Benchmaster Restoration

Benchmaster Restoration

How's it going everyone? I have my first mill, I found a used Benchmaster not far from where I live. It's a bit small, but it will be enough for the work I am trying to do- for the most part.

I would like to restore it, any advice? Who sells a good motor for this kind of mill? Has anyone had any luck with DROs on these mills?

When it comes time to build the workshop, is it a bad idea even with the smaller machines to put multiple machines on one bench? Or should I have separate stands for each machine (except the drill press and grinder- that would be sort of frivolous) to rest on? As far as the lathe goes, I was looking for something compact like a Southbend 9 inch swing or equivalent.

Thanks everyone!

I would like to restore it, any advice? Who sells a good motor for this kind of mill? Has anyone had any luck with DROs on these mills?

When it comes time to build the workshop, is it a bad idea even with the smaller machines to put multiple machines on one bench? Or should I have separate stands for each machine (except the drill press and grinder- that would be sort of frivolous) to rest on? As far as the lathe goes, I was looking for something compact like a Southbend 9 inch swing or equivalent.

Thanks everyone!

Re: Benchmaster Restoration

I have a Benchmaster mill, it has a 1/2 hp motor which is enough power for me. I can't help with DRO but it sounds interesting.

John

John

Re: Benchmaster Restoration

Pratt & Whitney used to sell a bench for the mill, lathe and the sensitive drill:

Build it sturdy, and you should be fine.

Steve

Build it sturdy, and you should be fine.

Steve

Re: Benchmaster Restoration

If I could rig something like that up, I think I would have the coolest looking shop for sure.SteveM wrote:Pratt & Whitney used to sell a bench for the mill, lathe and the sensitive drill:

Build it sturdy, and you should be fine.

Steve

I'm starting to think that something that has wheels on the bottom would be nice, chances are excellent I will be moving.

Re: Benchmaster Restoration

I would stay away from wheels. You want something rock solid, not something that is going to be moving around on you. You can make a dolly for it when you need to move it.Weibel wrote:I'm starting to think that something that has wheels on the bottom would be nice, chances are excellent I will be moving.

Steve

Re: Benchmaster Restoration

I have put wheels under the heavy stuff and then blocked up the whole lot so the wheels don't touch. It is then relatively simple to pick up the stuff with a floor jack, remove the blocking and wheel the equipment to another location. All my heavy stuff except for the Toolmaker Grinder has suspended wheels. Accuracy may suffer, but no one will notice given my abilities. make sure your wheels are load rated for the equipment. (equipment weight/2 = wheel rating)

--earlgo

--earlgo

Before you do anything, you must do something else first. - Washington's principle.

Re: Benchmaster Restoration

I'm rebuilding my BenchMaster MV1 as it was too worn when I got it to do the work I want. But when done it will go on

a 'cart/cabinet' that will include drawers for all the acoutrements as well as a chip shield around three sides. It will be

on casters BUT when being used it will be on blocks just a bit taller than the casters. My small space seems to change

arrangements now and again so casters are under, or will be under, most everything.

Pete

a 'cart/cabinet' that will include drawers for all the acoutrements as well as a chip shield around three sides. It will be

on casters BUT when being used it will be on blocks just a bit taller than the casters. My small space seems to change

arrangements now and again so casters are under, or will be under, most everything.

Pete

Just tryin'

