tube / bar for Bridgeport M head mounting

Re: tube / bar for Bridgeport M head mounting

One thing I have found is that there are more options available in 3" tube than 3-1/4".

I could get a 3" pipe and some 3-1/4" OD tube with 1/8" wall, slice off a piece and split it to act as a bushing. Any inconsistencies in the spacer thickness are likely to have a negligible impact on the concentricity of the ram, particularly if I have all three spacers split in the same place and put the splits all facing the same direction.

Steve

I could get a 3" pipe and some 3-1/4" OD tube with 1/8" wall, slice off a piece and split it to act as a bushing. Any inconsistencies in the spacer thickness are likely to have a negligible impact on the concentricity of the ram, particularly if I have all three spacers split in the same place and put the splits all facing the same direction.

Steve

Re: tube / bar for Bridgeport M head mounting

Steve

I have been following this thread but I'm not of perfect understanding re: the particulars.

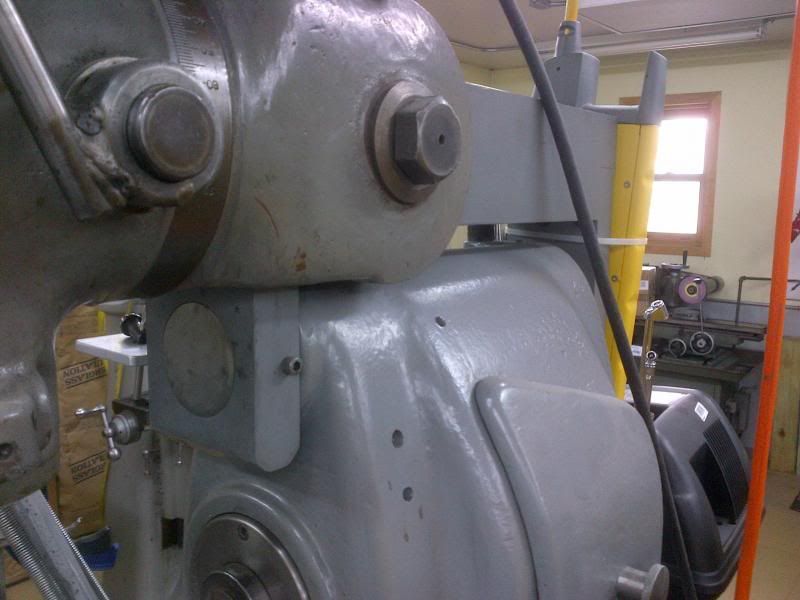

You are mounting the BP head to the overarms on a horizontal, I think. The head, pictured, has tilt but no nod.

Does your mount provide nod?

What diameter are the o/a holes on the horizontal? 3.250? Is there only one, or two?

How much extension will the tube(s) or pipe(s) see?

Do you have room on the back end for balance?

Since the head has no quill, you will use the knee for Z?

Thanks for your patience.

I have been following this thread but I'm not of perfect understanding re: the particulars.

You are mounting the BP head to the overarms on a horizontal, I think. The head, pictured, has tilt but no nod.

Does your mount provide nod?

What diameter are the o/a holes on the horizontal? 3.250? Is there only one, or two?

How much extension will the tube(s) or pipe(s) see?

Do you have room on the back end for balance?

Since the head has no quill, you will use the knee for Z?

Thanks for your patience.

Re: tube / bar for Bridgeport M head mounting

Yes, mounting the Bridgeport using the overarm mount.Carm wrote: I have been following this thread but I'm not of perfect understanding re: the particulars.

You are mounting the BP head to the overarms on a horizontal, I think. The head, pictured, has tilt but no nod.

The overarm is the type with the piece to hold the arbor integral to the end. I can flip it around to mount the head, but that limits how far out it can go (although it likely will be enough), and I have to have about three feet of room behind the machine to get it on/off. The room behind the machine may be the bigger issue. It will depend on where it ends up. I'm completely re-arranging the shop for some new machines coming in.

The mount I have is the same as shown in the attached picture. I can mount the head on the very end of the overarm, but there would be no nod, or it can mount on on the side, in which case I would have nod. Tilt left-right would just be with the overarm (have to be careful to not let it fall).Carm wrote: Does your mount provide nod?

There are two, front and back. The holes are 3.25"Carm wrote: What diameter are the o/a holes on the horizontal? 3.250? Is there only one, or two?

Not sure yet. I don't have the knee and table on right now (still cleaning out the shop so I can set it up). My guess is about 6" to a foot if I have the head on the end. Probably 18" max.Carm wrote: How much extension will the tube(s) or pipe(s) see?

Are you thinking I might need a counterweight? It's possible, but the mill weights 1,300 lbs, so I'm not sure it will need it.Carm wrote: Do you have room on the back end for balance?

The head pictured is what Spro has. Mine is an M head and I do have quill travel.Carm wrote: Since the head has no quill, you will use the knee for Z?

Steve

Re: tube / bar for Bridgeport M head mounting

Thanks for the info. Throwing out some ideas.

I asked about balance not out of concern for tipping but ease of extension and some other concern that is in the back of my mind but can't articulate yet.

You could cut your existing o/a and machine spigot/socket to reassemble (sacrilege!)

You could make a plug(s) that fit the o/a holes that adapt round to rectangular section tube (available in lots of WT's), your o/a would be max. 3" deep.

If the knee isn't critical for Z you could put a stiffleg up to bolster what sounds like your concern over thin section o/a...most horizontals had them, or at least provision for them.

Sliding a tube either into or over another won't do much in itself, the sliding contact will defeat the intent. Shrink fit, intermittent plug weld or mechanical fastening is required. It's possible that some sort of anaerobic fluid would work for a clearance fit but I speculate.

