tool grinding woes.

-

thomas harris

- Posts: 384

- Joined: Thu Jul 26, 2007 6:02 pm

- Location: michigan

tool grinding woes.

I spent a bit of time last night trying to get a lathe tool to cut. Turning some 1/2 drill rod oil hardening. It squeals and leaves a "beaver chewed" finish. The shavings were like I've never seen yet. Looked like a saw blade. This comes off the heels of grinding a bit that worked beautifully on the same stock. Nice finsh. Nice light cuts, heavy cuts, and in between. I just walked away from the whole mess last night. My supply of hss tool blanks is going to get low fast if I keep trashing them. This was a humbling experience. I may get back in the ring soon, but right now the metal has won a round. Is there a good video on tool bit sharpening? This tool geometry stuff is fasinating and frustrating.

Re: tool grinding woes.

Not until someone gets over to Harold's with a camcorderthomas harris wrote:Is there a good video on tool bit sharpening?

Steve

like edge says, need more info. do you have the basics of geometry down? the simple stuff, ie front and side clearance so it doesn't rub and top rake? mostly, the angles have a lot of latitude - you can be pretty far off and it will still work.

have you calculated your speed? use a surface speed of say 80 or less for drill rod with hss - other than production rate, it doesn't hurt to go less. cutting drill is tough, but a well ground tool taking an appropriate cut (based on the lathes capability) should leave a good finish.

Assuming you not working with a piece of hardened steel or something that can't be cut, its a short list that can go wrong, start ticking them off.

-tool at centre height

-amount of rake

-side and front clearance

-right speed

depth and feed are refinements, but the above is the more basic, will it cut.

good part is hss blanks are cheap and easy to regrind. or grind away a piece of 1/4" HR if you really think you need remedial practice

have you calculated your speed? use a surface speed of say 80 or less for drill rod with hss - other than production rate, it doesn't hurt to go less. cutting drill is tough, but a well ground tool taking an appropriate cut (based on the lathes capability) should leave a good finish.

Assuming you not working with a piece of hardened steel or something that can't be cut, its a short list that can go wrong, start ticking them off.

-tool at centre height

-amount of rake

-side and front clearance

-right speed

depth and feed are refinements, but the above is the more basic, will it cut.

good part is hss blanks are cheap and easy to regrind. or grind away a piece of 1/4" HR if you really think you need remedial practice

-

Skeeter5000

Tool grinding

Good luck on getting the hang of using hss.

Try this site, it has some good info about tool grinding, also.

http://www.sherline.com/grinding.htm

Try this site, it has some good info about tool grinding, also.

http://www.sherline.com/grinding.htm

Re: tool grinding woes.

Blue in color? If not, signs of excessive heat, in spite of spindle speed? Well supported in the chuck? Turning round, not multiple sided?thomas harris wrote:I spent a bit of time last night trying to get a lathe tool to cut. Turning some 1/2 drill rod oil hardening. It squeals and leaves a "beaver chewed" finish. The shavings were like I've never seen yet. Looked like a saw blade.

Sounds like the tool isn't clearing properly. Inspect the tool for side and front clearance---if it's dragging, you should see definite signs of rubbing on the tool. Increase relief angle, and do it in one common plane if possible. If you have more than one grind, it's entirely possible the tool, at a glance, will appear to have ample clearance, but can be dragging the tiniest amount directly under the cutting edge. That condition increases heating tremendously, often stopping the cut entirely. From this, you should infer that the relief must go to the cutting edge, it can not terminate below.

The other consideration is if you have rounded the cutting edge in the process of grinding either the rake angle, or a chip breaker. A narrow band of zero rake is acceptable to extend the useful life of the cutting edge, but make sure you haven't gone negative with HSS----it won't tolerate that condition well at all for the material in question.

Don't expect to master tool grinding in a few short days. It's a skill that grows constantly----you'll be far better next year than you are today.

Can you post a picture of the problematic tool?

