How to transport a lathe

How to transport a lathe

Hello all,

A family friend has agreed to sell me his Meuser 00-L lathe. This is a real honor as this is the man who inspired me many years ago.

I do however, need some advice on how to move this. My questions to the folks who have done this are as follows:

a) Do I hire professional help to move it from his garage to my shop? It's about 500 miles from my house and over the Rocky Mountains. I'm not planning to make the adventure until spring but I need to make plans now so that we are ready when the time comes.

b) If I decide to tackle this with my sons (24 and 21) how is this done? How does one lift an 1100 Kg lathe onto a trailer? What are the safe lift points?

How does one strap the lathe down safely? I'm assuming you wrap the lathe in saran wrap or something similar for protection on the journey.

c) If you lift the lathe with a forklift does it need to be secured on a pallet?

It won't be a problem to rent a trailer and my pickup is more than capable. There is a crane service in the city where the lathe is located.

Am I an idiot for even considering the do it yourself option? Any and all advice would be greatly appreciated.

A family friend has agreed to sell me his Meuser 00-L lathe. This is a real honor as this is the man who inspired me many years ago.

I do however, need some advice on how to move this. My questions to the folks who have done this are as follows:

a) Do I hire professional help to move it from his garage to my shop? It's about 500 miles from my house and over the Rocky Mountains. I'm not planning to make the adventure until spring but I need to make plans now so that we are ready when the time comes.

b) If I decide to tackle this with my sons (24 and 21) how is this done? How does one lift an 1100 Kg lathe onto a trailer? What are the safe lift points?

How does one strap the lathe down safely? I'm assuming you wrap the lathe in saran wrap or something similar for protection on the journey.

c) If you lift the lathe with a forklift does it need to be secured on a pallet?

It won't be a problem to rent a trailer and my pickup is more than capable. There is a crane service in the city where the lathe is located.

Am I an idiot for even considering the do it yourself option? Any and all advice would be greatly appreciated.

-

Glenn Brooks

- Posts: 2930

- Joined: Mon Nov 10, 2014 1:39 pm

- Location: Woodinville, Washington

Re: How to transport a lathe

I just moved an 1800 pound lathe to my home shop. Your lathe is around 2400 pounds from the sound of it. So similar weight and bulk.

So you have two significant issues: how to load, and how to unload. Easiest way is to pick up the lathe with a fork lift - run straps around the bed, usually mid point of the lathe, and hoist with the straps. You don't want to lift from the bottom because of the high center of gravity. If you have a (large) fork lift available at your destination, lift with lifting straps and and drop it on to floor where you want toinstall and use it.

However, depending on how big your trailer is, a forklift might not be able to position the lathe over the axles properly, in which case you could use a 4 ton engine hoist to move the lathe around on your trailer, or an 8 ton pallet jack to move it. The engine hoist could lift the lathe with straps same as a forklift. The pallet jack needs to lift from the bottom. So I set the lathe on 4"x6" timbers and supported the timbers off the floor with 4 sets of 4"x4" placed at 90 degrees under the timbers, and aligned with the legs of the lathe stand. A pallet jack needs at least 3" clearance to get under the load, hence use 4x4's or two 2x4 doubled up to get clearance. Both pallet jack or possibly engine hoist, or forklift, can be rented from usually any local equipment rental company. The forklift was to Spendy for me ($400 including transport costs per day)' so I went with the pallet jack and lift gate (2500 pounds max lift capacity).

Be very careful with the trailer hitch and trailer you contemplate using. My local rental company would not rent a trailer to a vehicle that has less have an 800# hitch capacity. So for your lathe weight, you will probably need a trailer and hitch having 800# tounge capacity and minimum 5000pound load capacity, and some kind of trailer brakes.

