Workholding Device for Horizontal Band Saw

- SteveHGraham

- Posts: 7788

- Joined: Sat Jan 17, 2009 7:55 pm

- Location: Florida

Workholding Device for Horizontal Band Saw

I am making a gun part out of a block of 1045, and the other day it occurred to me that it would be great if I could use my band saw instead of roughing out huge amounts of steel. But the band saw won't hold small parts.

Surely someone else has had this thought, and there must be a time-tested workholding device that will do the job. Am I right, or do I have to make one up?

I have some 4x4 aluminum bar stock. I was thinking a short section of that could go in the saw's vise, and then I could put some kind of clampy deal on the end of it to hold parts.

Surely someone else has had this thought, and there must be a time-tested workholding device that will do the job. Am I right, or do I have to make one up?

I have some 4x4 aluminum bar stock. I was thinking a short section of that could go in the saw's vise, and then I could put some kind of clampy deal on the end of it to hold parts.

Every hard-fried egg began life sunny-side up.

Re: Workholding Device for Horizontal Band Saw

You've not made it clear what the real problem is. (Edit: I just reread the heading. I now realize you're talking about a horizontal, but here's some useful information)

If you are speaking of a vertical saw, and you have problems with small items dragging in to the relatively large opening in which the blade runs, simply saw a thin piece of material that is large enough to support the work piece. You then use the thin piece as the necessary support base to prevent your part from being dragged through the opening.

If your problem is holding a relatively short piece in the vise of a horizontal saw, the fix is easy. It does require that you have a piece of material that is the same size as the part to be held.

Using a couple pieces of flat stock that are at least as long as the vise jaws are wide, place one against the fixed jaw of your saw vise, and one against the moveable jaw. Extend them to the point where they almost contact the blade. Locate the piece to be sawn at the appropriate place, then install the second piece of material at the opposite end of the work piece, so it will prevent the moveable jaw from pivoting. Done.

You may find that you can C clamp the work to the machine, too. If that's your choice, make sure the material bears on the fixed jaw, to help prevent movement. If the work piece shifts, even a little, it's likely to destroy the blade.

Harold

If you are speaking of a vertical saw, and you have problems with small items dragging in to the relatively large opening in which the blade runs, simply saw a thin piece of material that is large enough to support the work piece. You then use the thin piece as the necessary support base to prevent your part from being dragged through the opening.

If your problem is holding a relatively short piece in the vise of a horizontal saw, the fix is easy. It does require that you have a piece of material that is the same size as the part to be held.

Using a couple pieces of flat stock that are at least as long as the vise jaws are wide, place one against the fixed jaw of your saw vise, and one against the moveable jaw. Extend them to the point where they almost contact the blade. Locate the piece to be sawn at the appropriate place, then install the second piece of material at the opposite end of the work piece, so it will prevent the moveable jaw from pivoting. Done.

You may find that you can C clamp the work to the machine, too. If that's your choice, make sure the material bears on the fixed jaw, to help prevent movement. If the work piece shifts, even a little, it's likely to destroy the blade.

Harold

- SteveHGraham

- Posts: 7788

- Joined: Sat Jan 17, 2009 7:55 pm

- Location: Florida

Re: Workholding Device for Horizontal Band Saw

I'm kind of surprised no one sells a prefab doodad to do this for me.

Every hard-fried egg began life sunny-side up.

Re: Workholding Device for Horizontal Band Saw

I've read about some people using small vices mounted to what-not for that. I have thought about building a swivel mount of some wort to fit on the end of a short hunk of 2x2 12 gauge tube to mount a 2" or 3" drill press vice. Cutting small stuff on my HF band saw is almost impossible.

Chris -

http://raceabilene.com/kelly/hotrod

"Check all parts for proper condition before operation; if normal safety precautions are noticed carefully, this machine can provide you withstanding of accurate service."

http://raceabilene.com/kelly/hotrod

"Check all parts for proper condition before operation; if normal safety precautions are noticed carefully, this machine can provide you withstanding of accurate service."

