Kozo A3 in 1.5" scale - new project

Moderator: Harold_V

Re: Kozo A3 in 1.5" scale - new project

Aw... I new boucing baby machinist

Re: Kozo A3 in 1.5" scale - new project

Having taken 2 weeks off for NAMES and then some minor surgery, I was eager to get back to work on the A3.

The first thing was tapping the 24 8-32 mounting holes for the cylinder heads. This went quicker than I expected as CI taps very nicely. I used the mill/DRO to position the tap vertically and start the first couple of threads, then finished with a tap wrench as usual.

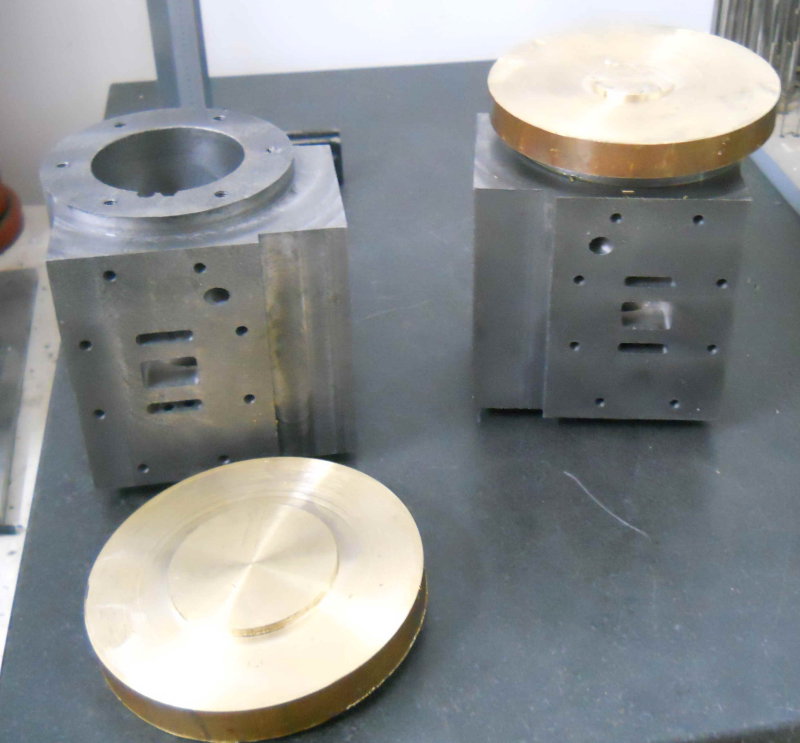

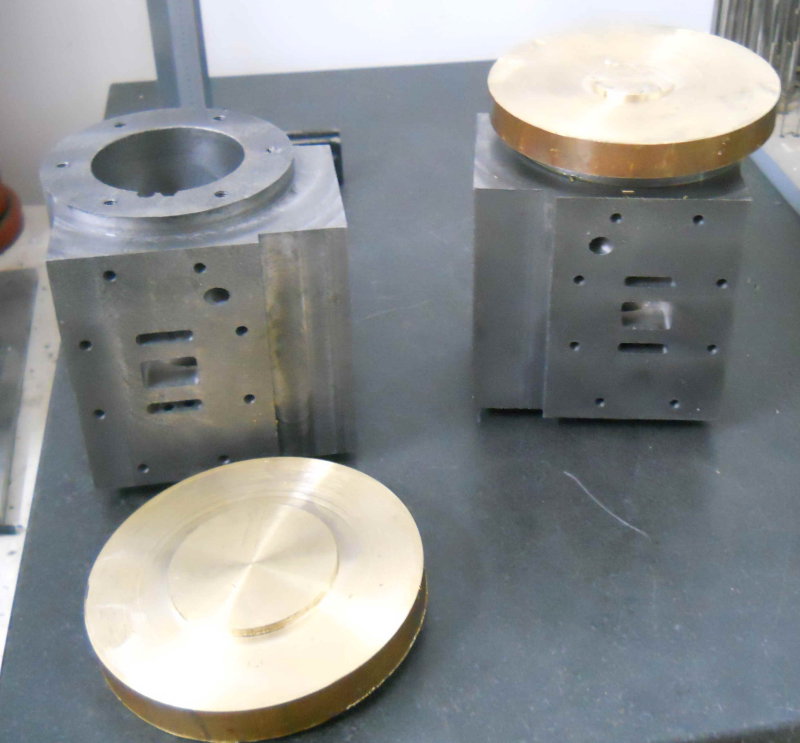

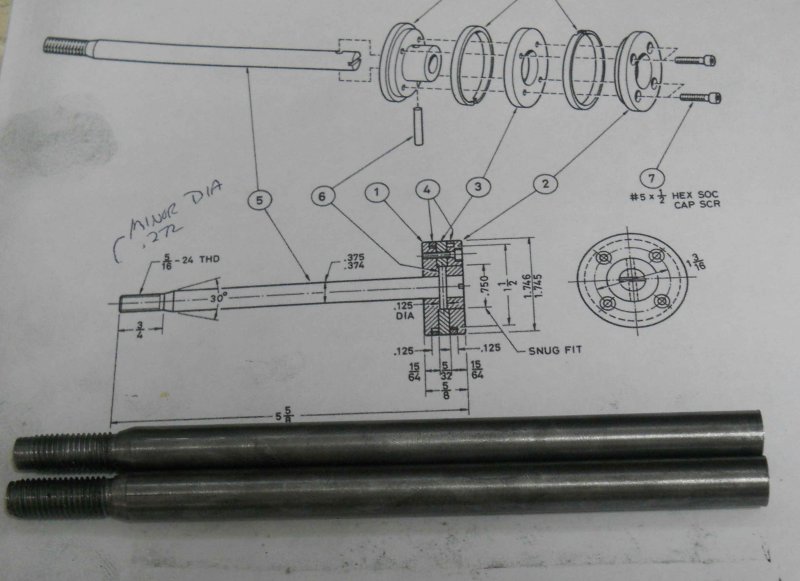