And here is the big risk with a trailer. If you try to roll the lathe off a trailer with a pallet jack or similar, you will be going down a steep ramp, and risk tipping the lathe over. If it falls over, you will certainly break some of the components, maybe ruin the the major components. It has a very heavy and high center of gravity due to the table structure it sits on. Whatever you do, You will need to off load lathe by vertically sitting it on the ground.

I planned to use a car trailer that hydrolicly lowered the frame to the ground for load/offload, but couldn't reserve one the day I needed to move, so instead rented a 17' box van with hydrolic lift gate. This worked much better, using a pallet jacket to move the lathe off the truck. I loaded with a massive big forklift, used the pallet jack to push the lathe to the front of the box and tied it down with four 1200# ratcheting tie down straps during transport, and it didn't move an inch while underway.

Good luck on your move.

So you have two significant issues: how to load, and how to unload. Easiest way is to pick up the lathe with a fork lift - run straps around the bed, usually mid point of the lathe, and hoist with the straps. You don't want to lift from the bottom because of the high center of gravity. If you have a (large) fork lift available at your destination, lift with lifting straps and and drop it on to floor where you want toinstall and use it.

However, depending on how big your trailer is, a forklift might not be able to position the lathe over the axles properly, in which case you could use a 4 ton engine hoist to move the lathe around on your trailer, or an 8 ton pallet jack to move it. The engine hoist could lift the lathe with straps same as a forklift. The pallet jack needs to lift from the bottom. So I set the lathe on 4"x6" timbers and supported the timbers off the floor with 4 sets of 4"x4" placed at 90 degrees under the timbers, and aligned with the legs of the lathe stand. A pallet jack needs at least 3" clearance to get under the load, hence use 4x4's or two 2x4 doubled up to get clearance. Both pallet jack or possibly engine hoist, or forklift, can be rented from usually any local equipment rental company. The forklift was to Spendy for me ($400 including transport costs per day)' so I went with the pallet jack and lift gate (2500 pounds max lift capacity).

Be very careful with the trailer hitch and trailer you contemplate using. My local rental company would not rent a trailer to a vehicle that has less have an 800# hitch capacity. So for your lathe weight, you will probably need a trailer and hitch having 800# tounge capacity and minimum 5000pound load capacity, and some kind of trailer brakes.

And here is the big risk with a trailer. If you try to roll the lathe off a trailer with a pallet jack or similar, you will be going down a steep ramp, and risk tipping the lathe over. If it falls over, you will certainly break some of the components, maybe ruin the the major components. It has a very heavy and high center of gravity due to the table structure it sits on. Whatever you do, You will need to off load lathe by vertically sitting it on the ground.

I planned to use a car trailer that hydrolicly lowered the frame to the ground for load/offload, but couldn't reserve one the day I needed to move, so instead rented a 17' box van with hydrolic lift gate. This worked much better, using a pallet jacket to move the lathe off the truck. I loaded with a massive big forklift, used the pallet jack to push the lathe to the front of the box and tied it down with four 1200# ratcheting tie down straps during transport, and it didn't move an inch while underway.

Good luck on your move.

Moderator - Grand Scale Forum

Motive power : 1902 A.S.Campbell 4-4-0 American - 12 5/8" gauge, 1955 Ottaway 4-4-0 American 12" gauge

Ahaha, Retirement: the good life - drifting endlessly on a Sea of projects....

Motive power : 1902 A.S.Campbell 4-4-0 American - 12 5/8" gauge, 1955 Ottaway 4-4-0 American 12" gauge

Ahaha, Retirement: the good life - drifting endlessly on a Sea of projects....

Re: How to transport a lathe

As Jim Rozen pointed out:

The cost of having a professional do it for you is less than the cost of a visit to the emergency room.

I moved my 350 lb or so South Bend in my station wagon. This is NOT that move. You have some serious weight there. Mine could have broken bones; yours can disable worse.

However you do it, be safe.

Steve

The cost of having a professional do it for you is less than the cost of a visit to the emergency room.

