Best Way to Center Strange Part in Lathe?

Re: Best Way to Center Strange Part in Lathe?

Could you make two plugs with center holes and run it between centers? Then you could finish up as Glenn suggests.

- SteveHGraham

- Posts: 7788

- Joined: Sat Jan 17, 2009 7:55 pm

- Location: Florida

Re: Best Way to Center Strange Part in Lathe?

The part is square, and the jaws are fine. The part is able to shift in the jaws because it is not in contact with a reference surface perpendicular to the axis of the lathe. That allows it to move so it's not parallel to the axis.

Starting with round bar would have worked, but I would have needed about 5" of bar over 3.5" in diameter.

Chris, it sounds like you did pretty much what I'm doing.

Starting with round bar would have worked, but I would have needed about 5" of bar over 3.5" in diameter.

Chris, it sounds like you did pretty much what I'm doing.

Every hard-fried egg began life sunny-side up.

Re: Best Way to Center Strange Part in Lathe?

Unless you took the required time to adjust the travel so it is dead parallel with the ways of the machine, that's not an acceptable method to indicate the piece true. You should rely on the carriage, not the compound, as any error in alignment in the compound would be introduced to the part. A very frustrating way to get the part running as desired.SteveHGraham wrote: I used the compound rest to move the dial indicator up and down the part.

Harold

Wise people talk because they have something to say. Fools talk because they have to say something.

- SteveHGraham

- Posts: 7788

- Joined: Sat Jan 17, 2009 7:55 pm

- Location: Florida

Re: Best Way to Center Strange Part in Lathe?

Even for height?

Well, I suppose it would be off, unless I was positive the face I was indicating was level with the lathe bed in the x direction. But I wouldn't expect a significant error if the indicator tip was only moving +x or -x a millimeter or so.

Well, I suppose it would be off, unless I was positive the face I was indicating was level with the lathe bed in the x direction. But I wouldn't expect a significant error if the indicator tip was only moving +x or -x a millimeter or so.

Every hard-fried egg began life sunny-side up.

Re: Best Way to Center Strange Part in Lathe?

It's possible that for height* that would be acceptable, but I can't imagine anyone wishing to crank a compound endlessly when the same move can be accomplished with the carriage in far less time and almost no effort.SteveHGraham wrote:Even for height?

*The problem, even for height, would be exaggerated if there is error in alignment of the compound and the part isn't dead perpendicular (the top surface must be level). You'd have no clue if the part was not straight, or if the indicator was on a surface with a slight angle. Of course, using the cross slide, you could run the indicator across the top surface each time it's moved, to re-establish level, but that's just more time added to the job when it isn't necessary. Personally, I'd stick with the carriage. It should traverse the part in both axes without error.

In a pinch, under some strange circumstance, sure, I'd use the compound, too, but it wouldn't be my first choice.

When you face a task like this, start at the jaws, establishing the offset desired, then straighten the piece, followed by checking the offset to see if it is correct. It usually takes more than one iteration to establish proper location and attitude, but, if you work carefully, once you've established parallelism, the part can often be moved slightly without losing orientation.

Harold

Wise people talk because they have something to say. Fools talk because they have to say something.

Re: Best Way to Center Strange Part in Lathe?

This is about the way I would do it. I would simply indicate at the jaws first, the the far end.GlennW wrote:Plug in the tailstock center and then "level" the part in Z using an indicator riding on the carriage. Adjust one air of opposing jaws, (not gripping the part tightly) rotate the chuck 90 degrees, then the other pair. Probably take a couple of iterations.

That'll get you closer than what you are doing now.

The first prerequisite is that your tail stock is centered, if it is to be used. Does the hole go all the way through? Maybe you could just mount it on centers and turn it.

If not, you have three sides where the hole is equidistant. Can we assume the hole is drilled parallel to the sides? If so, I would start with the piece as you have it with a dead center in the TS pressing the part against the parallels. Indicate the two opposing sides that are to be equidistant right next to the jaws, and make them even there. Then I would go to the third equidistant side and move the part (jaws) to the same dial reading as the others. Repeat the three sides right at the jaws to make them all equal. If your TS is centered and the hole is truly parallel to the sides, then when you traverse the long sides, they should be parallel to the ways.. If not, then your hole might not be parallel to the sides (or the TS off center). If you still need to bore the hole, you can remove the tail stock and bump the end, indicating the sides to bring them in. After that, you'll have to repeat the readings at the jaws, then far end again.

