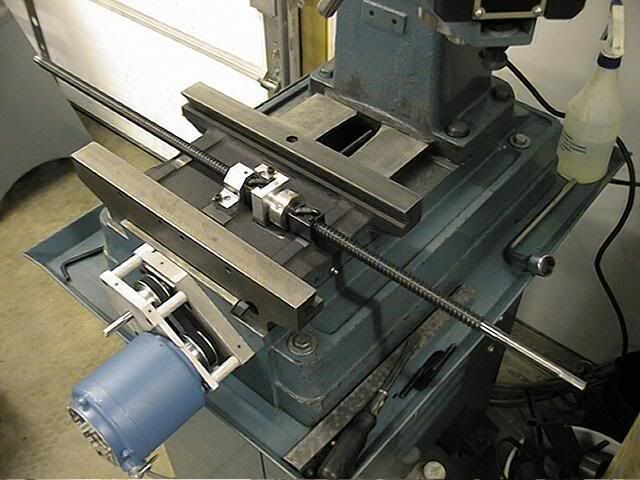

I spent a couple hundred hours (seems like) on the net researching the current methods and decided to design and fabricate my own conversion parts. I started by blueprinting the entire bottom end of the mill and shopping for motors and drive components. I got the belts and pulleys from econodrive and just about everything else from Ebay. (My starting goal was to complete the retrofit for <$800.)

I usually save the large projects for winter when I don't feel guilty for spending lots of time in my shop. Last winter the mechanicals were completed, this winter was the electronics and I'm just finishing up the 4th axis horizontal rotary table.

[/img]

[/img]

Anyone else using a 4th axis? If so, what for?

-Mike