Enco 12x36 Bench Lathe

-

rbertalotto

- Posts: 71

- Joined: Sat Aug 16, 2008 11:38 am

- Location: Dartmouth, MA

Re: Enco 12x36 Bench Lathe

Great thread...The stand should be painted white.............Red / White / Blue.......True Texas!

Re: Enco 12x36 Bench Lathe

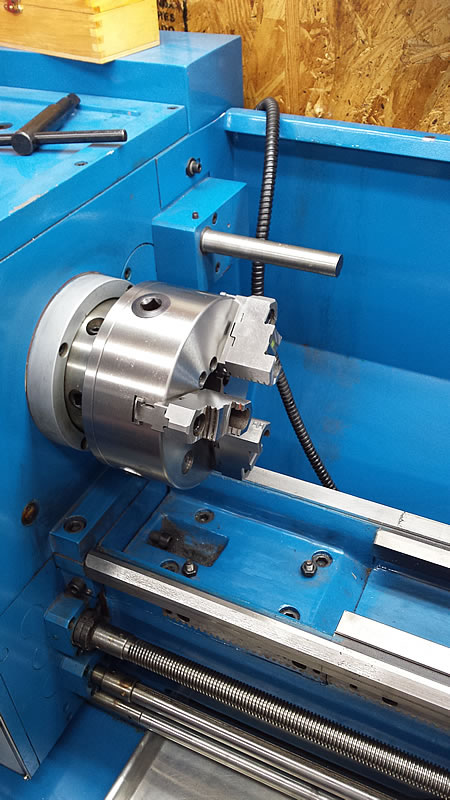

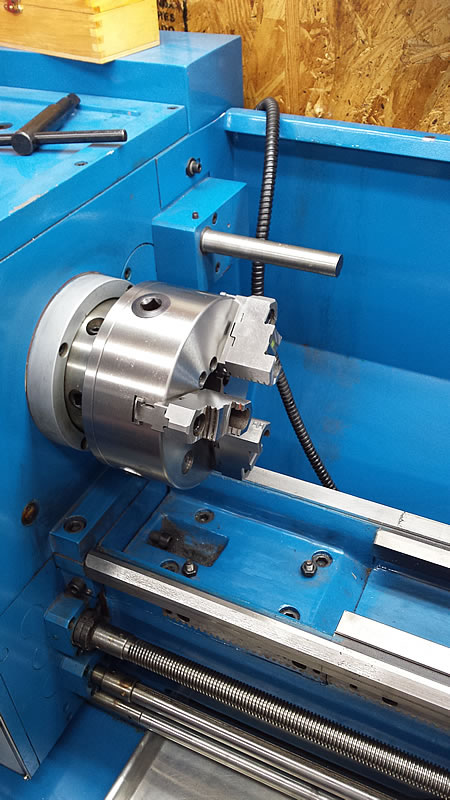

Hadn't done much lately with this - but I did get tired of trying to dial in a chuck that would not dial. The jaws need grinding and I don't have a mount for a Dremel or the time right now to make one. 20% off and free shipping bought a 6" direct mount "Interstate". It runs right at .002 TIR and that's pretty good I think. If I need better I have the 8" 4 jaw direct mount.

At the bottom is my new "chip pan" - turns out a baker's half sheet pan fits under there like it was made for it. Now I owe the kitchen a half sheet baking pan.

At the bottom is my new "chip pan" - turns out a baker's half sheet pan fits under there like it was made for it. Now I owe the kitchen a half sheet baking pan.

Chris -

http://raceabilene.com/kelly/hotrod

"Check all parts for proper condition before operation; if normal safety precautions are noticed carefully, this machine can provide you withstanding of accurate service."

http://raceabilene.com/kelly/hotrod

"Check all parts for proper condition before operation; if normal safety precautions are noticed carefully, this machine can provide you withstanding of accurate service."

Re: Enco 12x36 Bench Lathe

I see the chuck has master jaws. A great choice, as you can now use soft jaws.

Harold

Harold

Wise people talk because they have something to say. Fools talk because they have to say something.

Re: Enco 12x36 Bench Lathe

I hadn't thought of soft jaws (amateur LOL) but I did think the two piece jaws would have several benefits. I think I did OK for just under $200.

Q - are the master jaws made to some sort of standard dimension that allows other mfg outer jaws to be fitted?

Q - are the master jaws made to some sort of standard dimension that allows other mfg outer jaws to be fitted?

Chris -

http://raceabilene.com/kelly/hotrod

"Check all parts for proper condition before operation; if normal safety precautions are noticed carefully, this machine can provide you withstanding of accurate service."

http://raceabilene.com/kelly/hotrod

"Check all parts for proper condition before operation; if normal safety precautions are noticed carefully, this machine can provide you withstanding of accurate service."

