Parting with internal thread

- Blackwatch42nd

- Posts: 6

- Joined: Sat Jun 18, 2016 12:33 pm

- Location: Blanco, TX

Parting with internal thread

Hi,

New here and to machining. Hoping for some help with a small project.

I'm trying to part a brass rod that has been bored and internally threaded. Unfortunately, when the part separates, it does so leaving some of the thread attached from the parting tool width. I know why it's happening, just trying to find a work around. Any thoughts greatly appreciated.

John OD: 1"

ID 3/4"

New here and to machining. Hoping for some help with a small project.

I'm trying to part a brass rod that has been bored and internally threaded. Unfortunately, when the part separates, it does so leaving some of the thread attached from the parting tool width. I know why it's happening, just trying to find a work around. Any thoughts greatly appreciated.

John OD: 1"

ID 3/4"

-

John Hasler

- Posts: 1852

- Joined: Tue Dec 06, 2016 4:05 pm

- Location: Elmwood, Wisconsin

Re: Parting with internal thread

Screw a sacrificial mandrel into it and part right into that.

-

johnfreese

- Posts: 219

- Joined: Thu Jan 21, 2016 2:10 am

Re: Parting with internal thread

Bore an internal groove at the cut location before parting off.

Re: Parting with internal thread

It is generally desirable that the thread receive a chamfer after parting. If the task was mine, I'd use soft jaws, bored to hold the piece not only on center, but perpendicular, then I'd take a miniscule facing cut, followed by the chamfer, inside and outside, all of which would be done with the same tool. Done! And no damage to the knurl. Using soft jaws as I suggested provides the perfect stop, so you can control length to a high degree of precision, all without effort.

Harold

Harold

Wise people talk because they have something to say. Fools talk because they have to say something.

- Blackwatch42nd

- Posts: 6

- Joined: Sat Jun 18, 2016 12:33 pm

- Location: Blanco, TX

Re: Parting with internal thread

Thanx to all for the quick reply.

JohnH: My latest thoughts were along yours. But I'm thinking a sacrificial all thread rod. I could thread it in to the piece, center drill it and use a live center to support the whole business.

JohnF: I would have to get the grove at the exact spot of the leading edge of the parting grove, which is possible. I'll have to think on that one.

HaroldH: Still real new at this and not sure of the setup for your idea. What are "soft jaws"? Are they made or acquired?