Harold

-

thomas harris

- Posts: 384

- Joined: Thu Jul 26, 2007 6:02 pm

- Location: michigan

Well I went back out to my shop. I looked a bit closer at the problem tool. There is indeed a "rub ground" spot on the side of it. I was apparently too overly concerned with bottom clearance angle and neglected the side clearance. Gave the side a bit of relief and it cut like a champ. I'm an old dog, and these new tricks don't come easy! Thanks to all for the suggested solutions, and next time I'll try to give more details on the situation. I'm hoping the basics of this tool angle stuff will start to be clearer with time. Incidently, most of the inaccuracies I mentioned earlier about my machine were caused by turning with a tail center not properly centered and with a chuck on the headstock instead of another center. I am finding acurracy to within -+.ooo3, which is ok for now with what I am doing with it. It's still way easy to "blow it" and overcut the part to the point of staring over, but I suppose that's part of the program in machining work.

-

JimGlass

- Posts: 2281

- Joined: Sat Jan 04, 2003 8:33 pm

- Location: 40 Miles West of Chicago/near DeKalb

- Contact:

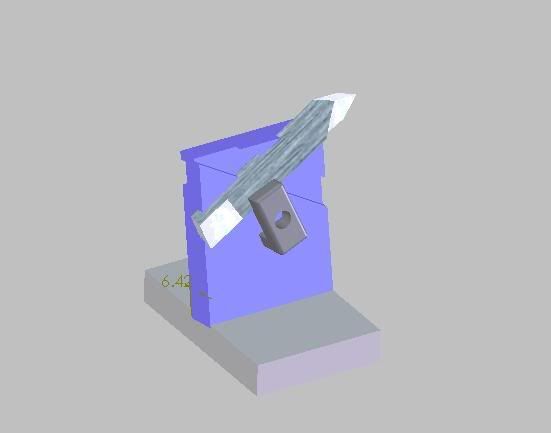

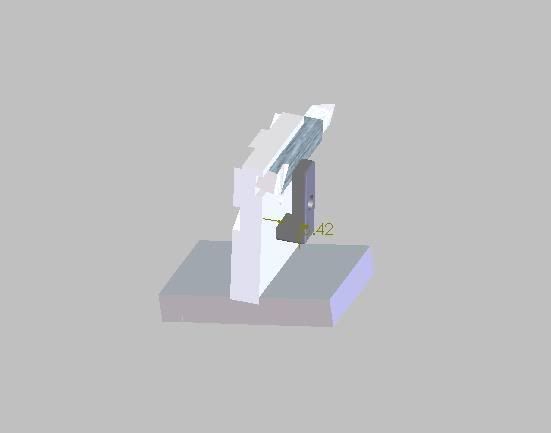

Is this any help?

Looking closely at the cutting edge of any tool usually tells a story of how well the tool is cutting. Abrasion marks on the side of a tool indicates the lack of clearance. Lathe tools need to always be on center of the the workpiece.

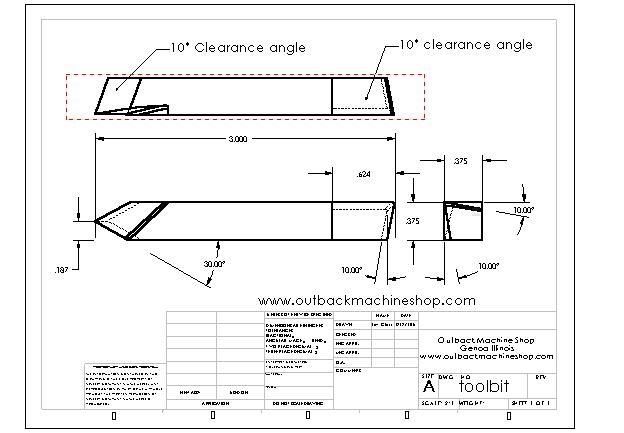

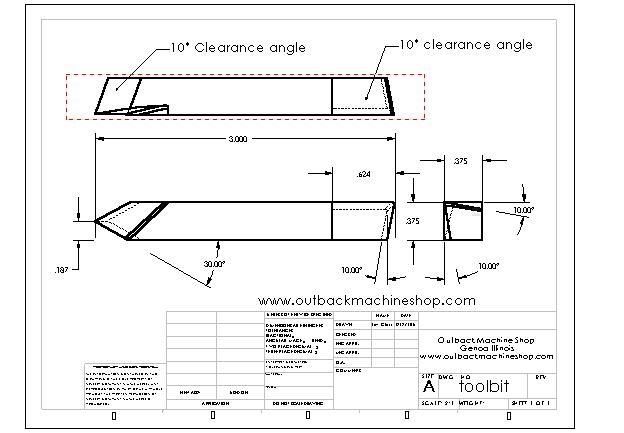

toolbit drawing.

