Compressor timer switch question

Re: Compressor timer switch question

When I read your original post I immediately thought of my well water pump and pressure tank setup. It pumps up to 50psi and the pressure switch stops the pump, then when the water is used it senses when the pressure is at 40psi and starts the pump again. The water flows from the pump into a pressure tank fitted with a bladder where a certain amount of air is in residence that provides the line pressure between 50 and 40 psi. Why might not something similar work for an air compressor? Just asking.

--earlgo

--earlgo

Before you do anything, you must do something else first. - Washington's principle.

-

John Hasler

- Posts: 1852

- Joined: Tue Dec 06, 2016 4:05 pm

- Location: Elmwood, Wisconsin

Re: Compressor timer switch question

That's how compressors work. The problem comes when something unexpected happens such as a belt getting thrown (has happened to mine) or a ruptured line. Then the motor never stops.

My well pump has a low pressure cutoff: if the tank pressure drops below about 5 psi it shuts down. This prevents basement flooding. A similar feature might be useful on a compressor.

My well pump has a low pressure cutoff: if the tank pressure drops below about 5 psi it shuts down. This prevents basement flooding. A similar feature might be useful on a compressor.

- liveaboard

- Posts: 1986

- Joined: Sun Dec 08, 2013 1:40 pm

- Location: southern Portugal

- Contact:

Re: Compressor timer switch question

Something to remember is that most home shop compressors have unloader valves.

If you use a device other than the pressure switch to stop the power, the unloader valve won't get triggered and when restarted the motor could be stalled [some will melt, ask how I know], or the belt might slip to destruction.

The stopping part is ok; the restart just might need attention.

If you use a device other than the pressure switch to stop the power, the unloader valve won't get triggered and when restarted the motor could be stalled [some will melt, ask how I know], or the belt might slip to destruction.

The stopping part is ok; the restart just might need attention.

-

John Hasler

- Posts: 1852

- Joined: Tue Dec 06, 2016 4:05 pm

- Location: Elmwood, Wisconsin

Re: Compressor timer switch question

Liveaboard writes:

>The stopping part is ok; the restart just might need attention.

A good point. Presumably the system won't time out unless something is wrong, though, so it should be getting attention anyway. The pressure switch on mine has an on/off lever which operates the unloader as well as opening the contacts.

If your compressor motor does not have built-in thermal protection you need a motor starter with the correct heaters. Circuit breakers cannot protect motors.

>The stopping part is ok; the restart just might need attention.

A good point. Presumably the system won't time out unless something is wrong, though, so it should be getting attention anyway. The pressure switch on mine has an on/off lever which operates the unloader as well as opening the contacts.

If your compressor motor does not have built-in thermal protection you need a motor starter with the correct heaters. Circuit breakers cannot protect motors.

- Greg_Lewis

- Posts: 3021

- Joined: Wed Jan 15, 2003 2:44 pm

- Location: Fresno, CA

Re: Compressor timer switch question

Well there have been many useful comments. Thanks everyone. Just to reiterate, the main reason for this solution vs. others is that the compressor is in a separate building from the workshop; hence the desire for something that will take care of itself. (Plus I just don't want to have to deal with it every time I enter or leave the workshop.)

I just realized that John's suggested relay from McMaster is only rated for ten amps while the data plate on the motor says it can draw 15 amps. So a secondary relay rated for the 15 amps would need to be added. Not a big deal. But if a secondary relay is needed, then that opens up the possibility of using a solid state timer with much lower current specs (and possibly lower price) to trip the secondary relay. I see some relays on McMaster's site in the $40 price range that would handle the motor's current.

As to Liveaboard's comments, the scenario I see is this: There is some sort of failure that causes the compressor to come on — a leak anywhere after the compressor itself — in the tank or any of the output lines. The pressure drops and the motor comes on. The timer will only let the motor run for so long before it shuts off.

At this point, because of no pressure in the system the pressure switch remains on, sending voltage to the timer, which keeps the timer in its cycle which happens to have shut the motor off. To restart, the power would have to go off for the timer to reset. To reset, I would have to go to the backshop and trip the breaker. The timer would reset, but so would the pressure switch, and when it turns on the compressor, the unloader would operate normally.

Does all this make sense?

I just realized that John's suggested relay from McMaster is only rated for ten amps while the data plate on the motor says it can draw 15 amps. So a secondary relay rated for the 15 amps would need to be added. Not a big deal. But if a secondary relay is needed, then that opens up the possibility of using a solid state timer with much lower current specs (and possibly lower price) to trip the secondary relay. I see some relays on McMaster's site in the $40 price range that would handle the motor's current.