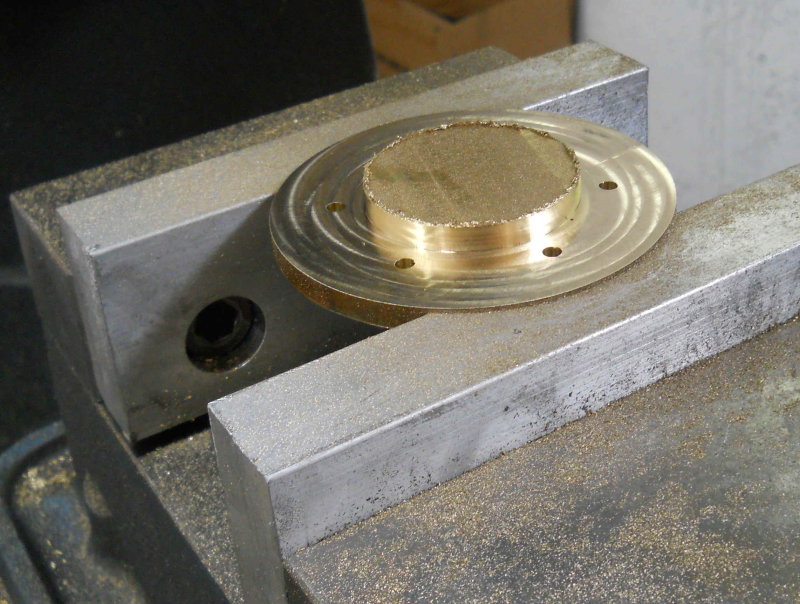

I bought a piece of 3.5" brass rod at NAMES that I thought would make up the front cylinder heads. It was about 1.5" long but the ends weren't square. I mounted in the lathe, squared the faces, and then faced the spigots that fit into the cylinder bore on both ends. The resulting piece was now 1.32" long. Now I needed to split this into 2 thin discs. Starting with a 1/16" parting tool, it became obvious that this wasn't going to work, as the tool was flexing. I switched to a 1/8" blade and slowly cut using back gear and ~150rpm. When the diameter was down to 1", I cut the rest with a hacksaw.

