BOB DEAN SIGHT GLASS UPDATE

- Trainman4602

- Posts: 3482

- Joined: Sat Oct 16, 2004 9:26 pm

- Location: New Jersey

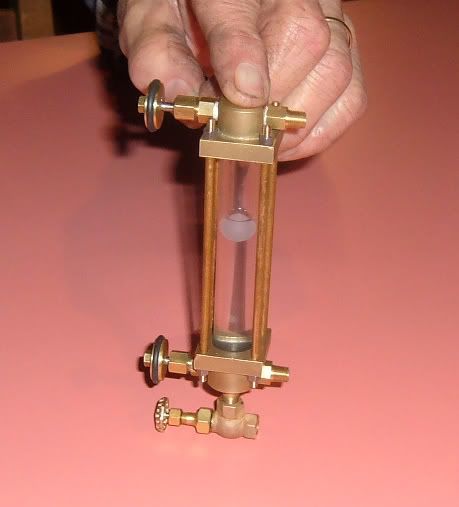

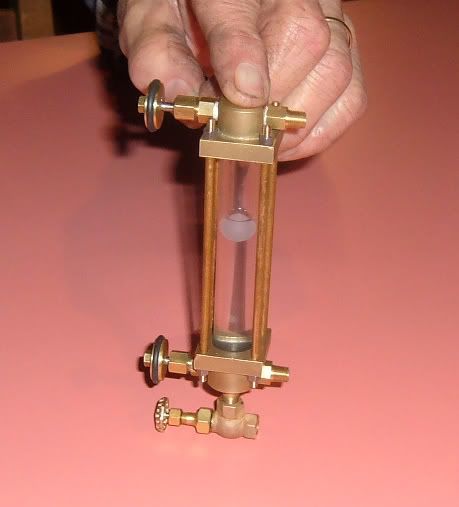

BOB DEAN SIGHT GLASS UPDATE

As mentioned in the latest video I had some trouble with the sight glass this weekend. It started to leak. Before we ran I cleaned the LSB from inside and I think I broke the silicone seal.

I have taken it apart and cleaned it.

I called Bob today and he suggested that I paint the inside red. He claims that the level will show red and above will be clear. We shall see.

I will use the red high temperature silicone to seal it. Bob suggested that when the silicone dries to scrape the access for the inside.

He also said that I could return it and he would send me another one at no charge. That’s more then I can say about some other supplier.

DON"T USE LSB 8000 It does protect the boiler but coats every thing else also. That's the trouble I'm having with the safety and other things sticking. Bob Dean agreed with me about the LSB It will coat the flutes on the reflex glass making it impossible to read.

The pictures are before and after

I have taken it apart and cleaned it.

I called Bob today and he suggested that I paint the inside red. He claims that the level will show red and above will be clear. We shall see.

I will use the red high temperature silicone to seal it. Bob suggested that when the silicone dries to scrape the access for the inside.

He also said that I could return it and he would send me another one at no charge. That’s more then I can say about some other supplier.

DON"T USE LSB 8000 It does protect the boiler but coats every thing else also. That's the trouble I'm having with the safety and other things sticking. Bob Dean agreed with me about the LSB It will coat the flutes on the reflex glass making it impossible to read.

The pictures are before and after

- tsph6500

- Posts: 1417

- Joined: Fri Dec 03, 2004 3:38 pm

- Location: West of Dunvegan, Ontario CANADA

- Contact:

Get Bent!

Following a tip from Curly, if you paint black & white or red & white stripes on a 45˚ angle the lines appear bent when under water and it is very easy to see.

Best regards,

Jim Leggett

Montreal Live Steamers

www.montreallivesteamers.org

A Founding Member of the Tinkerbell Scale Society - Northern Division

I'm an A.R.S.E. (Association of Railroad Steam Engineers)

Toad Swamp & Punk Hollow Railroad - Head Tycoon

The Juvenile Traction Company - CEO & Apprentice Machinist 3rd Class

White Mountain Central RR - Engineer & Fireman

Jim Leggett

Montreal Live Steamers

www.montreallivesteamers.org

A Founding Member of the Tinkerbell Scale Society - Northern Division

I'm an A.R.S.E. (Association of Railroad Steam Engineers)

Toad Swamp & Punk Hollow Railroad - Head Tycoon

The Juvenile Traction Company - CEO & Apprentice Machinist 3rd Class

White Mountain Central RR - Engineer & Fireman

-

Steve Bratina

- Posts: 1061

- Joined: Tue Jan 16, 2007 9:39 pm

- Location: Cambridge Ontario

Gauge Glass

I was shown a trick by the late Ed Tanski. If you cut out the bar code from a pop can. you can place it behind a tubular glass and read it much easier.