Re: Enco 12x36 Bench Lathe

Most we run across here will be American Standard tongue and groove. However, there are others, but mostly found in the CNC world.

Russ

Master Floor Sweeper

Master Floor Sweeper

Re: Enco 12x36 Bench Lathe

I am unaware of any standards in regards to jaw tops, although I suspect there may be some, at least with some manufacturers.Falcon67 wrote:I hadn't thought of soft jaws (amateur LOL) but I did think the two piece jaws would have several benefits. I think I did OK for just under $200.

Q - are the master jaws made to some sort of standard dimension that allows other mfg outer jaws to be fitted?

Soft jaws are quite easy to make, and are a great project, assuming you enjoy making things. Some guys prefer to buy anything that can be purchased, as time, to them, is far more important.

Soft jaws can be made from either mild steel or aluminum, both of which work well. Aluminum jaws tend to be limited in life due to the stock remaining on the jaws, while steel jaws can easily have new segments welded on them, so their useful life is almost limitless.

Getting back to the jaws, and welding---it's not a good idea to weld new material on aluminum jaws unless you have the ability to restore the artificially aged condition. Welding renders them dead soft, which isn't a great condition as they are all too easily deformed.

In order to restore the aged condition (hardening), they must first be solution annealed. Not a difficult thing to do, but one should have a heat treat oven in order to prevent over heating (very close to the melting temperature), and a proper soak time. It's just way easier to just toss old aluminum jaws once they're consumed.

If you make jaws, just match the dimensions of the mating surfaces of the top jaws. I like to number them, so when they're re-installed they run as closely as they can. That way a minimum amount is removed for new settings. Also, consider how they'll be used. You may wish to make extra long jaws, or extra tall jaws---as that increases usefulness and lifespan. You can also make them wide (pie jaws) so you don't distort delicate items.

All in all, soft jaws are the magic bullet for work holding.

Harold

Wise people talk because they have something to say. Fools talk because they have to say something.

Re: Enco 12x36 Bench Lathe

All of mine have matched the "American Standard". So far that includes a couple of Pratt Burnerds, a Bison, and a no-name Chinese chuck. You can also buy pre-made soft jaws to fit this standard. I stumbled across some nice commercially produced soft jaws for my current 8" Bison on ebay that I got for (IIRC) around $16 shipped. Apparently he had multiple sets fed onto ebay one set at a time, because the next set appeared with a buy it now for around $40 + shipping (or something like that, a lot more than I paid anyway).

There is another I've seen and can't recall the name now, but seems like most of the automatic CNC chucks use it. Looks kinda like the interface on hold down step blocks.

I'm sure there are others, but those are what I've encountered.

There is another I've seen and can't recall the name now, but seems like most of the automatic CNC chucks use it. Looks kinda like the interface on hold down step blocks.

I'm sure there are others, but those are what I've encountered.

Russ

Master Floor Sweeper

Master Floor Sweeper

Re: Enco 12x36 Bench Lathe

Interesting. The chuck for my Graziano (came with the lathe, from Italy) doesn't share a configuration with anything I've seen, although it is similar. There's what looks like a modified Woodruff key that inserts in the center of the master jaw, with the flat portion fitting within a slot in the soft jaw. This keyway is located midway between the two mounting screws. The jaws also are slotted, so they key on the width of the master jaw. A good system, but different from others I've seen.BadDog wrote:All of mine have matched the "American Standard". So far that includes a couple of Pratt Burnerds, a Bison, and a no-name Chinese chuck. There is another I've seen and can't recall the name now, but seems like most of the automatic CNC chucks use it. Looks kinda like the interface on hold down step blocks.

I'm sure there are others, but those are what I've encountered.

Harold

Wise people talk because they have something to say. Fools talk because they have to say something.

Re: Enco 12x36 Bench Lathe

I did look around and from what I saw it'd be cheaper and more fun to buy stock and make your own. Good practice on milling.

Chris -

http://raceabilene.com/kelly/hotrod

"Check all parts for proper condition before operation; if normal safety precautions are noticed carefully, this machine can provide you withstanding of accurate service."

http://raceabilene.com/kelly/hotrod

"Check all parts for proper condition before operation; if normal safety precautions are noticed carefully, this machine can provide you withstanding of accurate service."

Re: Enco 12x36 Bench Lathe

I've made a number of sets, mostly from low carbon steel. But with the cost of aluminum, and ready to go for less than $20 in my hand, I'll buy them...

Russ

Master Floor Sweeper

Master Floor Sweeper