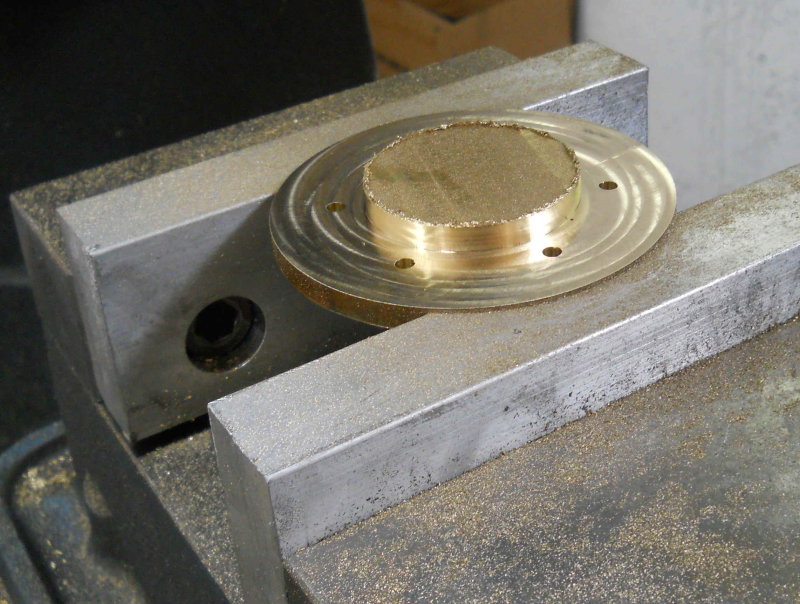

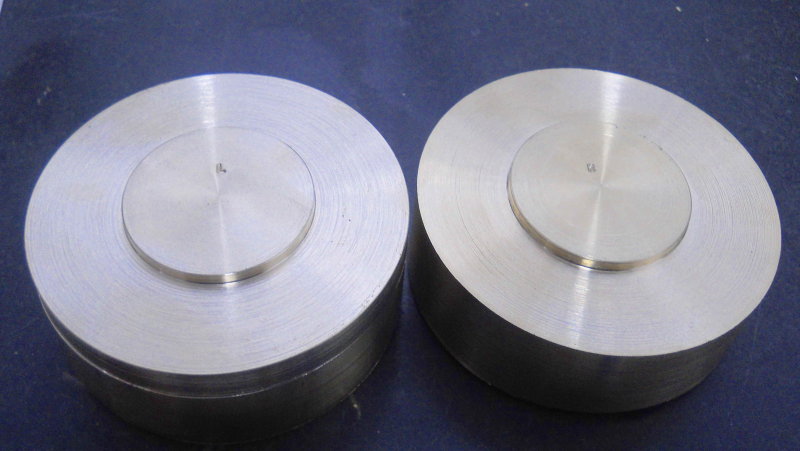

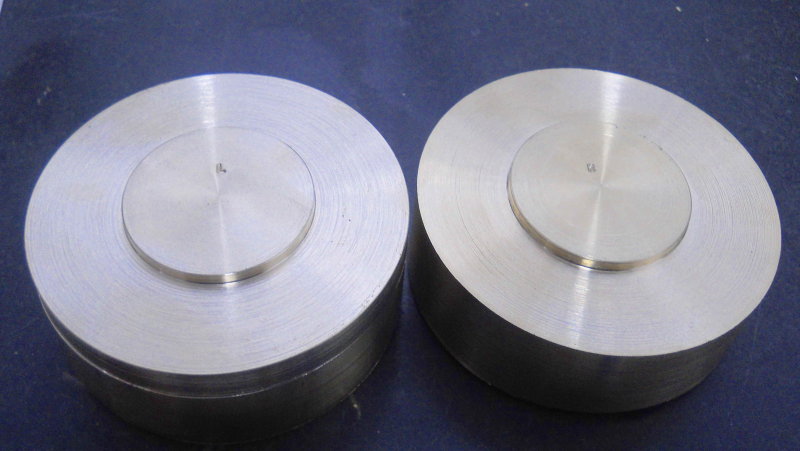

Here's the result. The rest of the machining will be done on the CNC mill.

