Kurt vise.

-

Black_Moons

- Posts: 545

- Joined: Wed Apr 15, 2009 6:57 pm

- Location: Canada, Bc

Kurt vise.

Hi, iv heard and read and looked at kurt vises.. wayy to expensive IMO, however the clones at $100~200 at busybee.. those look more like in my price range.. so im wondering, is there anything wrong with the kurt clones? I assume the jaws and ways and all will still be ground in a kurt vise clone.. maybe just not as pertty on the outside? any other faults I should look for?

[url]www.Cyberlazy.com[/url]

- GadgetBuilder

- Posts: 139

- Joined: Thu Apr 12, 2007 2:34 pm

- Location: Newtown, CT

I recently bought a 5" Kurt clone on Craigslist. It had been purchased 5 years ago but never used -- newer versions of these clones may differ (for better or worse). It is much easier to use than the grinding vise I had been using.

However, the moving jaw obviously rose as it tightened so I used a DTI on the mill table to measure the rise and found it moved 15 thou. I took it apart and saw the junction where the hemisphere is that provides down+forward force had some extra cast material that prevented proper contact with the hemisphere. A little Dremelizing fixed that but the moving jaw still rises about 3 thou as it is tightened.

Externally it is a nice looking vise. Internally the design looks as I'd expect a Kurt clone to look (not refined, just functional) but I assume the Kurt jaw doesn't rise at all. I'd be interested to hear how others have done with these vises and whether there is a simple fix for the rise issue.

John

However, the moving jaw obviously rose as it tightened so I used a DTI on the mill table to measure the rise and found it moved 15 thou. I took it apart and saw the junction where the hemisphere is that provides down+forward force had some extra cast material that prevented proper contact with the hemisphere. A little Dremelizing fixed that but the moving jaw still rises about 3 thou as it is tightened.

Externally it is a nice looking vise. Internally the design looks as I'd expect a Kurt clone to look (not refined, just functional) but I assume the Kurt jaw doesn't rise at all. I'd be interested to hear how others have done with these vises and whether there is a simple fix for the rise issue.

John

-

Jose Rivera

- Posts: 3803

- Joined: Wed Feb 21, 2007 9:21 pm

- Location: Vallejo California

I have a 4" clone that I bought from littlemachineshop.com three years ago.

I have no complaints, is precise enough and it has done a good job filling my needs.

One thing to remember as when measuring error with linear distances.

This applies either to adjusting the spindle zero to the table ("tramming") or the vise to the X or Y axis travel ... if one gets .0005 or error in ten inches of travel, this means that you have .00005 of error per inch.

I have no complaints, is precise enough and it has done a good job filling my needs.

One thing to remember as when measuring error with linear distances.

This applies either to adjusting the spindle zero to the table ("tramming") or the vise to the X or Y axis travel ... if one gets .0005 or error in ten inches of travel, this means that you have .00005 of error per inch.

There are no problems, only solutions.

--------------

Retired journeyman machinist and 3D CAD mechanical designer - hobbyist - grandpa

--------------

Retired journeyman machinist and 3D CAD mechanical designer - hobbyist - grandpa

-

Rich_Carlstedt

- Posts: 1760

- Joined: Sat Dec 21, 2002 12:16 am

- Location: Green Bay Wisconsin USA

- Contact:

As in all things, you get what you pay for.If you want a very accurate vise, with square parts and good clamping chacteristics, get a Kurt.

All others have various faults that prevent them from achieving this level of credibility.

That does not mean You should only buy a Kurt ($ concern) , but what level of manufacturing tolerence can you live with?

If you make parts where close is good enough, then any will work.

I noticed you mentioned one brand, thats good, because you want to know how close that brand is made.

Those here with that experiance may be able to help you

I would suggest you call the seller and ask ??

While at it, ask about return policey .

Start with a Kurt as far as tolerences and work from there.

If the supplier does not have "that data" that you want, consider it to be beyond acceptable levels. Proof is in the pudding as they say.

