1018 for Tool Holders?

- SteveHGraham

- Posts: 7788

- Joined: Sat Jan 17, 2009 7:55 pm

- Location: Florida

1018 for Tool Holders?

I now have a fairly decent pile of metal to help me learn to use machine tools. In addition to the stuff Lakeside53 sent, I got some 360 brass, a long A2 rod, a long 304 rod, some 12L14, and a big chunk of 1018. I decided to buy the weird piece of 8740 I wrote about a few days ago. It may be too hard to machine, but it was so cheap, I figured it wouldn't hurt to take a look.

The 1018 looks just like a loaf of government cheese, except it's metal. It's about 16" long and 4" on a side. I was hoping to make some tool holders, and this was the cheapest big hunk of steel I could find.

Is there any hope I'll be able to produce decent tool holders from this? I've been reading about 1018's machinability, and it doesn't sound ideal. I was hoping it would be okay, since tool holders don't have to be works of art.

The 1018 looks just like a loaf of government cheese, except it's metal. It's about 16" long and 4" on a side. I was hoping to make some tool holders, and this was the cheapest big hunk of steel I could find.

Is there any hope I'll be able to produce decent tool holders from this? I've been reading about 1018's machinability, and it doesn't sound ideal. I was hoping it would be okay, since tool holders don't have to be works of art.

Every hard-fried egg began life sunny-side up.

- SteveHGraham

- Posts: 7788

- Joined: Sat Jan 17, 2009 7:55 pm

- Location: Florida

- Frank Ford

- Posts: 594

- Joined: Sun Dec 16, 2007 12:41 pm

- Location: Palo Alto, CA

- Contact:

I've made a number of tool holders from 1018, and find it's just great for the use.

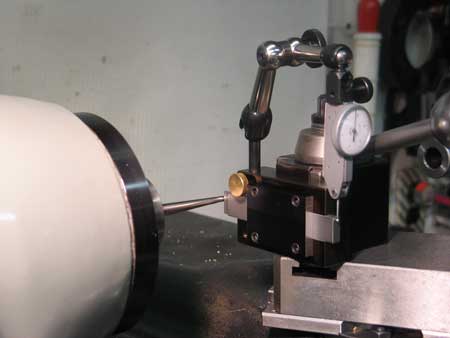

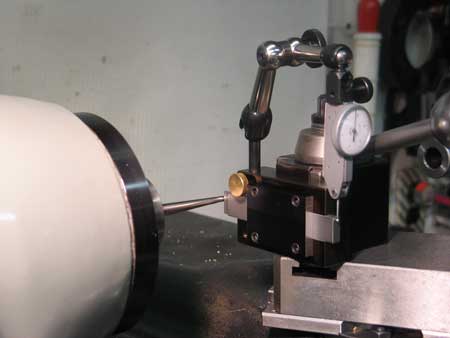

This is my most useful one:

To see how I made it and how I use it:

http://www.frets.com/HomeShopTech/Tooli ... older.html

Here's a circular form tool holder:

I did an article on it, too:

http://www.frets.com/HomeShopTech/Tooli ... older.html

In fact, I've made and plan to make enough others that I've posted instructions for making them using the DRO on the mill and an insert dovetail cutter. It's on the back of the tool holder drawer itself:

This is my most useful one:

To see how I made it and how I use it:

http://www.frets.com/HomeShopTech/Tooli ... older.html

Here's a circular form tool holder:

I did an article on it, too:

http://www.frets.com/HomeShopTech/Tooli ... older.html

In fact, I've made and plan to make enough others that I've posted instructions for making them using the DRO on the mill and an insert dovetail cutter. It's on the back of the tool holder drawer itself:

Cheers,

Frank Ford

Frank Ford

- SteveHGraham

- Posts: 7788

- Joined: Sat Jan 17, 2009 7:55 pm

- Location: Florida

- mechanicalmagic

- Posts: 1431

- Joined: Sun Nov 04, 2007 12:11 am

- Location: Pleasanton, CA Land of perfect weather

Steve,

If I was making tool holders from 1018, I would: After machining, improve the surface with sand paper on a "surface plate" (OK, a piece of marble floor tile). Then I would use gun blue. It seems to provide a hard surface, and it holds oil so the parts don't rust as fast.