I also bought a piece of 4" diameter brass rod for the rear cylinder covers. I'm hoping it's long enough to part on the bandsaw.

I also

The first thing was tapping the 24 8-32 mounting holes for the cylinder heads. This went quicker than I expected as CI taps very nicely. I used the mill/DRO to position the tap vertically and start the first couple of threads, then finished with a tap wrench as usual.

I bought a piece of 3.5" brass rod at NAMES that I thought would make up the front cylinder heads. It was about 1.5" long but the ends weren't square. I mounted in the lathe, squared the faces, and then faced the spigots that fit into the cylinder bore on both ends. The resulting piece was now 1.32" long. Now I needed to split this into 2 thin discs. Starting with a 1/16" parting tool, it became obvious that this wasn't going to work, as the tool was flexing. I switched to a 1/8" blade and slowly cut using back gear and ~150rpm. When the diameter was down to 1", I cut the rest with a hacksaw.

Here's the result. The rest of the machining will be done on the CNC mill.

I also bought a piece of 4" diameter brass rod for the rear cylinder covers. I'm hoping it's long enough to part on the bandsaw.

I also

-

pkastagehand

- Posts: 156

- Joined: Thu Nov 03, 2005 9:12 am

- Location: Holland MI

Re: Kozo A3 in 1.5" scale - new project but OT a bit

I recently read Shop Class as Soulcraft by Matthew Crawford which discusses among other things the separation of thinking from doing and how thinking has been "glamorized" and doing (blue collar) has gotten a bad wrap. But the most satisfied of workers tend to be the ones that get to do both. Maybe that is why we all like to "work" in our shops. Lots of thinking and problem solving going on but also the satisfaction of doing and having something we've created to show others when we're done.Rwilliams wrote:Snipped for brevity. ... I find at this age level they enjoy the hands on experience more than all of the math and thinking that has to be done. ....

Robert

One of my sons has taken an interest in metals after not showing any interest for the first 24 or 25 years. Blacksmithing but maybe machining will come later...

Keep encouraging your daughter.

Paul

Re: Kozo A3 in 1.5" scale - new project

Where were girls like that when I was in high school?

Nobody is going to be able to tell that girl what she can't do!

Just let her know that all the setup time is what makes the machining time productive and enjoyable.

Steve

Nobody is going to be able to tell that girl what she can't do!

Just let her know that all the setup time is what makes the machining time productive and enjoyable.

Steve

Re: Kozo A3 in 1.5" scale - new project

I'm not sure the shop session "took", but maybe in the future she'll come up with something she wants to make. I'm going to makes some engraved nametags for their instrument cases for band camp this summer.

Recovering from surgery, I'm limited in what I can do in the shop (no lifting). So I have a backlog of stuff waiting until I can go full speed. Today I finished tapping all the holes on the cylinders: 8-32 for the steam chest and 10-32 for the tee/frame.

I also got my shipment in from Speedy Metals. A length of CI bar for making the steam chests, and two lengths of SS416 rod for the piston and valve rods, so those are now on the todo list.

I also tried out the 6-7 micrometer I picked up at NAMES for measuring the outer frame width vs. the length of the tee. I have about 3/8 to take off the tee so that it matches the frame. That way the cylinders, frame, and tee all fit together flush on both sides.