Re: Workholding Device for Horizontal Band Saw

Early this winter I needed to make some tapered D washers with 3/4"+ ID, 1.32 OD and with thickness going from 5/32" to 1/16". I turned a bit of waste stock, used the mill to cut in the D flat then started to part off the washers. After the parting bit broke on the flat I decided to use the horizontal band saw. The problem was how do I hold a 2 1/2 inch piece of stock so I could cut 6 or 7 3/16" thick washers. I ended up screwing a 6" diameter 4 jaw lathe chuck to a 8" right angle plate and clamping that in the bandsaw vice. It worked well. I sliced off the washers then ground in the taper with a belt sander while wished I had the surface grinder set up and working. Having done that once I'd do it again. I found that with the 4-jaw you can securely hold a short irregularly shaped part very close to the blade.

Tom

Tom

-

Jay, Idaho

- Posts: 124

- Joined: Wed Jul 26, 2006 3:03 pm

Re: Workholding Device for Horizontal Band Saw

Sometimes the easiest method is to weld your part to a bar and put the bar in the vise. I have about 8 toolmaker vises in several sizes and these are quite handy for holding small parts.

Maybe drill a hole in the part and use a screw to hold it to a bar for sawing. The hole would have to be where it would not remain in the finished part.

Maybe drill a hole in the part and use a screw to hold it to a bar for sawing. The hole would have to be where it would not remain in the finished part.

Re: Workholding Device for Horizontal Band Saw

I do that all the time. Just 2(?) weeks back, I tacked a piece of 2" plate, about 10" x 16", to a piece of 1/2 plate that was about 10" x 20". See, the 2" plate needed cutting to produce a slab 10" x 3". But my bandsaw will barely cut 10", and the vise won't open that large, so I removed the vise and clamped the 1/2 plate directly to the saw base. I've got lots of smallish drops/pieces of 16 ga 1" square tube that I also use for "handles" to hold odd parts in the saws. Or I use an old $10 vise I got at a yard sale. It has 3 ground/square sides with about 2" wide jaws. Turn it on it's side or end and clamp that in the saw vise. I've used v-blocks, clamps, all sorts of stuff.Jay, Idaho wrote:Sometimes the easiest method is to weld your part to a bar and put the bar in the vise. I have about 8 toolmaker vises in several sizes and these are quite handy for holding small parts.

Maybe drill a hole in the part and use a screw to hold it to a bar for sawing. The hole would have to be where it would not remain in the finished part.

Russ

Master Floor Sweeper

Master Floor Sweeper

Re: Workholding Device for Horizontal Band Saw

There are lots of devices - I have made several. On a large saw such as a 7 x 12 you can simply put the part in a smaller vise (I use a drill press vice) and then clamp the vise in the saw vise.

On my old 4 x 6 saw which was too small to hold a drill press vice, I made a small parts holder with two pieces of bar stock and a threaded rod. The picture is looking down at the top of the bar stock. The red rectangle is the part placed at one end of the pieces of bar and the threaded rod is used to make the distance at the other end the same width. This assembly is put in your vice which then applies the clamping force.

On my old 4 x 6 saw which was too small to hold a drill press vice, I made a small parts holder with two pieces of bar stock and a threaded rod. The picture is looking down at the top of the bar stock. The red rectangle is the part placed at one end of the pieces of bar and the threaded rod is used to make the distance at the other end the same width. This assembly is put in your vice which then applies the clamping force.

- Mark Hockett

- Posts: 270

- Joined: Wed Feb 20, 2008 8:46 pm

- Location: Clinton WA.

