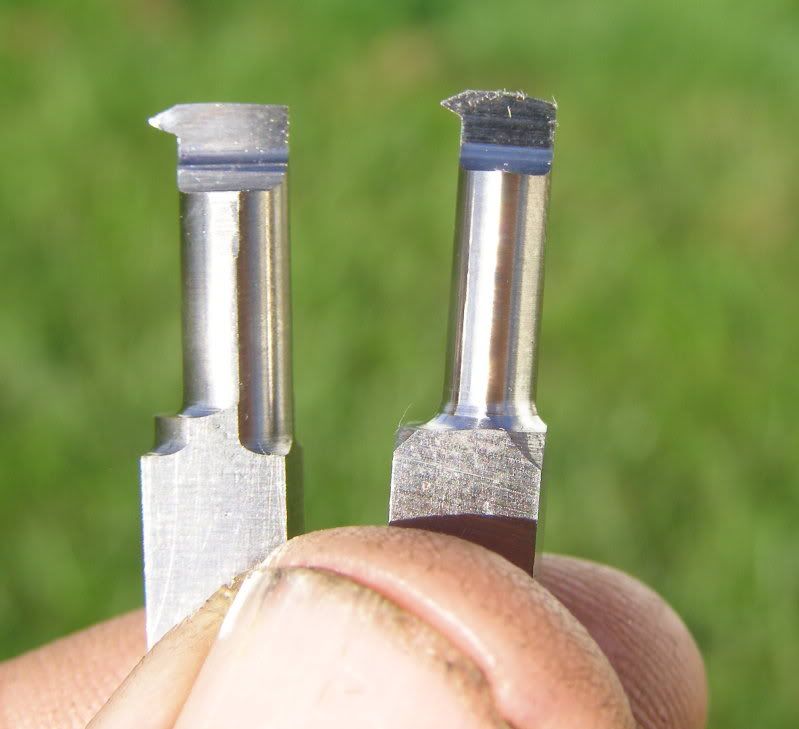

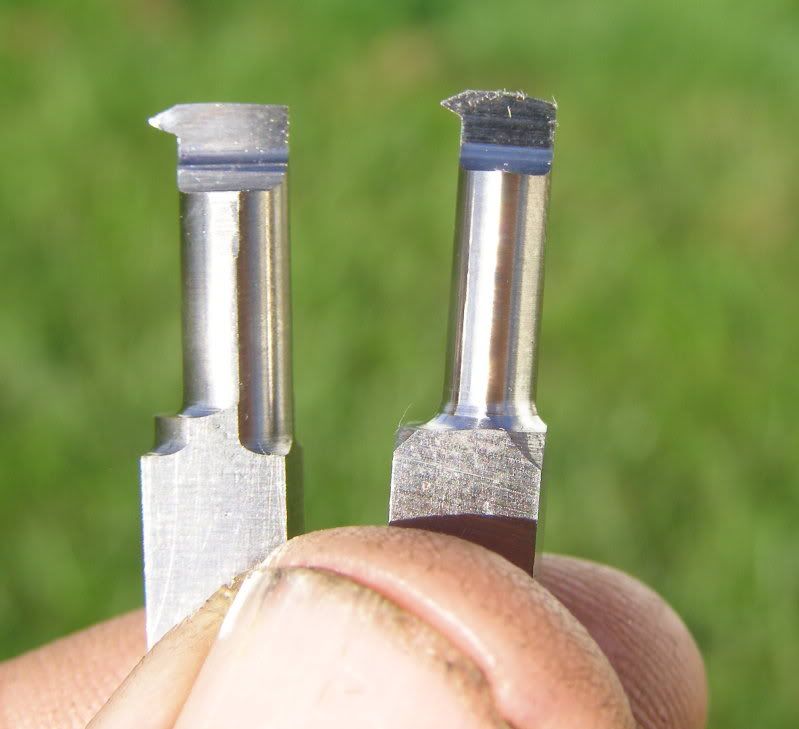

The one on the right is for threading a 1/4" internal thread.

Nearly all of the larger stuff I thread is done with indexable bars and inserts.

Precisely why using a form tool to create the 60° form before heat treating isn't a great idea, although using it to rough, leaving grinding material to create the required relief after heat treat isn't a bad thing. I've always just ground them from HSS square stock, usually 3/8". Larger sizes are discouraged because of the amount of grinding involved.BadDog wrote:I didn't see it mentioned, but you also need to account for lead when grinding. The material below the cutting edge needs to lay down along/inside the developing thread, particularly if you want to maximize support, and more so with smaller diameters and/or faster leads. In fact, the trailing side doesn't need to be ground with much relief at all (though you will want some small amount) as the thread tapering away at lead angle will give you clearance.