Recovering from surgery, I'm limited in what I can do in the shop (no lifting). So I have a backlog of stuff waiting until I can go full speed. Today I finished tapping all the holes on the cylinders: 8-32 for the steam chest and 10-32 for the tee/frame.

I also got my shipment in from Speedy Metals. A length of CI bar for making the steam chests, and two lengths of SS416 rod for the piston and valve rods, so those are now on the todo list.

I also tried out the 6-7 micrometer I picked up at NAMES for measuring the outer frame width vs. the length of the tee. I have about 3/8 to take off the tee so that it matches the frame. That way the cylinders, frame, and tee all fit together flush on both sides.

Re: Kozo A3 in 1.5" scale - new project

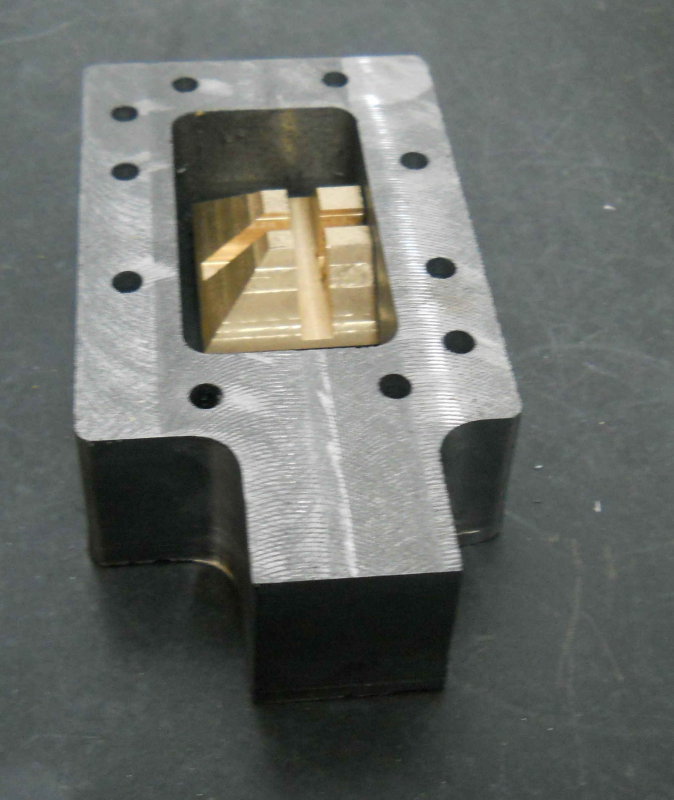

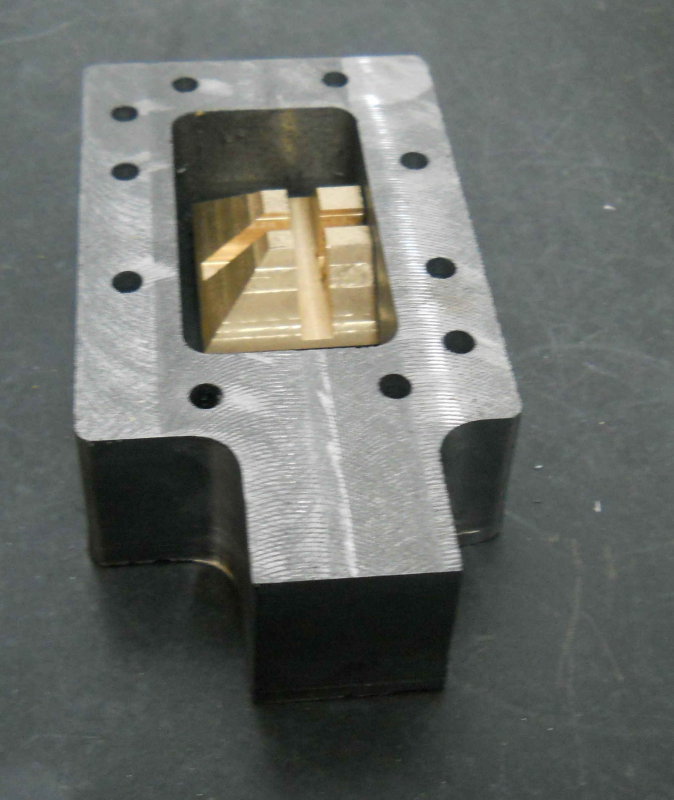

I was able to trim the tee so that it and the cylinders will fit flush to the outside of the frames. Then it was on to work on the steam chests. While these are relatively simple. I still put in a lot of hours over the past three days.

