Home-made trepanning too/jig or...

- DICKEYBIRD

- Posts: 176

- Joined: Sat Feb 03, 2007 10:45 am

- Location: Collierville, TN

Home-made trepanning too/jig or...

...WWGWD. (What would Glenn (my hero) Wegman do?) I figure Glenn would do something kinda-sorta like this if he wanted to make a trepanning tool and was limited to the tools I have. Glenn's tool grinding adventures and pictures have always fascinated me and this is my attempt at grinding a complex tool.

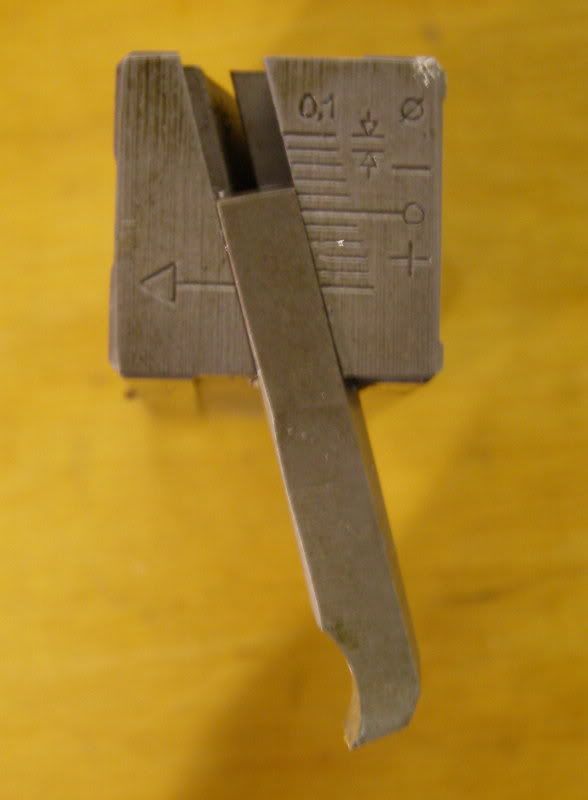

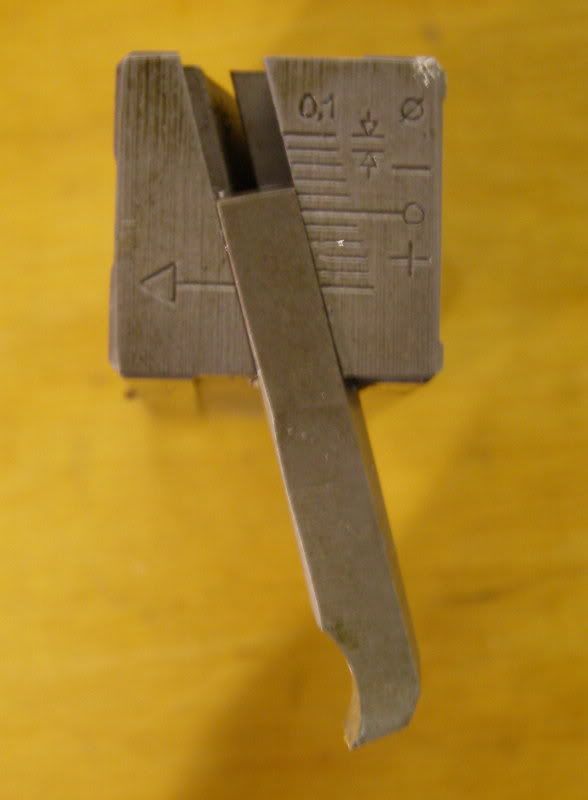

I sketched up the needed radii & angles in TurboCAD and spent quite a bit of time conjuring up a jig to grind a stick of 3/8” HSS to the proper shape. I cut up a old 3/8” drive extension to make a crude square collet and used a piece of 1” 4140 P.H. turned down to 1/2” on one end to fit my boring head. The boring head was chucked in the lathe, dialed in and the bit holder set over to the correct radii using the boring bar micrometer feed. The tool holder was adjusted carefully using the homemade jigs shown below to set the proper angles before tightening the clamp ring. The jigs have neodymium magnets imbedded in the ends to hold them in place. The angles are important to get the correct clearance ground in.

I don’t have a toolpost grinder so I made up a mount for a HF 4” angle grinder with an Enco 1.5” AO stone. Never knew they had stones with 5/8-11 threads but they do! Before starting the grind process, I printed up paper templates, glued them to the blank and sliced off as much as I could with a 4” abrasive cutoff disc mounted on an arbor in the mill.

The stone was way out of round so I had to make up a bar to hold my diamond dresser to true it up. I HATED that part. What a mess! I used a cut up Gatorade bottle as a shield to help contain the dust and coolant.