As to Liveaboard's comments, the scenario I see is this: There is some sort of failure that causes the compressor to come on — a leak anywhere after the compressor itself — in the tank or any of the output lines. The pressure drops and the motor comes on. The timer will only let the motor run for so long before it shuts off.

At this point, because of no pressure in the system the pressure switch remains on, sending voltage to the timer, which keeps the timer in its cycle which happens to have shut the motor off. To restart, the power would have to go off for the timer to reset. To reset, I would have to go to the backshop and trip the breaker. The timer would reset, but so would the pressure switch, and when it turns on the compressor, the unloader would operate normally.

Does all this make sense?

Greg Lewis, Prop.

Eyeball Engineering — Home of the dull toolbit.

Our motto: "That looks about right."

Celebrating 35 years of turning perfectly good metal into bits of useless scrap.

Eyeball Engineering — Home of the dull toolbit.

Our motto: "That looks about right."

Celebrating 35 years of turning perfectly good metal into bits of useless scrap.

- Bill Shields

- Posts: 10589

- Joined: Fri Dec 21, 2007 4:57 am

- Location: 39.367, -75.765

- Contact:

Re: Compressor timer switch question

15 Amps running can well be 100 amp startup.

Too many things going on to bother listing them.

-

John Hasler

- Posts: 1852

- Joined: Tue Dec 06, 2016 4:05 pm

- Location: Elmwood, Wisconsin

Re: Compressor timer switch question

Bill is right. The device that actually switches the power to the motor must be labeled for the motor hp (which is not quite the same thing as being rated for the motor starting current).

Cycling the power makes no difference to the pressure switch: it's purely mechanical and cares only about pressure. However, if the pressure has dropped to zero the unloader doesn't matter.

Cycling the power makes no difference to the pressure switch: it's purely mechanical and cares only about pressure. However, if the pressure has dropped to zero the unloader doesn't matter.

- Greg_Lewis

- Posts: 3021

- Joined: Wed Jan 15, 2003 2:44 pm

- Location: Fresno, CA

Re: Compressor timer switch question

Perhaps we should step back and look at the motor. Below are a couple of pix. The data plate reads 15 amps. The motor is on a 20 amp breaker which never trips. I suspect the breaker is a combo magnetic and thermal, so if there was a startup draw over 20A it should have tripped. So the startup couldn't be more than 20 amps. Do you suppose that it's 15 amps startup? Would a compressor like this really draw 15 amps running? It's only going to 120 psi. I suppose I could try to find someone with a clamp-on ammeter and check the draw.

The plate also claims 5HP. I seem to recall threads in the past about alleged compressor h.p., and I don't think you can tell much by looking at the size of the motor, but nevertheless, it measures only 6 inches in diameter and 9 inches long. I don't see how you could get 5 h.p. out of a motor that small.

The plate also claims 5HP. I seem to recall threads in the past about alleged compressor h.p., and I don't think you can tell much by looking at the size of the motor, but nevertheless, it measures only 6 inches in diameter and 9 inches long. I don't see how you could get 5 h.p. out of a motor that small.

Greg Lewis, Prop.

Eyeball Engineering — Home of the dull toolbit.

Our motto: "That looks about right."

Celebrating 35 years of turning perfectly good metal into bits of useless scrap.

Eyeball Engineering — Home of the dull toolbit.

Our motto: "That looks about right."

Celebrating 35 years of turning perfectly good metal into bits of useless scrap.

-

John Hasler

- Posts: 1852

- Joined: Tue Dec 06, 2016 4:05 pm

- Location: Elmwood, Wisconsin

Re: Compressor timer switch question

Circuit breakers don't trip instantly when their rated current is exceeded. They integrate (a function of) the current over time. The startup current for that motor is certainly more than 20 amp. Compressor motors need to deliver high starting torque which means high starting current.

What is the compressor rated for? The motor will reach full load just as the pressure reaches that value.

What is the compressor rated for? The motor will reach full load just as the pressure reaches that value.

Re: Compressor timer switch question

OK... this thread seems a bit silly. First, I think you need to take a step even further back and determine what the current control system is on the compressor. Then determine what the power requirements are for the motor and determine if you can/cannot pass that thru a timer or need an external switching device. Then you can finalize your timer choice based on mounting/package options and whether you want a fixed interval or something with adjustable time/repeat action.

1) Your motor does not appear to be a true 5HP motor. 15A at 230V is a bit small, about 4HP or so. A number of compressors several years ago were grossly overrated claiming that "instantaneous startup power" was the HP, not the continuous 2 or 3HP the motor actually produced. A true 5HP motor will run about 16-18A on the line at full load and have a plate rating of 21-24A depending on its service factor.