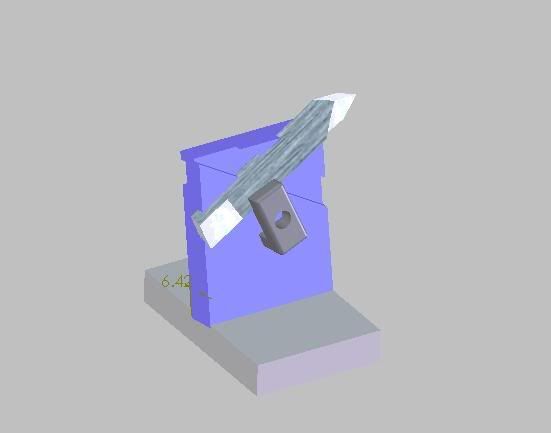

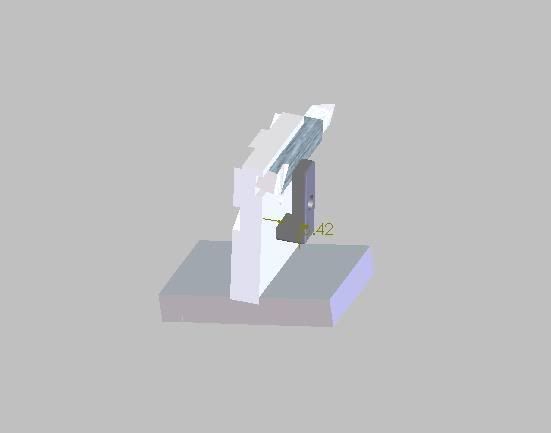

A fixture I made for sharpening toolbits on a surface grinder. I made it mostly to utilize coolant while grinding. Really saves the fingers when roughing in a new toolblank

Jim

Looking closely at the cutting edge of any tool usually tells a story of how well the tool is cutting. Abrasion marks on the side of a tool indicates the lack of clearance. Lathe tools need to always be on center of the the workpiece.

toolbit drawing.

A fixture I made for sharpening toolbits on a surface grinder. I made it mostly to utilize coolant while grinding. Really saves the fingers when roughing in a new toolblank

Jim

Tool & Die Maker/Electrician, Retired 2007

So much to learn and so little time.

www.outbackmachineshop.com

So much to learn and so little time.

www.outbackmachineshop.com

Speaking as another old dog, part of the problem is often our lack of ability to see clearly what we're doing. I had vision that was the envy of everyone until age 45. I could grind a form within a thou with some concentration----but those days are now gone.thomas harris wrote: I'm an old dog, and these new tricks don't come easy!

I'm of the impression that you're doing quite well---do not get discouraged. Some people never master the process of grinding tools that cut well----some of them even work in the trade. The important thing is to understand how a tool cuts, and why. Once you have that down, the rest is simply training your hands to guide the tool properly. It comes only from experience, you can't learn it by reading.

The rub area you discovered is a great example of the learning curve. Now when you find a tool isn't performing as expected, you have one more indicator that you have identified as the probable cause. The best and easiest ways to learn these things is by example.

Harold

-

thomas harris

- Posts: 384

- Joined: Thu Jul 26, 2007 6:02 pm

- Location: michigan

thomas harris wrote: I'm an old dog, and these new tricks don't come easy!

Harold_V wrote:Speaking as another old dog, part of the problem is often our lack of ability to see clearly what we're doing. I had vision that was the envy of everyone until age 45. I could grind a form within a thou with some concentration----but those days are now gone.

Yes, my eyes are not the ones I was originally issued. When I was in high school I could outshoot anyone on the block with a rifle. Now it's telescopic sights just to get a medicore group. Just thankful I can afford corrective lenses to at least minimize the problem. I work in a pressroom on my "day job", and that too becomes more and more challenging with older eyes. The big advantage there is I know WHAT to look for before I see it. I have seen almost all of the ink or register problems by now. Almost. I still find plenty of stuff the folks with no glasses and sharp vision miss.