BTW, I suspect you've already moved on? And I did not notice page two, so Harold's last sentence basically said it more succinctly...

Standards are so important that everyone must have their own...

To measure is to know - Lord Kelvin

Disclaimer: I'm just a guy with a few machines...

To measure is to know - Lord Kelvin

Disclaimer: I'm just a guy with a few machines...

Re: Best Way to Center Strange Part in Lathe?

Would not be that big of a task to fabricate a driver for the "square" end. Some scrap steel, a cut-off wheel, a welder, three long bolts and some nuts. One of the bolts is the driver. Scrap it when you're done, just like the rest of the rig. No more futzing about trying to keep the thing from moving in the chuck.

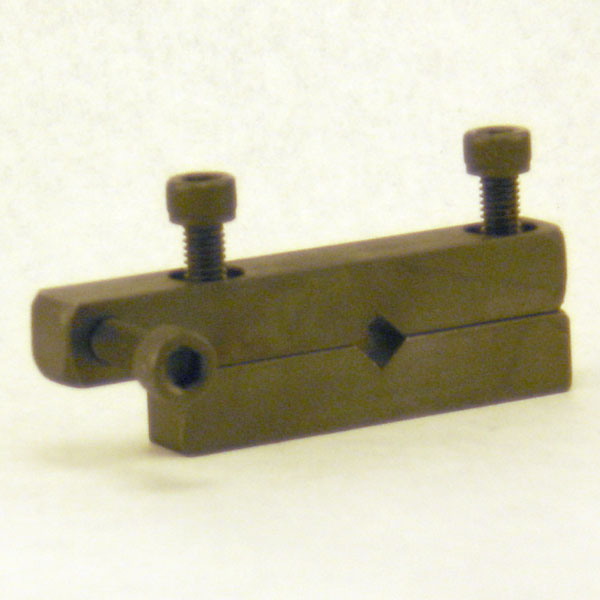

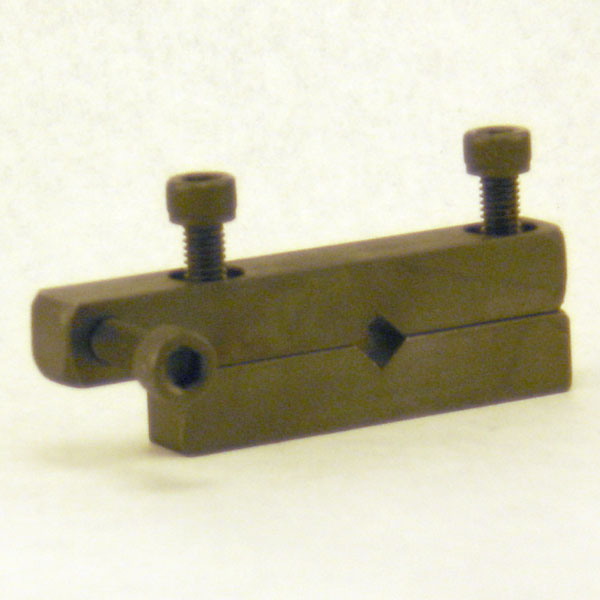

Edit, a smaller version of what I'm thinking, only no welding.

Edit, a smaller version of what I'm thinking, only no welding.

Last edited by rudd on Tue Nov 10, 2015 8:56 pm, edited 1 time in total.

Re: Best Way to Center Strange Part in Lathe?

Here's a strange way for a strange part. At least one side of the rectangle can be measured, scribed and a center punched. At least some collet fits the lathe spindle bore and can be tightened from the left of headstock ( tube or drawbar ). The collet holds a dead center (straight shaft with 60* end). The collet is tightened when the center locates the part at the depth into the required depth into the chuck. The chuck is adjusted /tightened to present required center at tail end. The whole time, the center in the spindle is locating the left side. Drilling and boring can continue towards the head until the collet is loosened and center is slid back into the collet and retightened.

Re: Best Way to Center Strange Part in Lathe?

I hadn't looked at the pics right before that post, so...maybe something to think about.