2) When looking at timers/relays/contactors you need to carefully look at the actual specs on the device (if you want to to survive many years with heavy use at least). The maximum rating shown is the rating driving a resistive load at a given supply voltage. The rating at different voltages and with load characteristics may be significantly less. So, for instance, a 25A relay might be rated for 25A at 120V AC with a resistive load. But at 240V AC it might be rated at 22A resistive and only 13A or 3HP with an inductive/motor load.

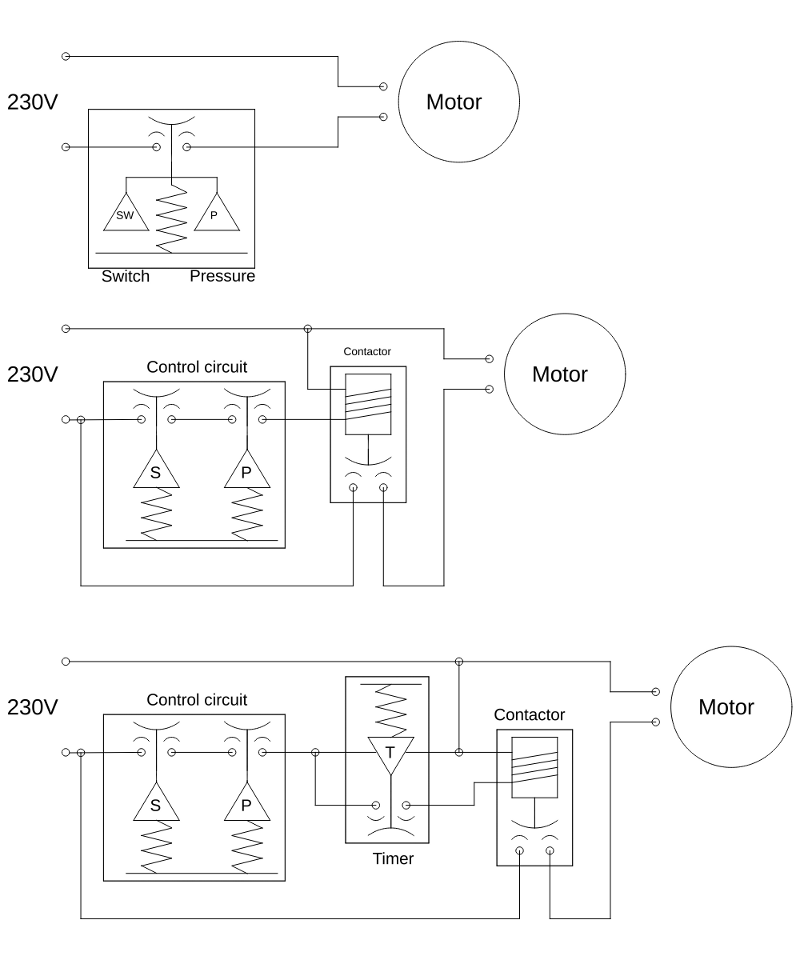

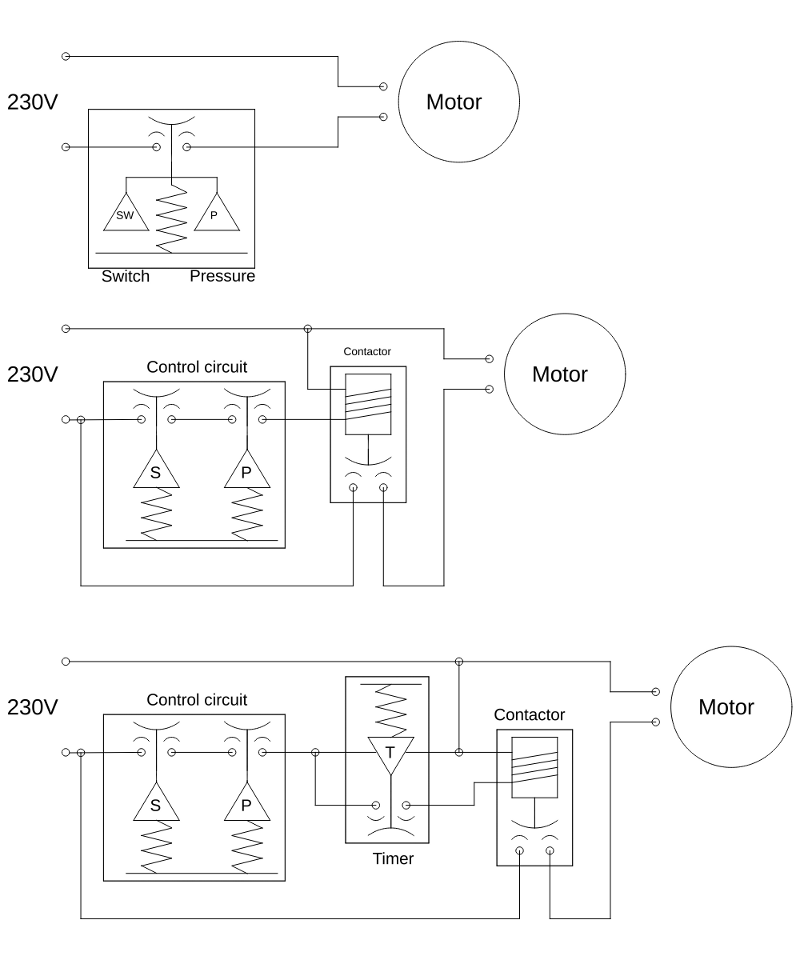

3) You need to determine the control circuit currently on your compressor and how you want to expand that. The simplest setup is a combined power and pressure switch with a single contact. The power switch (or level) often just mechanically holds the pressure switch open when "off" and the pressure switch takes all the load of switching the motor current. In this setup, if retained, you would need the timer to be able to handle the full load of the motor switching on and off.

In better setups, there are discreet power and pressure switches which form a control circuit that drives a contactor which takes the load of the motor. The switches (and added timer) be rated far less as they only need to drive the power needed to actuate the contactor coil, not the motor. In some cases the control circuit may be a low voltage as well (i.e. transformer stepped-down 24VAC control circuit on a 240V line), which further reduced the rating required. In the best setups, the control circuit will drive a motor starter, a heavy duty contactor with built in overload sensing and trip, and possibly auxiliary contact for driving other control circuits.In the 5HP compressor I built I opted for the later, a starter and control circuit that allowed me to have an on/off switch, indicator light, remote pressure switch, and overload protection. When I get to it I plan on adding on auto-purge and dessicant recharge circuit when the motor stops.

4) You can choose from several different timer options depending on how fancy you want to get. Most likely you want a simple interval timer which immediately turns the output on when powered up, and the turns the output back off when the timer expires. Removing power from the timer resets the clock. A MCMaster 6964K4 DIN mount timer would work, if a bit more complicated than you need(its a multi-function timer). You are a bit limited in timers as most will be 12-24VAC or 120VAC input for control circuits, but there are 240VAC versions as well. You could also use the NC contact of a delayed-start (aka. power-on delay) timer to accomplish the same thing, or perhaps a cycle timer if you wanted to have the compressor cycle on/off repeatedly. See the McMaster page for a basic timing diagram of input power vs output state: https://www.mcmaster.com/timers/din-rai ... -relays-7/