Re: Workholding Device for Horizontal Band Saw

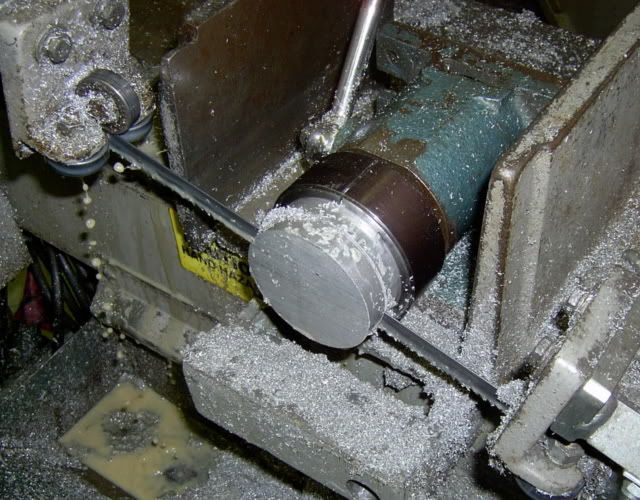

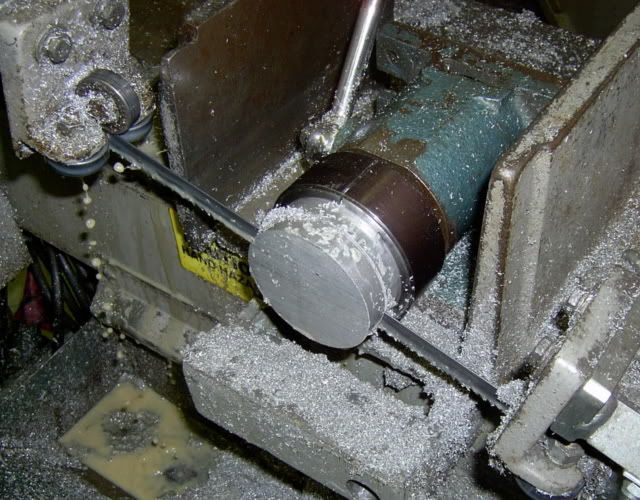

I like to use a 5C collet chuck in my saw for odd stuff. Here's some pictures of a job I did,

And when I was done on the saw the collet went right in the lathe,

And when I was done on the saw the collet went right in the lathe,

Mark Hockett

- 737mechanic

- Posts: 373

- Joined: Thu Jun 04, 2009 6:27 pm

- Location: Dallas

Re: Workholding Device for Horizontal Band Saw

I have had the same problem and finally decided to do something about it. This was my quick solution and it has served me well. All I had was all thread at the time but I am going to by the right sized bolts to replaced the all thread and nut setup.

Basically what I did was drill and tap two holes in the top of the fixed jaw so I could bolt an aluminum extension to it. The extension has 2 holes drilled and tapped vertically with 2 bolts to clamp a small part down against the base of the saw. Has worked really good so far. It is easy to remove and install when needed.

Basically what I did was drill and tap two holes in the top of the fixed jaw so I could bolt an aluminum extension to it. The extension has 2 holes drilled and tapped vertically with 2 bolts to clamp a small part down against the base of the saw. Has worked really good so far. It is easy to remove and install when needed.

Re: Workholding Device for Horizontal Band Saw

I keep a 3/8-16 connector nut about an inch long with a bolt in it in the gutter of the old power hacksaw. It gets used to prop the outer edge of the moveable jaw when the stock doesn't reach far enough past the center. Handy - being adjustable.

There are also two T slots running the length vise which end in square holes where square head bolts (or nuts) can be inserted and used to hold the stock down. - Partially shown behind the blade.

BC

There are also two T slots running the length vise which end in square holes where square head bolts (or nuts) can be inserted and used to hold the stock down. - Partially shown behind the blade.

BC

BC

If there was only one way to do each machining job, the smell of sulphurized cutting oil smoke would have fewer fond memories.

If there was only one way to do each machining job, the smell of sulphurized cutting oil smoke would have fewer fond memories.

-

10 Wheeler Rob

- Posts: 1546

- Joined: Tue Mar 21, 2006 2:44 pm

- Location: East Hartford, CT

Re: Workholding Device for Horizontal Band Saw

I clamp small peices beween larger wood blocks that extend inot the horizontal band saw clamp jaaws all the time. good harder woods, and plywood strips work well. I often shim the other end of the wood blocks to be paralllel in the jaws. If it a really small peice of metal I will cut right througnh the wood and metal both.