The tin allows you to form it to fit the glass.

The tin allows you to form it to fit the glass.

- Bill Shields

- Posts: 10524

- Joined: Fri Dec 21, 2007 4:57 am

- Location: 39.367, -75.765

- Contact:

Sight Glass Level

I guess I am just stone age about all this sight glass level stuff.

I find it easier to just do a Mitch Miller and 'follow the bouncing ball'

Granted, it isn't exactly something that you would find on the average locomotive, but my priorities are that I have to have something that even a blind man (Jim) can see this level in any light.

I also have been using the LSB products (4000 however) without problems related to coating things.

Maybe frequent blowdowns minimize the problem?

Protecting the boiler against corrosion / scaling is high on my list - much higher than maybe having to clean a glass occasionally.

I find it easier to just do a Mitch Miller and 'follow the bouncing ball'

Granted, it isn't exactly something that you would find on the average locomotive, but my priorities are that I have to have something that even a blind man (Jim) can see this level in any light.

I also have been using the LSB products (4000 however) without problems related to coating things.

Maybe frequent blowdowns minimize the problem?

Protecting the boiler against corrosion / scaling is high on my list - much higher than maybe having to clean a glass occasionally.

- Trainman4602

- Posts: 3482

- Joined: Sat Oct 16, 2004 9:26 pm

- Location: New Jersey

- Bill Shields

- Posts: 10524

- Joined: Fri Dec 21, 2007 4:57 am

- Location: 39.367, -75.765

- Contact:

8000

how much are you putting in a tender-full of water?

- Pennsy fan

- Posts: 727

- Joined: Thu Jun 17, 2004 1:50 am

- Location: Southern California.

Water treatment.

After a long chat with one of the chemist at LSB, he said a small amount is plenty for our scale. The Case 50 I run only needs an OZ to start and a shot after 1/2 way though the run day. And this is also comes from other steam tractor owners.

For the most part the LSB handles the suspended solids and leaves a film on the steel in the boiler. So unless you have a coating on the glass you won't have a problem.

If your having a buildup problem your water needs more than just the LSB.

In my job I have worked with water treatment plants and there tons to know on how to find out what is causing problems.

Things like chlorine, salt, oils, and plenty other things can make you go nuts.

In my case I have had some lime builtup on my glasses over time and a long q tip with lacquer thinner will get the glass clean.

BTW: Bob Dean did have a bad batch that did leak, I had two that had to be replaced after a few runs.

David.

For the most part the LSB handles the suspended solids and leaves a film on the steel in the boiler. So unless you have a coating on the glass you won't have a problem.

If your having a buildup problem your water needs more than just the LSB.

In my job I have worked with water treatment plants and there tons to know on how to find out what is causing problems.

Things like chlorine, salt, oils, and plenty other things can make you go nuts.

In my case I have had some lime builtup on my glasses over time and a long q tip with lacquer thinner will get the glass clean.

BTW: Bob Dean did have a bad batch that did leak, I had two that had to be replaced after a few runs.

David.

- Trainman4602

- Posts: 3482

- Joined: Sat Oct 16, 2004 9:26 pm

- Location: New Jersey

- Bill Shields

- Posts: 10524

- Joined: Fri Dec 21, 2007 4:57 am

- Location: 39.367, -75.765

- Contact:

Sight Glass

I made it from bar stock.

I don't think I have drawings - just came off the left side of my brain as I was spinning dials. Much of my loco is designed like that. Jim actually made some of the valve bits - he stems and packing glands. Again, straight from the left side of his brain also.

I can create some drawings if there is really a need.

The only critical dimension was that I needed a glass with a hole in the center large enough to allow the ball to float.

Other than that, it's just bits silver soldered together. The 'fittings' where the piping connects are the seats for the needle valves.

The valves are used to shut off the glass for blowing down / safety control.

Every time I steam up, I test the feed lines for free flow to be sure that the glass is giving an accurate level reading.

I don't think I have drawings - just came off the left side of my brain as I was spinning dials. Much of my loco is designed like that. Jim actually made some of the valve bits - he stems and packing glands. Again, straight from the left side of his brain also.

I can create some drawings if there is really a need.

The only critical dimension was that I needed a glass with a hole in the center large enough to allow the ball to float.

Other than that, it's just bits silver soldered together. The 'fittings' where the piping connects are the seats for the needle valves.

The valves are used to shut off the glass for blowing down / safety control.

Every time I steam up, I test the feed lines for free flow to be sure that the glass is giving an accurate level reading.