Something like an Omron H3CR is a socket mount multifunction timer that comes in a whole bunch of different power ratings(and probably more than you need). I have several in my workshop rated for 120-240V that I used to build a temporary multi-day/multi-cycle irrigation pump controller years ago. Something like an Omron H3DS-AL-AC24-230 might be more appropriate. Omron and some other manufacturers had some tab mount packaged timer relays, that looked a lot like automotive relays, with 1/4" spade connectors, but Ican't seem to find the part numbers at the moment.

5) Basically, you need to insert the timer after the pressure switch/control circuit. That should provide power, when air pressure is demanded, to the timer.The timer will then activate and supply power to the motor (preferably thru a contactor). When the timer expires the supply to the motor will be cut, even if the pressure switch is still activated. When the pressure switch opens, the timer loses power, resets, and automatically opens supply to the motor.

1) Your motor does not appear to be a true 5HP motor. 15A at 230V is a bit small, about 4HP or so. A number of compressors several years ago were grossly overrated claiming that "instantaneous startup power" was the HP, not the continuous 2 or 3HP the motor actually produced. A true 5HP motor will run about 16-18A on the line at full load and have a plate rating of 21-24A depending on its service factor.

2) When looking at timers/relays/contactors you need to carefully look at the actual specs on the device (if you want to to survive many years with heavy use at least). The maximum rating shown is the rating driving a resistive load at a given supply voltage. The rating at different voltages and with load characteristics may be significantly less. So, for instance, a 25A relay might be rated for 25A at 120V AC with a resistive load. But at 240V AC it might be rated at 22A resistive and only 13A or 3HP with an inductive/motor load.

3) You need to determine the control circuit currently on your compressor and how you want to expand that. The simplest setup is a combined power and pressure switch with a single contact. The power switch (or level) often just mechanically holds the pressure switch open when "off" and the pressure switch takes all the load of switching the motor current. In this setup, if retained, you would need the timer to be able to handle the full load of the motor switching on and off.