I have two Kurts, a 6 inch and a 5 inch. They are for all intents, dead nuts.

I like to work to .001 tolerances, so that is good for me, and easily done with them.

I was given a 4 inch clone, that I determined was made in India.

The jaw keys s were mounted with a hammer, they were .015 out of allignment, The moving jaw floated by .032" , the ball trust hold down (Kurt Patent) was crude and non functional, and the keyways were over .017 out of allignment.

It took me well over a day to accurize it ...close to my expectations, and i was lucky to access to a good surface grinder

That may not be true of all clones, but it was with the one given to me.

I understand the cost, I paid 485 dollars for the 5 inch vise in 1977.

A phenominal charge, but I have never regreted it .

To compare, I paid 600 for my Bridgeport the same year..

Rich

All others have various faults that prevent them from achieving this level of credibility.

That does not mean You should only buy a Kurt ($ concern) , but what level of manufacturing tolerence can you live with?

If you make parts where close is good enough, then any will work.

I noticed you mentioned one brand, thats good, because you want to know how close that brand is made.

Those here with that experiance may be able to help you

I would suggest you call the seller and ask ??

While at it, ask about return policey .

Start with a Kurt as far as tolerences and work from there.

If the supplier does not have "that data" that you want, consider it to be beyond acceptable levels. Proof is in the pudding as they say.

I have two Kurts, a 6 inch and a 5 inch. They are for all intents, dead nuts.

I like to work to .001 tolerances, so that is good for me, and easily done with them.

I was given a 4 inch clone, that I determined was made in India.

The jaw keys s were mounted with a hammer, they were .015 out of allignment, The moving jaw floated by .032" , the ball trust hold down (Kurt Patent) was crude and non functional, and the keyways were over .017 out of allignment.

It took me well over a day to accurize it ...close to my expectations, and i was lucky to access to a good surface grinder

That may not be true of all clones, but it was with the one given to me.

I understand the cost, I paid 485 dollars for the 5 inch vise in 1977.

A phenominal charge, but I have never regreted it .

To compare, I paid 600 for my Bridgeport the same year..

Rich

Hi all,

I am new to machining and so by no means an expert. However, after I got my mill/drill, I ordered a 4" machine vise (on a swivel base) from Enco. I paid about $100.00 for it. I noticed that when I set work on parallels I couldn't seem to keep the parallel tight under the work as I tightened the vise. I would tighten then tap the work and still the parallels were loose. To me this indicated that one side ( the moving jaw side) was lifting as I tightened the vise.

I recently bought a Kurt 675 from Enco (paid $368 on sale + 10% disc. + free shipping, got it in two days). It is like the difference between night & day in the way it operates. I am experiencing no noticeable lift on the movable jaw when I tighten the vise.

I am economically challenged, like many on this board I suspect, so I have purchased more than my share of cheap tools. In most cases they work out ok but occasionally I get burned (as in the case of the chinese vise). For me, certain fundamental pieces of equipment (such as a good vise) are worth spending the extra dollars on as they will have an effect on the quality of my work (and the time it takes to perform that work) over the long haul.

best wishes to all

Tim McMurray

I am new to machining and so by no means an expert. However, after I got my mill/drill, I ordered a 4" machine vise (on a swivel base) from Enco. I paid about $100.00 for it. I noticed that when I set work on parallels I couldn't seem to keep the parallel tight under the work as I tightened the vise. I would tighten then tap the work and still the parallels were loose. To me this indicated that one side ( the moving jaw side) was lifting as I tightened the vise.

I recently bought a Kurt 675 from Enco (paid $368 on sale + 10% disc. + free shipping, got it in two days). It is like the difference between night & day in the way it operates. I am experiencing no noticeable lift on the movable jaw when I tighten the vise.

