I did some checking and messing with it last night. I'm pretty sure the table isn't completely flat. With the table centered, I can level it in Y on the right, middle and be off a little on the left side - per the machinist level. I've tried various torque on the base to table bolts and that moves it a little, but not much. Have not done anything in X yet other than a rough set.

Knowing that a mill doesn't really have to be level to work, I'm thinking about these steps for doing the best with what it may be:

1) center table in X and Y, or Y center on spindle at least

2) torque base to table bolts to all the same torque reading - say 45 ft/lbs (don't think it matters)

3) use the "corner level" method - place level at 45 angle across table center, level using the feet pointed at by the level, switch to the other 45, level those feet, throw hands up, yell "TIME!"

4) tram head to table, shimming column as necessary to get Y as close as I can

5) deal with the other irregularities that are bound to be there, like variations as table travels.

It ain't no knee mill, but I'd like to get as good out of it as may be possible. Thanks for any suggestions.

Advice on leveling G0519

Advice on leveling G0519

Chris -

http://raceabilene.com/kelly/hotrod

"Check all parts for proper condition before operation; if normal safety precautions are noticed carefully, this machine can provide you withstanding of accurate service."

http://raceabilene.com/kelly/hotrod

"Check all parts for proper condition before operation; if normal safety precautions are noticed carefully, this machine can provide you withstanding of accurate service."

Re: Advice on leveling G0519

2) torque base to table bolts to all the same torque reading - say 45 ft/lbs (don't think it matters)Falcon67 wrote:I did some checking and messing with it last night. I'm pretty sure the table isn't completely flat. With the table centered, I can level it in Y on the right, middle and be off a little on the left side - per the machinist level. I've tried various torque on the base to table bolts and that moves it a little, but not much. Have not done anything in X yet other than a rough set.

Knowing that a mill doesn't really have to be level to work, I'm thinking about these steps for doing the best with what it may be:

1) center table in X and Y, or Y center on spindle at least

2) torque base to table bolts to all the same torque reading - say 45 ft/lbs (don't think it matters)

3) use the "corner level" method - place level at 45 angle across table center, level using the feet pointed at by the level, switch to the other 45, level those feet, throw hands up, yell "TIME!"

4) tram head to table, shimming column as necessary to get Y as close as I can

5) deal with the other irregularities that are bound to be there, like variations as table travels.

It ain't no knee mill, but I'd like to get as good out of it as may be possible. Thanks for any suggestions.

I'm assuming this is the x,y table your talking about. If your bolting htis together I would make the extra effort to debur, depaint, and check mating surfaces for flatness before mating the parts together, just as you would before mating the head to a block when engine building.

3) level

Yes do this if you have a bench that will not move and will maintain the level.

4) tram head to table, shimming column as necessary to get Z as close as I can

I would remove the column and do as in step 2, clean, debur, and flatten before checking tram. Before tramming check that the Z axis perpendicular to the table. Do this with a square from table to column or better with an indicator indicating a square on the table as you move the Z axis. You want to confirm that the spindle is parallel to the travel of the Z axis as well as being in tram with the table.

lg

no neat sig line

I am unique, just like everyone else.

Re: Advice on leveling G0519

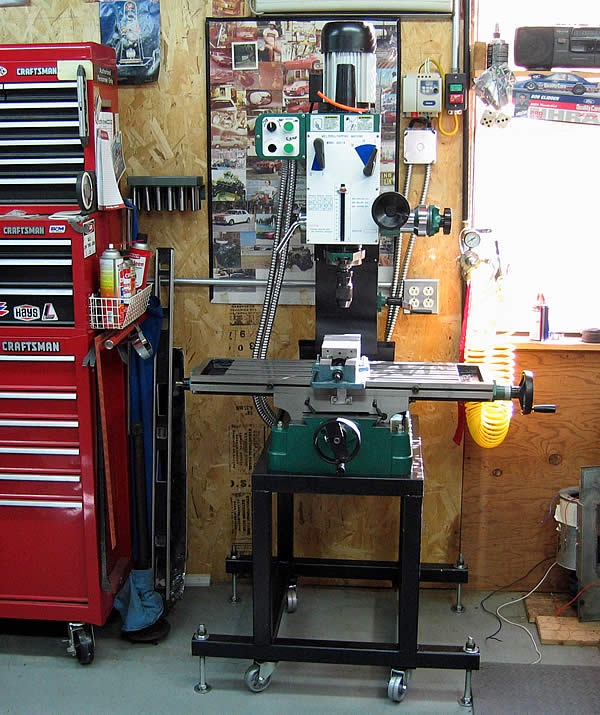

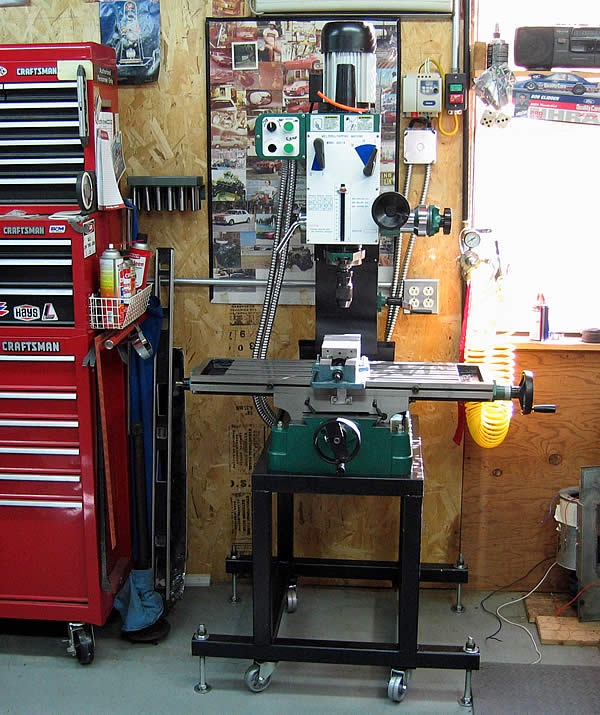

Thanks for the notes. #2 - means bolting the machine base to the stand. The stand is pretty stiff, made from 11 ga 2" steel tube.

Chris -

http://raceabilene.com/kelly/hotrod

"Check all parts for proper condition before operation; if normal safety precautions are noticed carefully, this machine can provide you withstanding of accurate service."

http://raceabilene.com/kelly/hotrod

"Check all parts for proper condition before operation; if normal safety precautions are noticed carefully, this machine can provide you withstanding of accurate service."

Re: Advice on leveling G0519

After I posted I found your other post on the stand and realized this is not a new machine to you. With that stand you have the opportunity to pull the base out of line IF the base or the stand is not flat. Does the machine sit flat on the stand before you bolt it down? If not then be careful that you don't tweek the base a bit pulling it down to the stand. Getting a setup like this flat, straight, perpendicular and level can be a mind bending ordeal.Falcon67 wrote:Thanks for the notes. #2 - means bolting the machine base to the stand. The stand is pretty stiff, made from 11 ga 2" steel tube.

lg

no neat sig line

I am unique, just like everyone else.