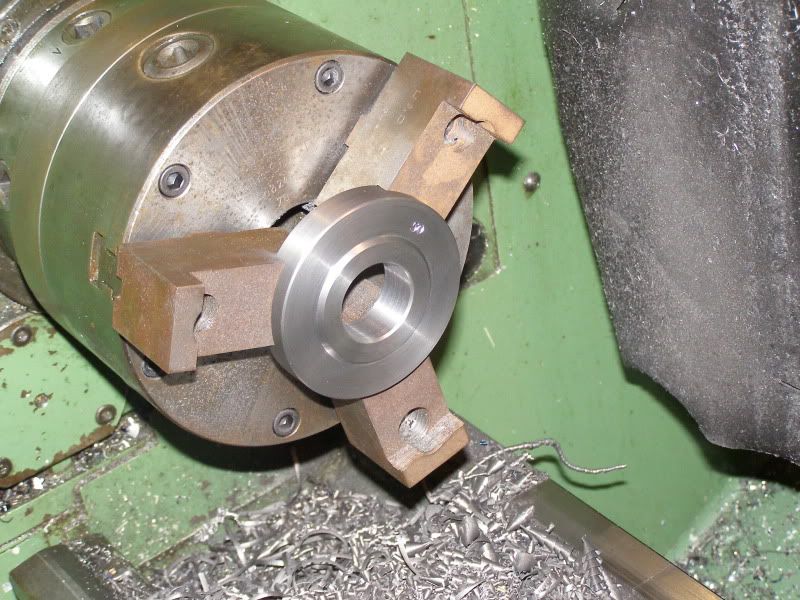

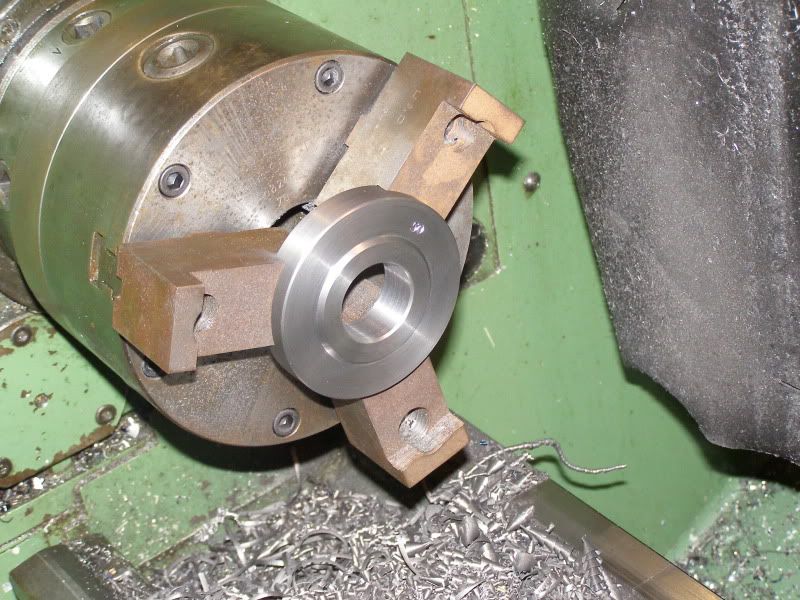

Here's what the part looks like before parting Thanx again

John

JohnH: My latest thoughts were along yours. But I'm thinking a sacrificial all thread rod. I could thread it in to the piece, center drill it and use a live center to support the whole business.

JohnF: I would have to get the grove at the exact spot of the leading edge of the parting grove, which is possible. I'll have to think on that one.

HaroldH: Still real new at this and not sure of the setup for your idea. What are "soft jaws"? Are they made or acquired?

Here's what the part looks like before parting Thanx again

John

Re: Parting with internal thread

Here's what Harold is referring to.

The jaws are soft steel (they can also be aluminum) and you bore for the needed diameter down to a depth that holds the part flat.

If you don't have jaws that bolt on, you can always make these:

If you do have bolt on jaws, I have several sets of soft jaws for sale:

http://www.chaski.org/homemachinist/vie ... =soft+jaws

Steve

The jaws are soft steel (they can also be aluminum) and you bore for the needed diameter down to a depth that holds the part flat.

If you don't have jaws that bolt on, you can always make these:

If you do have bolt on jaws, I have several sets of soft jaws for sale:

http://www.chaski.org/homemachinist/vie ... =soft+jaws

Steve

-

John Hasler

- Posts: 1852

- Joined: Tue Dec 06, 2016 4:05 pm

- Location: Elmwood, Wisconsin

Re: Parting with internal thread

That's what I meant.Blackwatch42nd wrote:Thanx to all for the quick reply.

JohnH: My latest thoughts were along yours. But I'm thinking a sacrificial all thread rod. I could thread it in to the piece, center drill it and use a live center to support the whole business.

John

Re: Parting with internal thread

When the parting tool breaks through the brass part it may grab it and tighten it on the threaded rod pinching the parting tool.

That wouldn't have a happy ending.

That wouldn't have a happy ending.

Glenn

Operating machines is perfectly safe......until you forget how dangerous it really is!

Operating machines is perfectly safe......until you forget how dangerous it really is!

Re: Parting with internal thread

What Glenn said. I can think of no faster and better way to break a thin parting tool (keeping in mind, I hand grind parting tools from square stock, I do not use commercial parting tools).

While using a sacrificial mandrel (threaded) can be a solution, it's not a good one, nor does it allow for the critical operation of chamfering the thread. Soft jaws, or a step collet, are the answer. Either permits "fine tuning" to resulting part, while other methods do not.

Harold

Edit:

Want to learn more about soft jaws, the "magic bullet" of lathe work? Follow this link: http://www.chaski.org/homemachinist/vie ... =44&t=4266

While using a sacrificial mandrel (threaded) can be a solution, it's not a good one, nor does it allow for the critical operation of chamfering the thread. Soft jaws, or a step collet, are the answer. Either permits "fine tuning" to resulting part, while other methods do not.

Harold

Edit:

Want to learn more about soft jaws, the "magic bullet" of lathe work? Follow this link: http://www.chaski.org/homemachinist/vie ... =44&t=4266

Wise people talk because they have something to say. Fools talk because they have to say something.

-

Russ Hanscom

- Posts: 1955

- Joined: Wed Mar 15, 2006 11:10 pm

- Location: Farmington, NM

Re: Parting with internal thread

A parting tool with a angled end, instead of square might reduce amount of tear out. Since you are going to have to face and chamfer anyway...

-

John Hasler

- Posts: 1852

- Joined: Tue Dec 06, 2016 4:05 pm

- Location: Elmwood, Wisconsin

Re: Parting with internal thread

I see no reason to expect that with a short, fat, stiff parting tool, which he can use here since the cut is wide and shallow.GlennW wrote:When the parting tool breaks through the brass part it may grab it and tighten it on the threaded rod pinching the parting tool.

That wouldn't have a happy ending.

Perhaps use aluminum of maybe even plastic for the threaded rod..

-

johnfreese

- Posts: 219

- Joined: Thu Jan 21, 2016 2:10 am

Re: Parting with internal thread

If you use a properly shaped boring tool to groove the ID before parting it can do the chamfers and eliminate the need for a second op.