I made a spindle hand crank with a 15” long handle and used my biggest chuck for its extra mass to help control the grinding process as the tool was swung back & forth against the spinning stone. The little grinder turns pretty slow @ 11,000 rpm. It was a slow process but the tool came out very nice and exactly as drawn up.

Now I need to grind a chipbreaker; anybody know if they’re supposed to “lean” in towards the center of the circle to make the chips curl inwards?

edit: Sorry, screwed up my attachments and had to try again...I hope the show up this time.

I sketched up the needed radii & angles in TurboCAD and spent quite a bit of time conjuring up a jig to grind a stick of 3/8” HSS to the proper shape. I cut up a old 3/8” drive extension to make a crude square collet and used a piece of 1” 4140 P.H. turned down to 1/2” on one end to fit my boring head. The boring head was chucked in the lathe, dialed in and the bit holder set over to the correct radii using the boring bar micrometer feed. The tool holder was adjusted carefully using the homemade jigs shown below to set the proper angles before tightening the clamp ring. The jigs have neodymium magnets imbedded in the ends to hold them in place. The angles are important to get the correct clearance ground in.

I don’t have a toolpost grinder so I made up a mount for a HF 4” angle grinder with an Enco 1.5” AO stone. Never knew they had stones with 5/8-11 threads but they do! Before starting the grind process, I printed up paper templates, glued them to the blank and sliced off as much as I could with a 4” abrasive cutoff disc mounted on an arbor in the mill.

The stone was way out of round so I had to make up a bar to hold my diamond dresser to true it up. I HATED that part. What a mess! I used a cut up Gatorade bottle as a shield to help contain the dust and coolant.

I made a spindle hand crank with a 15” long handle and used my biggest chuck for its extra mass to help control the grinding process as the tool was swung back & forth against the spinning stone. The little grinder turns pretty slow @ 11,000 rpm. It was a slow process but the tool came out very nice and exactly as drawn up.

Now I need to grind a chipbreaker; anybody know if they’re supposed to “lean” in towards the center of the circle to make the chips curl inwards?

edit: Sorry, screwed up my attachments and had to try again...I hope the show up this time.

Milton in Tennessee

"Accuracy is the sum total of your compensating mistakes."

"Accuracy is the sum total of your compensating mistakes."

- DICKEYBIRD

- Posts: 176

- Joined: Sat Feb 03, 2007 10:45 am

- Location: Collierville, TN

Re: Home-made trepanning too/jig or...

...2 more pics that I couldn't get into the previous post.

Milton in Tennessee

"Accuracy is the sum total of your compensating mistakes."

"Accuracy is the sum total of your compensating mistakes."

Re: Home-made trepanning too/jig or...

Super nice job... I like your set-up for getting the side relief. I made a similar 3/8 square bit holder from a 3/8 drive socket, I use it with my 2C collets.

What project do you have in mind for this tool, face groove or trepan a disk from plate?

What project do you have in mind for this tool, face groove or trepan a disk from plate?

- DICKEYBIRD

- Posts: 176

- Joined: Sat Feb 03, 2007 10:45 am

- Location: Collierville, TN

Re: Home-made trepanning too/jig or...

Thanks!

I'm cutting discs from 5/8" steel plate in preparation for boring them (the plates) to final size to install bearings. The trepan blade is 3/8" long so I'll have to flip the plate to finish the cut.

I could have just drilled/bored a lot quicker but where's the fun in that? Besides, I'm frugal and the 1.75" discs left over will probably be a lot more useful down the road than a bucket of swarf!

Besides, I'm frugal and the 1.75" discs left over will probably be a lot more useful down the road than a bucket of swarf!

I'm making a standalone ER-32 lathe spindle powered by a treadmill motor/KBC speed control. I'll post some more pics when the project gets a bit further along.

I'm cutting discs from 5/8" steel plate in preparation for boring them (the plates) to final size to install bearings. The trepan blade is 3/8" long so I'll have to flip the plate to finish the cut.

I could have just drilled/bored a lot quicker but where's the fun in that?

I'm making a standalone ER-32 lathe spindle powered by a treadmill motor/KBC speed control. I'll post some more pics when the project gets a bit further along.

Milton in Tennessee

"Accuracy is the sum total of your compensating mistakes."

"Accuracy is the sum total of your compensating mistakes."

Re: Home-made trepanning too/jig or...

Wow!

That is some inventive fixturing, and it looks to have paid off as the tool looks excellent!

Very well thought out and executed!

Thanks!

That is some inventive fixturing, and it looks to have paid off as the tool looks excellent!

Very well thought out and executed!

Thanks!

Glenn

Operating machines is perfectly safe......until you forget how dangerous it really is!

