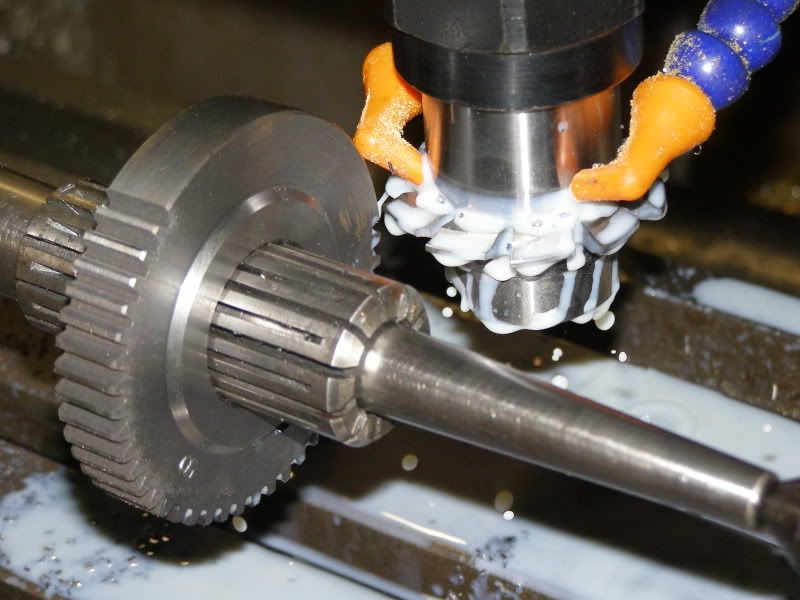

Set up and ready to start...

I set the cutter height with gage blocks. Measured the cutter thickness, divided by two, and subtracted that from the center height of the Dividing Head. Wrung up a stack of gage blocks, set them on the table just below the cutter, and brought the knee up to just touch the lower surface of the cutter with the gage blocks.

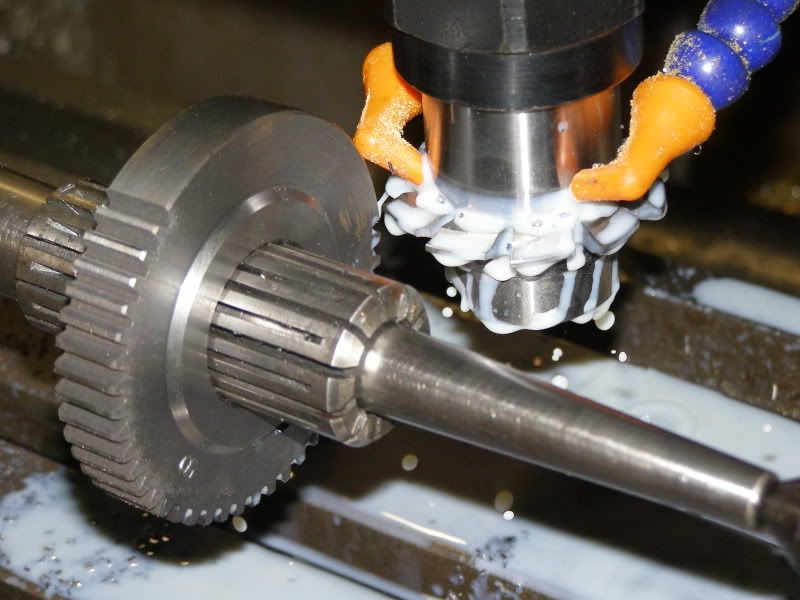

Half way around and working just fine.

Right after the half way point I decided to drizzle a little coolant on the cutter to see what happens. I believe Iron should be cut dry, but the cutter seemed to like it as it seemed quieter and the finish improved a little bit.

Made it back around and when I re-cut the "0" index tooth you could just hear the cutter touch it. I've got 50 full teeth and two blanks!

I checked the pitch diameter with my wires and got 3.0957" out of a perfect 3.0962". Looks like the "single cut" method works just fine, as did the new little dividing head!

I can see where a horizontal mill is the right tool for the job though.

It certainly was an interresting project as I learned a lot about spur gears and dividing heads.

Sorry this thing got drug out so long, just not enough "play time" lately, but it's great to be busy at my real job!