I am economically challenged, like many on this board I suspect, so I have purchased more than my share of cheap tools. In most cases they work out ok but occasionally I get burned (as in the case of the chinese vise). For me, certain fundamental pieces of equipment (such as a good vise) are worth spending the extra dollars on as they will have an effect on the quality of my work (and the time it takes to perform that work) over the long haul.

best wishes to all

Tim McMurray

Jet GHB-1340 Lathe, Washington mill/drill (RF31)

-

Doug_Edwards

- Posts: 612

- Joined: Thu Apr 10, 2003 8:06 pm

- Location: No. Idaho

- Contact:

I have used both the Kurt vise and knock off imports. Some imports were down right pathic, but some were also usable. I have not found an import knock off that I liked as well as the Kurt, and vote with my wallet on this.

I agree with the previous posters that a good vise is very desireable.

Regards,

Doug

I agree with the previous posters that a good vise is very desireable.

Regards,

Doug

http://www.precisionlocomotivecastings.com/

Building a 70 ton Willamette in 1.6"

Building a 80 ton Climax in 1.6"

"Aim to improve!"

"Mine is not to question why, mine is just to tool and die"

Building a 70 ton Willamette in 1.6"

Building a 80 ton Climax in 1.6"

"Aim to improve!"

"Mine is not to question why, mine is just to tool and die"

- coal miner

- Posts: 479

- Joined: Tue Mar 18, 2008 6:19 pm

- Location: Southern Illinios

Black-Moons , the first vise I used was POS that came w/ my Grizzly 3616 that you couldn't set a parallel next to the fixed jaw . Soon ordered an Enco $ 180 Kurt - clone 6" , like a 4.6" jaw opening w/ swivel included . Took the swivel off , put it on the floor next to the Grizzly vise . Boat anchor # 2 . As stated by previous posters I got by OK w/ the clone , but still had lifting problems on the movable jaws . Made some Al soft jaws for it that had steps in them to hold small pieces . Got by OK till I had something to get dead-nuts on spec. and fought the lifting problem .

Got the same deal as tmc_31 from Enco $ 368.10 to the door , and have been very satisfied . The difference between night and day . Should have bought a Kurt the first time would have been $$$$ ahead ! My advice , save your money and Buy a Kurt .

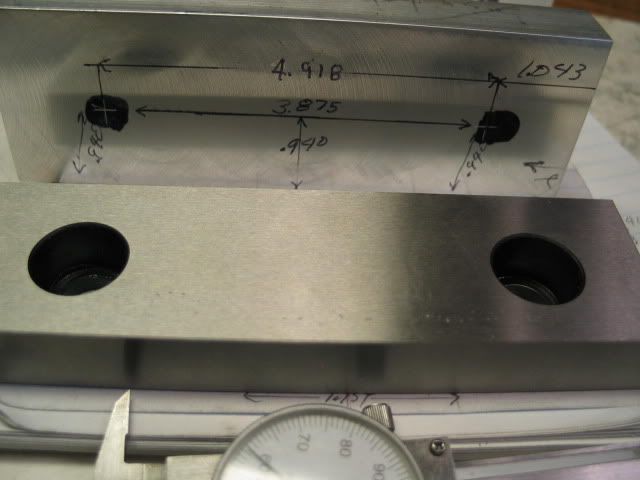

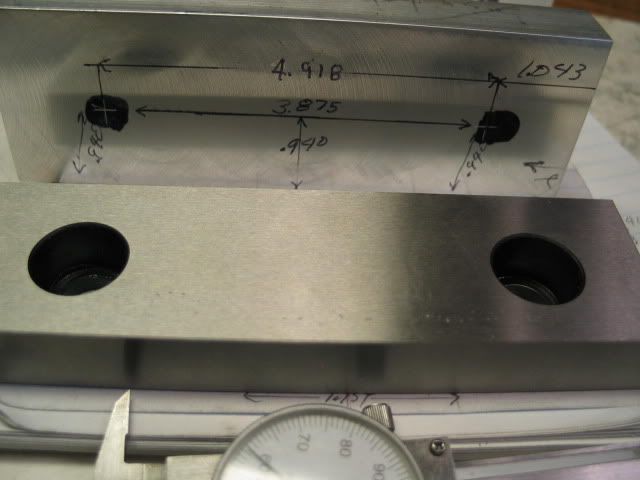

Some pics of the soft jaws . Note : these measurements worked for me , Do not take them for the gospel ! Started w/ a .750" x 2" x 4' piece of 6061 Al

Slot cut in the top w, a 60* bevel at the bottom so that a burr won't throw off the seating of the part .