Dave J.

If I was making tool holders from 1018, I would: After machining, improve the surface with sand paper on a "surface plate" (OK, a piece of marble floor tile). Then I would use gun blue. It seems to provide a hard surface, and it holds oil so the parts don't rust as fast.

Dave J.

Every day I ask myself, "What's the most fun thing to do today."

9x48 BP clone, 12x36 lathe, TIG, MIG, Gas, 3 in 1 sheetmetal.

9x48 BP clone, 12x36 lathe, TIG, MIG, Gas, 3 in 1 sheetmetal.

- Frank Ford

- Posts: 594

- Joined: Sun Dec 16, 2007 12:41 pm

- Location: Palo Alto, CA

- Contact:

Just to add to mechanicalmagic's suggestion: the "cold bluing" available at most any sporting goods place (that carries guns) is a fast and easy way to improve the look and slighly improve the rust resistance (once oiled) of your holders. Super fast and simple -- just make sure you've washed the parts clear of oil first. True gun bluing might add a tiny bit of hardness, but I doubt the cold blue has any significant effect.

It is generally accepted that the percentage of carbon in mild steel does not allow for hardening. Recent reports on proper quenching tend to discount the idea, but for all practical purposes, mild steel is not heat treatable by conventional methods.SteveHGraham wrote:Do you recommend hardening a 1018 holder?

Assuming you have intentions, you have options. The material responds reasonably well to pack hardening, or it can be hardened superficially by using one of the available cyanide products. Depth of hardness by the cyanide method will be limited, but you can achieve an Rc 62 hardness of .06" depth by pack hardening. A furnace is required.

Heat treat is an art---not well understood by the masses.

Edit:

The real advantage of heat treating shop tools is the resistance to deformation. Soft materials tend to degrade in use, both by displacement from clamping pressure and when bumped. By heat treating, the original form and precision features are better protected. I recommend heat treatment if the tool is intended for prolonged use. In that case, a better choice of material would be 4140, which machines similar to 1018, although with more abrasion of the cutting tool.

Harold

4140 Q&T (pre-hard) square bar is available and machines quite nicely. Much nicer finish than 1018, tougher, and is around 30 Rockwell C hardness. (but not always)

http://www.suppliersonline.com/recentRF ... loy+Steels

http://www.suppliersonline.com/recentRF ... loy+Steels

Glenn

Operating machines is perfectly safe......until you forget how dangerous it really is!

Operating machines is perfectly safe......until you forget how dangerous it really is!

- mechanicalmagic

- Posts: 1431

- Joined: Sun Nov 04, 2007 12:11 am

- Location: Pleasanton, CA Land of perfect weather

PeteM,PeteM wrote:True gun bluing might add a tiny bit of hardness, but I doubt the cold blue has any significant effect.

While I agree that the surface provided by cold blue has very little depth, I believe it has significant hardness.

I base this on the procedure. After bluing, the part is routinely rubbed vigorously with steel wool. Before bluing, this would result in a significant change in the surface finish, scratching the surface, albeit smooth, but changing the pattern. After bluing, it only removes the dullness.

I blue a lot of stuff, cheap and easy.

Dave J.

Every day I ask myself, "What's the most fun thing to do today."

9x48 BP clone, 12x36 lathe, TIG, MIG, Gas, 3 in 1 sheetmetal.

9x48 BP clone, 12x36 lathe, TIG, MIG, Gas, 3 in 1 sheetmetal.

Dave. Could be. My own experience with Birchwood Casey cold blue is that a file bites in about the same either raw or cold blued. Still, I've also noticed what you're talking about. Started to try a test, but my Rockwell tester isn't the superficial type and probably won't show the surface hardness. Petemechanicalmagic wrote: . . I believe it has significant hardness.