I moved my 350 lb or so South Bend in my station wagon. This is NOT that move. You have some serious weight there. Mine could have broken bones; yours can disable worse.

However you do it, be safe.

Steve

Re: How to transport a lathe

Good advice from the other guys, I would add double emphasis on the high center of gravity...I know of at least 2 nice lathes that were buggered up bad from being dropped off a forklift. I have actually moved my 12"Craftsman lathe 3 times by myself w/o an accident, but it's not a load like yours...the last time was only about 300 ft. from the garage to my new shop, I picked it up with my 3-pt. hitch tractor boom & rigging straps. Main thing is to take it slow & careful & plan your moves, you should be OK...

Re: How to transport a lathe

I have moved my 4,500 lb 17 X 40 lathe 3 times, twice by myself without a forklift.

It's not easy but it can be done.

I used a car trailer, 2 machine roller skates, a floor jack, a 4,000 lb cherry picker and a bunch of 6 X 6 blocks and pieces of 2 X 4.

Along with a custom bracket I made to fit the ends of the lathe that I could hook the cherry picker into.

It's not easy but it can be done.

I used a car trailer, 2 machine roller skates, a floor jack, a 4,000 lb cherry picker and a bunch of 6 X 6 blocks and pieces of 2 X 4.

Along with a custom bracket I made to fit the ends of the lathe that I could hook the cherry picker into.

-

hammermill

- Posts: 2938

- Joined: Sun Jun 27, 2010 10:43 pm

- Location: pendleton or

Re: How to transport a lathe

in looking at the pics for this lathe the base can be chained to the trailer along with binders, the upper part I would use cloth ratchet straps to stabilize and keep the load in one place during a quick stop and to prevent tipping.

placing planking across the trailer bed to distribute load 2x6,s is also a good idea, some beds are not in as good of shape as they look.

I would sling load the lathe to remove any chance of tipping. buy good slings at Norco or oxarc. you will be using them during construction also.

do not try to use pure muscle as injurys are costly .

to unload rental of a large forklift is possible as may be reinforcing the shop trusses and installing temporary pillar posts to help support. then use a couple of chain hoists to pick it up and set it down after pulling the trailer out.

placing planking across the trailer bed to distribute load 2x6,s is also a good idea, some beds are not in as good of shape as they look.

I would sling load the lathe to remove any chance of tipping. buy good slings at Norco or oxarc. you will be using them during construction also.

do not try to use pure muscle as injurys are costly .

to unload rental of a large forklift is possible as may be reinforcing the shop trusses and installing temporary pillar posts to help support. then use a couple of chain hoists to pick it up and set it down after pulling the trailer out.

Re: How to transport a lathe

Wrapping straps around the bed is not a good idea as you can possibly bend the leadscrew and/or feed rod.EOsteam wrote:c) If you lift the lathe with a forklift does it need to be secured on a pallet?

Glenn

Operating machines is perfectly safe......until you forget how dangerous it really is!

Operating machines is perfectly safe......until you forget how dangerous it really is!

- SteveHGraham

- Posts: 7788

- Joined: Sat Jan 17, 2009 7:55 pm

- Location: Florida

Re: How to transport a lathe

When I sold my Clausing *spit* the guy who bought it brought a Jerr-Dan truck and pulled it up onto the bed.

Every hard-fried egg began life sunny-side up.

Re: How to transport a lathe

Thank you so much for the ideas!