In better setups, there are discreet power and pressure switches which form a control circuit that drives a contactor which takes the load of the motor. The switches (and added timer) be rated far less as they only need to drive the power needed to actuate the contactor coil, not the motor. In some cases the control circuit may be a low voltage as well (i.e. transformer stepped-down 24VAC control circuit on a 240V line), which further reduced the rating required. In the best setups, the control circuit will drive a motor starter, a heavy duty contactor with built in overload sensing and trip, and possibly auxiliary contact for driving other control circuits.In the 5HP compressor I built I opted for the later, a starter and control circuit that allowed me to have an on/off switch, indicator light, remote pressure switch, and overload protection. When I get to it I plan on adding on auto-purge and dessicant recharge circuit when the motor stops.

4) You can choose from several different timer options depending on how fancy you want to get. Most likely you want a simple interval timer which immediately turns the output on when powered up, and the turns the output back off when the timer expires. Removing power from the timer resets the clock. A MCMaster 6964K4 DIN mount timer would work, if a bit more complicated than you need(its a multi-function timer). You are a bit limited in timers as most will be 12-24VAC or 120VAC input for control circuits, but there are 240VAC versions as well. You could also use the NC contact of a delayed-start (aka. power-on delay) timer to accomplish the same thing, or perhaps a cycle timer if you wanted to have the compressor cycle on/off repeatedly. See the McMaster page for a basic timing diagram of input power vs output state: https://www.mcmaster.com/timers/din-rai ... -relays-7/

Something like an Omron H3CR is a socket mount multifunction timer that comes in a whole bunch of different power ratings(and probably more than you need). I have several in my workshop rated for 120-240V that I used to build a temporary multi-day/multi-cycle irrigation pump controller years ago. Something like an Omron H3DS-AL-AC24-230 might be more appropriate. Omron and some other manufacturers had some tab mount packaged timer relays, that looked a lot like automotive relays, with 1/4" spade connectors, but Ican't seem to find the part numbers at the moment.

5) Basically, you need to insert the timer after the pressure switch/control circuit. That should provide power, when air pressure is demanded, to the timer.The timer will then activate and supply power to the motor (preferably thru a contactor). When the timer expires the supply to the motor will be cut, even if the pressure switch is still activated. When the pressure switch opens, the timer loses power, resets, and automatically opens supply to the motor.

- Greg_Lewis

- Posts: 3021

- Joined: Wed Jan 15, 2003 2:44 pm

- Location: Fresno, CA

Re: Compressor timer switch question

Choprboy:

THANK YOU for your detailed response. I didn't think this motor could be a genuine 5 h.p. Earlier this evening I found a calculator on the web wherein you put in the electrical requirements and it gives you a h.p. rating. While I'm not sure I did it right, the answer that came back was between 3 and 4 h.p. which seems more probable for this compressor (I forget the exact value).

Regardless, I'll spend some time tomorrow with your post and study your recommendations. (My brain doesn't work too well in the late evenings!) A solution is close at hand!

THANK YOU for your detailed response. I didn't think this motor could be a genuine 5 h.p. Earlier this evening I found a calculator on the web wherein you put in the electrical requirements and it gives you a h.p. rating. While I'm not sure I did it right, the answer that came back was between 3 and 4 h.p. which seems more probable for this compressor (I forget the exact value).

Regardless, I'll spend some time tomorrow with your post and study your recommendations. (My brain doesn't work too well in the late evenings!) A solution is close at hand!

Greg Lewis, Prop.

Eyeball Engineering — Home of the dull toolbit.

Our motto: "That looks about right."

Celebrating 35 years of turning perfectly good metal into bits of useless scrap.

Eyeball Engineering — Home of the dull toolbit.

Our motto: "That looks about right."

Celebrating 35 years of turning perfectly good metal into bits of useless scrap.

- Greg_Lewis

- Posts: 3021

- Joined: Wed Jan 15, 2003 2:44 pm

- Location: Fresno, CA

Re: Compressor timer switch question

The obvious: I'll see if any of my neighbors have a clamp-on ammeter I could borrow for a few minutes and check the actual current draw of the motor. Duh. Then we'll proceed.

Greg Lewis, Prop.

Eyeball Engineering — Home of the dull toolbit.

Our motto: "That looks about right."

Celebrating 35 years of turning perfectly good metal into bits of useless scrap.

Eyeball Engineering — Home of the dull toolbit.

Our motto: "That looks about right."

Celebrating 35 years of turning perfectly good metal into bits of useless scrap.