Another pair of soft jaws and the supplied hard jaws from Kurt

Might use the old Enco for a press .

Got the same deal as tmc_31 from Enco $ 368.10 to the door , and have been very satisfied . The difference between night and day . Should have bought a Kurt the first time would have been $$$$ ahead ! My advice , save your money and Buy a Kurt .

Some pics of the soft jaws . Note : these measurements worked for me , Do not take them for the gospel ! Started w/ a .750" x 2" x 4' piece of 6061 Al

Slot cut in the top w, a 60* bevel at the bottom so that a burr won't throw off the seating of the part .

Another pair of soft jaws and the supplied hard jaws from Kurt

Might use the old Enco for a press .

The more I learn , The more I don't know !

- Mark Hockett

- Posts: 270

- Joined: Wed Feb 20, 2008 8:46 pm

- Location: Clinton WA.

Doug pretty well nailed it but I would like to add that I believe Kurt vises are one of the best values in the machine industry. You can't buy a US made 6" Wilton machinist bench vise as cheap as you can buy Kurt vise, and the level of precision in the Kurt is way higher. My friend bought a milling machine that came with a 4" Kurt clone. One of the jaws broke so he tried to order a new jaw, there were none available and the importer told him he needed to buy a complete new vise. He ended up buying a used Kurt 4" and loves it.

Mark Hockett

Kurt drawings are available for download in DXF as well as a few other formats if anyone needs to make soft jaws for other model vises.

http://kurtworkholding.com/downloads/cadfiles.php

http://kurtworkholding.com/downloads/cadfiles.php

Last edited by GlennW on Sun May 24, 2009 10:01 pm, edited 1 time in total.

Glenn

Operating machines is perfectly safe......until you forget how dangerous it really is!

Operating machines is perfectly safe......until you forget how dangerous it really is!

You can get used 6" Kurt vices for around $200-$250 if you look around and are patient. It will be good money spent.

If you want a 3" or 4" one, that's another story. They can get VERY expensive (more than a 6") because there are fewer of them around. I have seen a 3" for more than $300.

I gave up and got a South Bend vise for my Pratt & Whitney mill. There are problems with clearance on that mill, so I needed a small vise and the 4" SB fits nicely. The 3" Kurt would have been the right size, but too much money.

An 8" Kurt just went for $250 on ebay (and this would have been local for me):

http://cgi.ebay.com/ws/eBayISAPI.dll?Vi ... 0316894440

A 675 (6" jaw 7.5" opening) went for $250.

Keep an eye out for local auctions, as you will have an advantage over anyone that needs to have it shipped.

When I finally get the Brainard milling machine set up, I'll look for a Kurt, as I can use a 6" on that mill.

Steve

If you want a 3" or 4" one, that's another story. They can get VERY expensive (more than a 6") because there are fewer of them around. I have seen a 3" for more than $300.

I gave up and got a South Bend vise for my Pratt & Whitney mill. There are problems with clearance on that mill, so I needed a small vise and the 4" SB fits nicely. The 3" Kurt would have been the right size, but too much money.

An 8" Kurt just went for $250 on ebay (and this would have been local for me):

http://cgi.ebay.com/ws/eBayISAPI.dll?Vi ... 0316894440

A 675 (6" jaw 7.5" opening) went for $250.

Keep an eye out for local auctions, as you will have an advantage over anyone that needs to have it shipped.

When I finally get the Brainard milling machine set up, I'll look for a Kurt, as I can use a 6" on that mill.

Steve

-

Black_Moons

- Posts: 545

- Joined: Wed Apr 15, 2009 6:57 pm

- Location: Canada, Bc