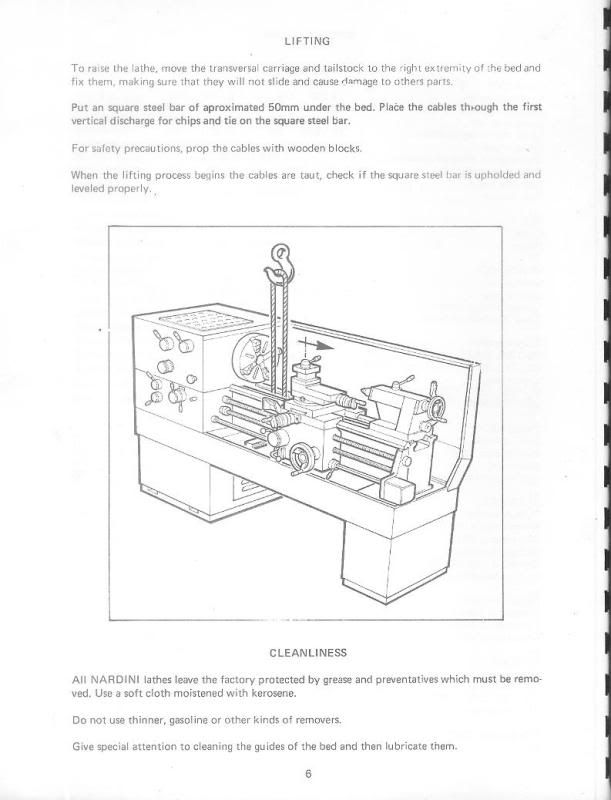

I think I'm leaning towards renting a sturdy double axle trailer here and having the crane company on the other end load it for me. The pickup is a 3/4 ton with conventional hitch and also a gooseneck option. It has an electric trailer brake controller. I'm feeling pretty confident that I can get it unloaded on this end safely with the straps and a sturdy rented forklift. With Glen's diagram of the Nardini lathe in mind, I think I'll try Meuser in Germany to see if there is a recommended lifting procedure.

I'll have to post some pics when she is nestled in the shop and happy in her new home.

One final question. Where would I look to see what the rough value of the lathe would be? It's going to come with a ton of tooling. It's listed as a 185 mm center height which is 7.28" (roughly 14.5" American swing) and pretty close to 40" bed length. Is there any formula or is it just what the two parties agree upon?

I think I'm leaning towards renting a sturdy double axle trailer here and having the crane company on the other end load it for me. The pickup is a 3/4 ton with conventional hitch and also a gooseneck option. It has an electric trailer brake controller. I'm feeling pretty confident that I can get it unloaded on this end safely with the straps and a sturdy rented forklift. With Glen's diagram of the Nardini lathe in mind, I think I'll try Meuser in Germany to see if there is a recommended lifting procedure.

I'll have to post some pics when she is nestled in the shop and happy in her new home.

One final question. Where would I look to see what the rough value of the lathe would be? It's going to come with a ton of tooling. It's listed as a 185 mm center height which is 7.28" (roughly 14.5" American swing) and pretty close to 40" bed length. Is there any formula or is it just what the two parties agree upon?

Re: How to transport a lathe

When I bought my mill, it was loaded at the site by an over head gantry, onto a car hauler type trailer. When I got it to my place I had a friend bring over his tow truck and he set it inside my garage by using the extending beam of winch.

I know yours is a lathe but I wonder if a tow truck my be able to lift it off for you cheaper than a crane.

It cost me 60 bucks to have mine off loaded.

Just a thought.

I know yours is a lathe but I wonder if a tow truck my be able to lift it off for you cheaper than a crane.

It cost me 60 bucks to have mine off loaded.

Just a thought.

Live for the moment!

Prepare for tomorrow!

Forgive the past!

Prepare for tomorrow!

Forgive the past!

-

Rob Gardner

- Posts: 463

- Joined: Sun Oct 23, 2005 9:27 am

- Location: Newbury, OH

Re: How to transport a lathe

EO, a few thoughts from an experienced novice (pun intended) as I have moved a Bridgeport mill and a 14" SOuthbend lathe 3 times now in less than 10 years! I looked up your Meuesr OO-L lathe. That's a large machine! Good for you! If I got the right information, it looks like it weighs about 2,200 lbs which is about what my Bridgeport mill weighs. In all instances I have used a 3/4 to 1 ton pickup truck with a Class 3 hitch and a tandem axle trailer.

