Jose Rivera wrote:This was said to me working at a place where 98% of the work was forgings.

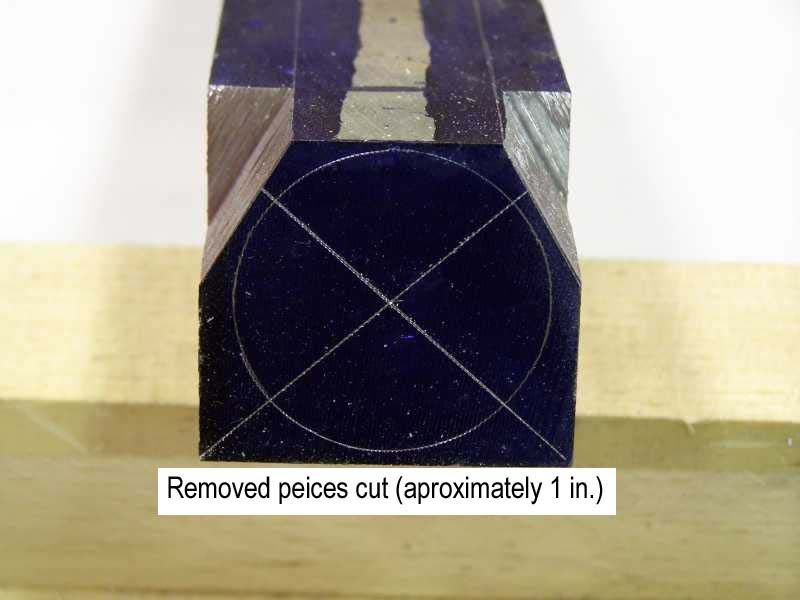

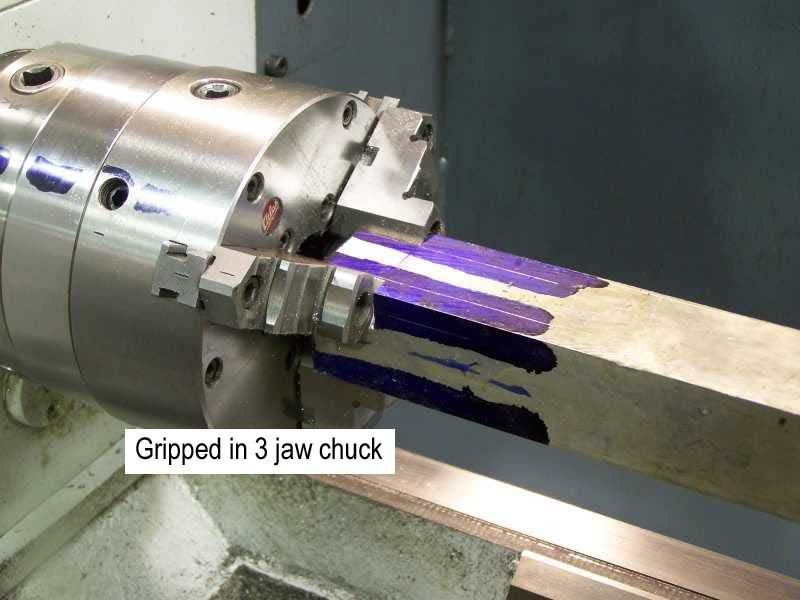

In this case one would be clamping with two jaws more likely. The stock is not round at all but with many flat marks where the press or hammer had beat on it.

Two jaws, unless they are gripping by the sides of the jaws, can't grip anything. There must be an opposing force in order for the chuck to grip, and that is created by the third jaw. Until all three make contact, the part continues to move towards average center of the chuck.

Even a forging, assuming a circle was intended, will have three points that are common to a circle. The reality is as long as the center of the jaw is in contact with the item being chucked, it should find average center of the part and load the jaws quite uniformly. Bill's comment of three points making a circle are on target in that regard. Were it not, three jaw chucks would be relatively useless. Even cold rolled material isn't perfectly round, to say nothing of hot rolled material.

A chuck with tight slides would likely not notice minor difference, nor would it be effected if they existed, assuming there's been no crash. Once a chuck has been through a crash, all bets are off, as they might be with the bearings in the headstock. All depends on the nature of the crash, and the damage done to the chuck jaw slides.

Damage to three jaw chucks, or even four jaw chucks, is more likely to occur by chucking items only by the tips of the jaws, where mechanical advantage tends to deform the slides. Rarely does one find an older chuck that has seen extended service that has not been so sprung.

still feel that the elders where right in this case.

Only in the case of a forging that was badly out of round, so much so that only two jaws could grip, because the sides of the jaws were making contact instead of the gripping surface. I wouldn't want to stand by the machine when it started in that scenario. Two jaws, unless diametrically opposed, will have no holding power-----and even then parts are subject to side movement. It takes support in no less than three places in more than 180° before a part is secure.

Harold