I had a 13" bar of 3.25x1.5 CI, enough for the two steam chests and a third if I screw up. After sawing into thirds and squaring each piece, I had a couple of these.

The bars are advertised to finish 1/4" less than the size. Since the chests are 2-3/16" wide, I would not have had much allowance with a 2-1/4 width. However, that meant a lot of CI turned into swarf.

Next, used the CNC mill to drill the mounting holes and machine the outer profile. I added two additional holes which will attach to the cylinders but be countersunk and not go through the cover. These will allow the cover to be removed without the steam chest moving. The larger hole in the center is just to allow milling the center pocket with a non-center-cutting endmill.

Next the bottom 1/4" is milled off using the bridgeport, leaving the steam chest 1" thick. The slide valve does appear to fit.

Rather than turn the spigot on the lathe, I used the CNC mill to do it faster.

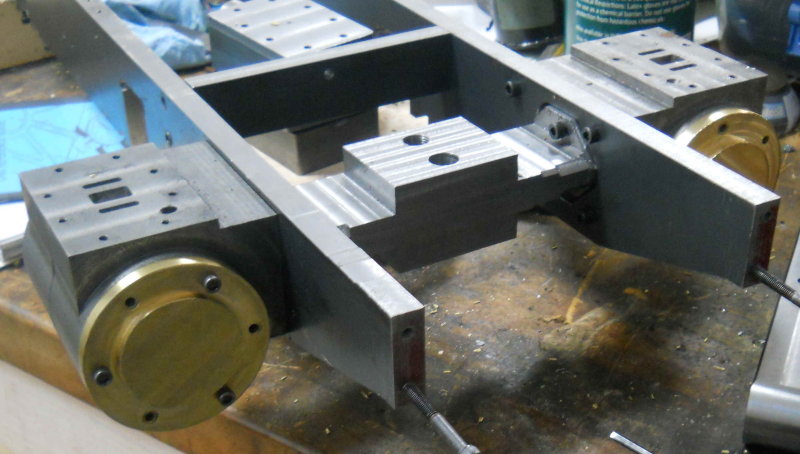

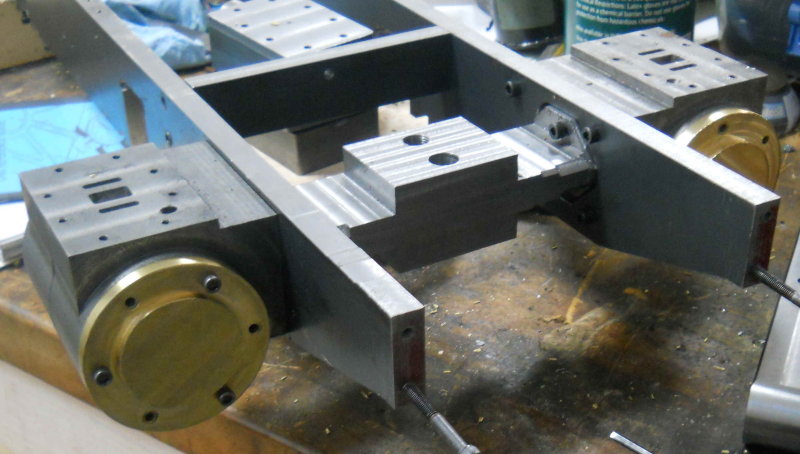

Finally today, put the tee and cylinders together on the frame. I had to trim the ends of the tee a bit as it's a close fit in the frame pocket.

