Seeing as I have been having my say I thought it would be appropriate to show my little box of sparks

This photo shows me doing what I like most, that is pulling a carriage load of happy passengers. The 3rd. Sunday of the month you will see me here.

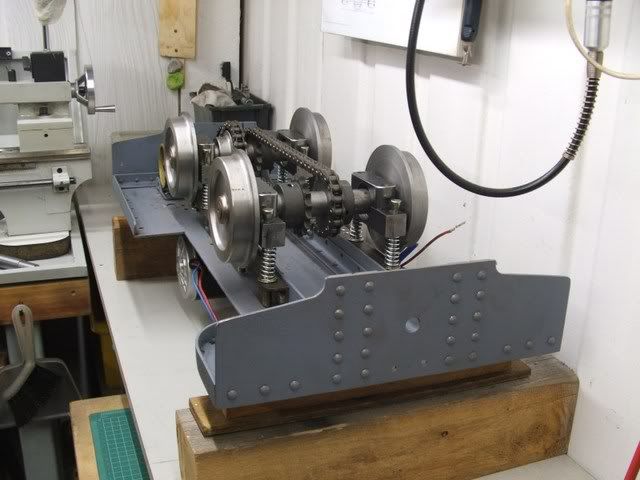

This loco was built to give me a project to do as I am learning to use my metalworking equipment consisting of a 9x20 lathe, pedestal drill stand and my mill which is a hacksaw and a handfull of files.

More intense projects are definitely on the drawing board ( what garbage, I have never used plans in my life. I design as I build ).