Re: Benchmaster Restoration

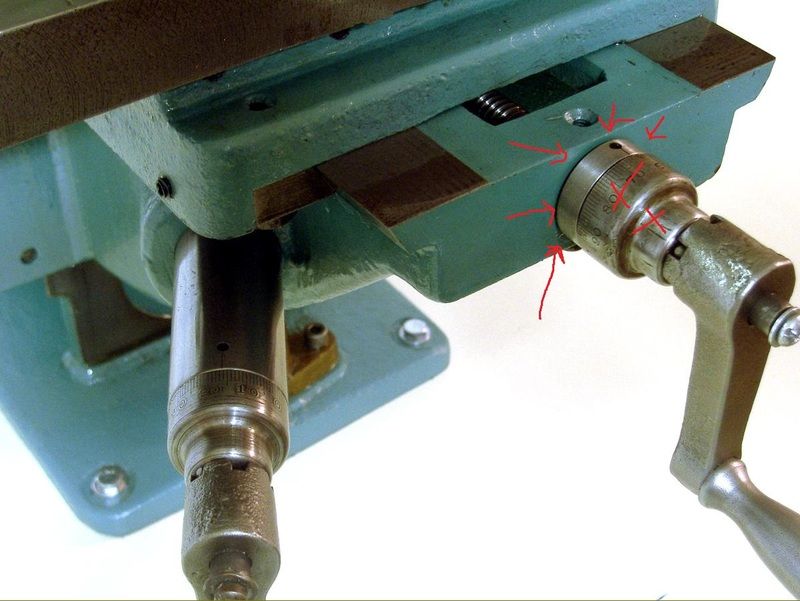

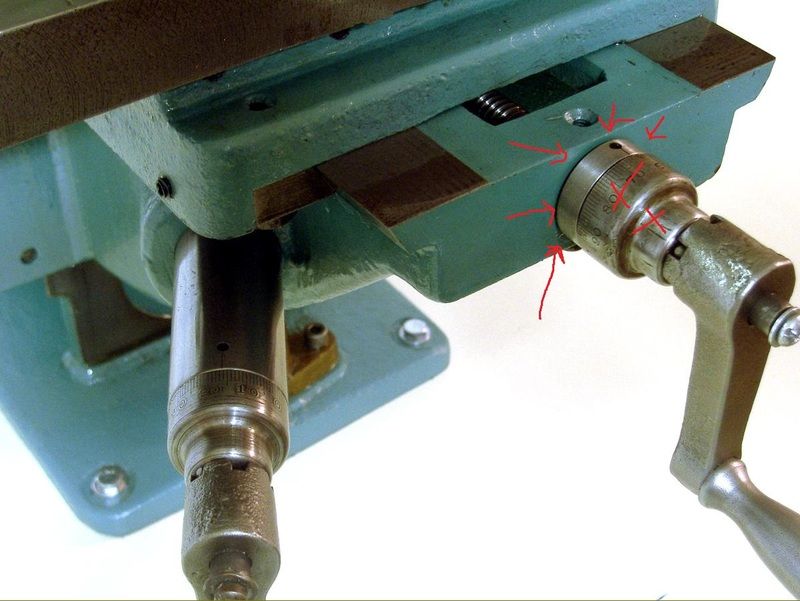

I have hit a serious SNAFU.

How the hell do I remove that ring?! There are two rings on these Duro versions, one on the inside of the measuring ring (which is why I put two Xs on it) and then the one on the outside. There was NO Allen screw in there or anything!

Any ideas?

How the hell do I remove that ring?! There are two rings on these Duro versions, one on the inside of the measuring ring (which is why I put two Xs on it) and then the one on the outside. There was NO Allen screw in there or anything!

Any ideas?

Re: Benchmaster Restoration

The "measuring ring"/ feed dial is likely keyed to the shaft. With the handle and any nut behind it removed, it should slide off. You may be able to see the key or slot. Sometimes a shaft is tapered or stepped and still has a Woodruff key but the shaft at a smaller diameter as seen from the outside has no slot. It has to be keyed.

Re: Benchmaster Restoration

Hi There,

I haven't owned or worked on a Bench Master myself but the collar

behind the graduated dial is very similar to other machines out there.

The collar is threaded into the casting and the hole in the periphery

is for a "pin spanner wrench" which will allow you to turn the collar.

South Bend Lathes used a similar system for their lathes cross slide

and compound screws.

Good Luck!

-Blue Chips-

Webb

I haven't owned or worked on a Bench Master myself but the collar

behind the graduated dial is very similar to other machines out there.

The collar is threaded into the casting and the hole in the periphery

is for a "pin spanner wrench" which will allow you to turn the collar.

South Bend Lathes used a similar system for their lathes cross slide

and compound screws.

Good Luck!

-Blue Chips-

Webb

Re: Benchmaster Restoration

On my BenchMaster that ring is threaded onto the leadscrew and acts as one side of the thrust bearing. Mine has a set screw

with a brass shoe in the hole to bear against the thread. Look very closely around the ring to see if there is a taper pin

holding yours on. With time and wear they can be very hard to see.

Pete

with a brass shoe in the hole to bear against the thread. Look very closely around the ring to see if there is a taper pin

holding yours on. With time and wear they can be very hard to see.

Pete

Just tryin'

Re: Benchmaster Restoration

How on earth do I remove this thing? I didn't see a set screw in there at all.