Operating machines is perfectly safe......until you forget how dangerous it really is!

Re: Home-made trepanning too/jig or...

Sorry for the late response. It was a typical Monday and I had just a few too many things going on.

Here are a couple of views of trepanning tool bits for a Val Cut trepanning tool. They are a bit of a different setup than yours, but it shows the tip configuration.

They use left and right hand blades depending on wheather you need the bore or the slug.

This shows how they "drag" the cutter, which makes it cut smooth and chatter free. It also shows how the "chip breaker" is ground so that it gives it a bit of positive rake and some side rake as well for sort of a slicing action.

I realize that yours is more similar to a face grooving tool, but the tip configuration on these may be of some help for freeing up the cutting action.

The way these things cut is unbelievable!!!

I'd hate to try and grind one of these from a square tool bit as there are no two parallel sides.

Here are a couple of views of trepanning tool bits for a Val Cut trepanning tool. They are a bit of a different setup than yours, but it shows the tip configuration.

They use left and right hand blades depending on wheather you need the bore or the slug.

This shows how they "drag" the cutter, which makes it cut smooth and chatter free. It also shows how the "chip breaker" is ground so that it gives it a bit of positive rake and some side rake as well for sort of a slicing action.

I realize that yours is more similar to a face grooving tool, but the tip configuration on these may be of some help for freeing up the cutting action.

The way these things cut is unbelievable!!!

I'd hate to try and grind one of these from a square tool bit as there are no two parallel sides.

Glenn

Operating machines is perfectly safe......until you forget how dangerous it really is!

Operating machines is perfectly safe......until you forget how dangerous it really is!

- DICKEYBIRD

- Posts: 176

- Joined: Sat Feb 03, 2007 10:45 am

- Location: Collierville, TN

Re: Home-made trepanning too/jig or...

Thanks Glenn, them are some swoopy looking cutters! It's gonna take me a bit to visualize how those things are presented to the work. Are those tools you own? If so, when you get a spare moment could you post a couple pics showing their position relative to the work please?

Milton in Tennessee

"Accuracy is the sum total of your compensating mistakes."

"Accuracy is the sum total of your compensating mistakes."

Re: Home-made trepanning too/jig or...

Had to charge the batteries on the camera and didn't have the charger with me...

Glenn

Operating machines is perfectly safe......until you forget how dangerous it really is!

Operating machines is perfectly safe......until you forget how dangerous it really is!

Re: Home-made trepanning too/jig or...

You can see a short video of the tool working on this page... The site is french but the link is at the bottom right.

- DICKEYBIRD

- Posts: 176

- Joined: Sat Feb 03, 2007 10:45 am

- Location: Collierville, TN

Re: Home-made trepanning too/jig or...

Thanks Glenn, that clears it up for me. It *looks* like the side rake is ground to push the chips towards the outside but then again, they never go the way I think they'll go.

Obviously the designers of that tool know what they're doing so I'll do mine that way too. I hope to see some nice, shiny chips this weekend when I get back into the shop. Thank goodness, the weather is synching up with my days off for a change. It's supposed to be in the 50's instead of the low teens we're having now....brrrr! Even Tennessee gets cold in January.

ps: fourjc I don't see a linky...can you post it please. I'd love to see a commercial trepanning tool do its thing!

Obviously the designers of that tool know what they're doing so I'll do mine that way too. I hope to see some nice, shiny chips this weekend when I get back into the shop. Thank goodness, the weather is synching up with my days off for a change. It's supposed to be in the 50's instead of the low teens we're having now....brrrr! Even Tennessee gets cold in January.

ps: fourjc I don't see a linky...can you post it please. I'd love to see a commercial trepanning tool do its thing!

Milton in Tennessee

"Accuracy is the sum total of your compensating mistakes."

"Accuracy is the sum total of your compensating mistakes."

Re: Home-made trepanning too/jig or...

The cutting edge is below the centerline so they call it a drag tool..

cut and past this in your browser. I will check it out after the I post it.

http://www.vaco-france.com/vaco-pages/vaco-video-01.htm

cut and past this in your browser. I will check it out after the I post it.

http://www.vaco-france.com/vaco-pages/vaco-video-01.htm

- DICKEYBIRD

- Posts: 176

- Joined: Sat Feb 03, 2007 10:45 am

- Location: Collierville, TN

Re: Home-made trepanning too/jig or...

Wow, cool video! Methinks they were showing off a bit. Big hole, interrupted cut on the edge of a steel beam. Probably a bit beefier mill than my X-3 too.

Milton in Tennessee

"Accuracy is the sum total of your compensating mistakes."

"Accuracy is the sum total of your compensating mistakes."