Filling the tube with concrete will add weight, but concrete shrinks as it cures...not sure where that leaves you. There are some non-shrink concoctions developed for machine tool bases, epoxy granite one I'm familiar with, but cost could be prohibitive.

I asked about balance not out of concern for tipping but ease of extension and some other concern that is in the back of my mind but can't articulate yet.

You could cut your existing o/a and machine spigot/socket to reassemble (sacrilege!)

You could make a plug(s) that fit the o/a holes that adapt round to rectangular section tube (available in lots of WT's), your o/a would be max. 3" deep.

If the knee isn't critical for Z you could put a stiffleg up to bolster what sounds like your concern over thin section o/a...most horizontals had them, or at least provision for them.

Sliding a tube either into or over another won't do much in itself, the sliding contact will defeat the intent. Shrink fit, intermittent plug weld or mechanical fastening is required. It's possible that some sort of anaerobic fluid would work for a clearance fit but I speculate.

Filling the tube with concrete will add weight, but concrete shrinks as it cures...not sure where that leaves you. There are some non-shrink concoctions developed for machine tool bases, epoxy granite one I'm familiar with, but cost could be prohibitive.

Re: tube / bar for Bridgeport M head mounting

Nod or not, the M should be presented towards the front. It will be more stable, controls accessible and the mill accessing the center of the table travel. Ideally it will be over the center of the knee.

-

Rich_Carlstedt

- Posts: 1755

- Joined: Sat Dec 21, 2002 12:16 am

- Location: Green Bay Wisconsin USA

- Contact:

Re: tube / bar for Bridgeport M head mounting

You can always add an adapter to the overarm.

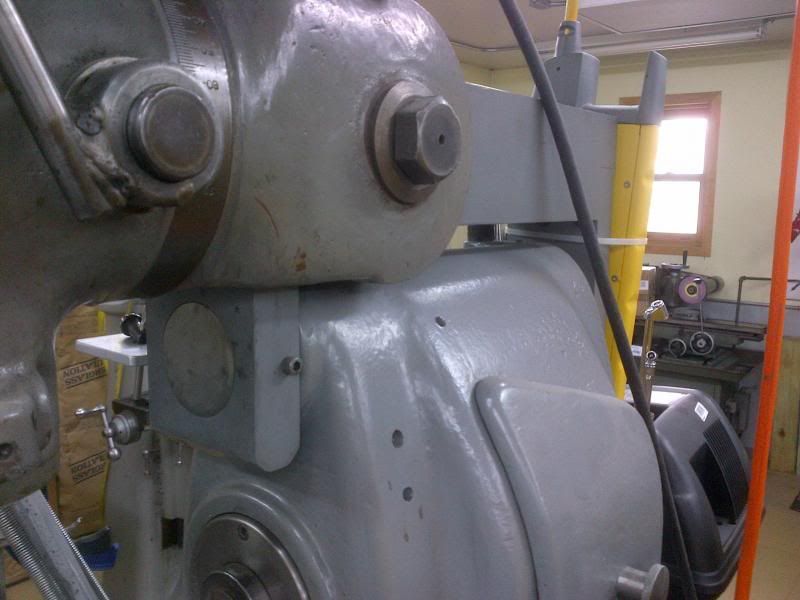

Here is a M Head I mounted to a Diamond mill.

I made brackets that fastened to the Overarm and attached a solid steel bar that allowed the Mhead adapter to nod if necessary and tilt was accomplished by loosening the Overarm clamps

Rich

Here is a M Head I mounted to a Diamond mill.

I made brackets that fastened to the Overarm and attached a solid steel bar that allowed the Mhead adapter to nod if necessary and tilt was accomplished by loosening the Overarm clamps

Rich

Last edited by Rich_Carlstedt on Sat Aug 20, 2016 6:29 pm, edited 1 time in total.

Re: tube / bar for Bridgeport M head mounting

Nicely done!Rich_Carlstedt wrote:You can always add an adapter to the overarm.

Steve

Re: tube / bar for Bridgeport M head mounting

Okay. Given that I said it "should be" mounted to the front, I didn't do it. Sorry, Steve, I keep forgetting your arbor support is built on the OA. Neither of us, for one reason or another, want to have to pull out the whole OA for transition. It goes back to that Duplex knuckle/ bracket/head mount. I know the sideways type were less expensive and should be more available. Perhaps you can trade your Duplex for one that works at the side. It will be around 5 1/2" off center of the knee but it will have degree nod and whatever tilt you lock it at. Then you can unlock it and slide it back for horizontal milling.

My "M" came with bracket ~5 1/2" diameter. Heck, that was some large milling machine.

My "M" came with bracket ~5 1/2" diameter. Heck, that was some large milling machine.

Re: tube / bar for Bridgeport M head mounting

That is, I believe, the standard ram for an M.spro wrote:My "M" came with bracket ~5 1/2" diameter. Heck, that was some large milling machine.

Not sure what this mount was for, but it definitely was NOT for a Bridgeport ram.

Steve

Re: tube / bar for Bridgeport M head mounting

Neither the 5 1/2" or 3 1/4" that we were discussing, were made for a Bridgeport milling machine. Both of these are the Duplex style. They allowed a Bridgeport M, H, R head to clamp either way to the OA of another mill. I was only noting that the 5 1/2" one went to a rather large horizontal Older milling machine. Many of these mills, B&S, K&T for example, went from a single 3 1/2" OA(B&S #2) to dual OAs. So this 5 1/2" adaptor/ bracket was made for machines built in the 1910's-1930's with a single large OA which had an arbor support which could be slid back to mount and use the front mount of the Duplex.