When moving the lathe, there a few different ways to do it. The first time we moved the lathe, we mounted two 4x4 skids under the lathe, securing them to the base (assuming your machine has similar holes for leveling screws or attachment to crating or skids) with large lag screws. We used four (4) each 24" long sections of 1" black iron pipe to roll and steer the machine around and out of the shop (we turned one 90 degree turn with the pipe rollers) out to the trailer. We then simply winched it up on the bed of the trailer, removed the pipe rollers and strapped it down with 2 or 3 large ratcheting straps. You will want to make sure your trailer has a heavy duty enough frame rail to secure the come along to but if it doesn't have an angle iron railing, you could probably attach it to a chain looped around the tongue. Also, you will want a good heavy duty pry bar or if you know anyone who works for the railroad, get a good nipping spoon or lining bar which should have enough leverage to lift up one end of the machine at a time to get the pipe rollers out from underneath it.

The last time I moved it (just a couple months ago), I paid a local excavating contractor to bring his skidsteer and we lifted it under the ways with the forks spread apart to keep it stable and set it on the trailer. I was short on time during the week and opted for the quicker machine option. Most skidsteers will fit inside a standard garage door. My buddy just had to remove his gumball rotating beacon from the roof to fit inside. I was blessed with this last move of finding a house with the garage at basement level, so we set the lathe in line with the door on two 2x6x8 skids and rolled it with the rollers right inside the basement and into position.

Well, that's enough rambling for one post. Hope you post pics of the move so we can all learn something new from your upcoming adventure!! Lastly, what do you mean you're not going to move this lathe over the Rockies in the dead of winter?!?!? That would just make it a bigger challenge for me!!

Rob

When moving the lathe, there a few different ways to do it. The first time we moved the lathe, we mounted two 4x4 skids under the lathe, securing them to the base (assuming your machine has similar holes for leveling screws or attachment to crating or skids) with large lag screws. We used four (4) each 24" long sections of 1" black iron pipe to roll and steer the machine around and out of the shop (we turned one 90 degree turn with the pipe rollers) out to the trailer. We then simply winched it up on the bed of the trailer, removed the pipe rollers and strapped it down with 2 or 3 large ratcheting straps. You will want to make sure your trailer has a heavy duty enough frame rail to secure the come along to but if it doesn't have an angle iron railing, you could probably attach it to a chain looped around the tongue. Also, you will want a good heavy duty pry bar or if you know anyone who works for the railroad, get a good nipping spoon or lining bar which should have enough leverage to lift up one end of the machine at a time to get the pipe rollers out from underneath it.

The last time I moved it (just a couple months ago), I paid a local excavating contractor to bring his skidsteer and we lifted it under the ways with the forks spread apart to keep it stable and set it on the trailer. I was short on time during the week and opted for the quicker machine option. Most skidsteers will fit inside a standard garage door. My buddy just had to remove his gumball rotating beacon from the roof to fit inside. I was blessed with this last move of finding a house with the garage at basement level, so we set the lathe in line with the door on two 2x6x8 skids and rolled it with the rollers right inside the basement and into position.

Well, that's enough rambling for one post. Hope you post pics of the move so we can all learn something new from your upcoming adventure!! Lastly, what do you mean you're not going to move this lathe over the Rockies in the dead of winter?!?!? That would just make it a bigger challenge for me!!

Rob

-

Downwindtracker2

- Posts: 276

- Joined: Wed Feb 13, 2008 9:34 pm

- Location: B.C.

Re: How to transport a lathe

Pulling a trailer on ice can be hard on the underwear. Bring spares. Having said that, we are planning to go to Quartsite in January ,pulling a travel trailer. May drive down the coast.

A man of foolish pursuits, '91 BusyBee DF1224g lathe,'01 Advance RF-45 mill/drill,'68 Delta Toolmaker surface grinder,Miller250 mig,'83 8" Baldor grinder, plus sawdustmakers