Still to do on the steam chests:

1) Bore a pocket in the spigot for the bushing (yet to be made) and o-ring, then the threaded hole for the bushing retaining screw.

2) Drill the hole for the valve spindle; I will do this with the bushing in place so that all is concentric.

3) Bore the passage in the inner wall to expose the steam admission port in the cylinder.

4) Countersink the two extra mounting holes

I had a 13" bar of 3.25x1.5 CI, enough for the two steam chests and a third if I screw up. After sawing into thirds and squaring each piece, I had a couple of these.

The bars are advertised to finish 1/4" less than the size. Since the chests are 2-3/16" wide, I would not have had much allowance with a 2-1/4 width. However, that meant a lot of CI turned into swarf.

Next, used the CNC mill to drill the mounting holes and machine the outer profile. I added two additional holes which will attach to the cylinders but be countersunk and not go through the cover. These will allow the cover to be removed without the steam chest moving. The larger hole in the center is just to allow milling the center pocket with a non-center-cutting endmill.

Next the bottom 1/4" is milled off using the bridgeport, leaving the steam chest 1" thick. The slide valve does appear to fit.

Rather than turn the spigot on the lathe, I used the CNC mill to do it faster.

Finally today, put the tee and cylinders together on the frame. I had to trim the ends of the tee a bit as it's a close fit in the frame pocket.

Still to do on the steam chests:

1) Bore a pocket in the spigot for the bushing (yet to be made) and o-ring, then the threaded hole for the bushing retaining screw.

2) Drill the hole for the valve spindle; I will do this with the bushing in place so that all is concentric.

3) Bore the passage in the inner wall to expose the steam admission port in the cylinder.

4) Countersink the two extra mounting holes

Re: Kozo A3 in 1.5" scale - new project

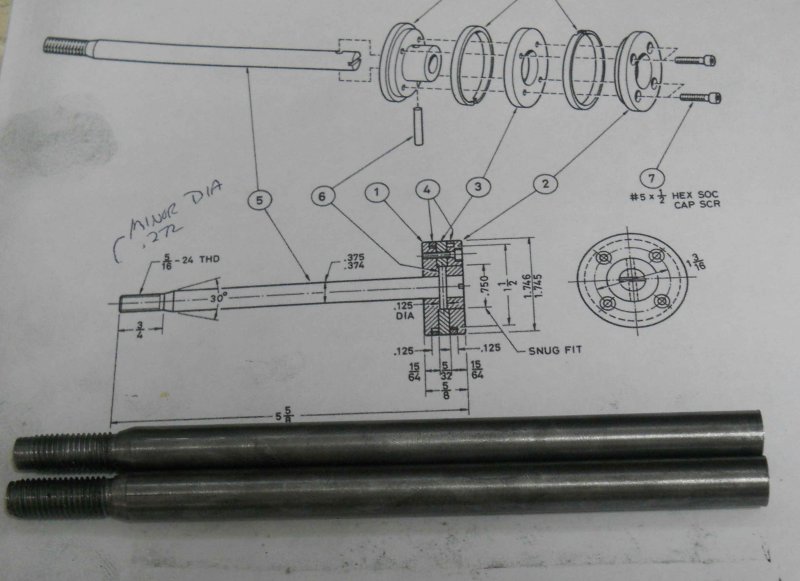

I spent the morning turning the valve spindles (fig 17-6, p. 103). Material is .25" 416 stainless rod. One end is threaded 1/4-20 to match the yokes my daughter helped make, and the other 10-32 matching the width of the slots in the valve.

Then it was fairly quick to countersink the two extra holes in the steam chest for 8-32 SHCS, using a 5/16 endmill.

Then I started work on the steam chest bore. The design here, as with the piston rod and axle pump plunger, is to seal the spindle with a Viton O-ring and guide the rod with a bronze bushing, which also acts to retain the o-ring within the steam chest spigot. For the valve, the o-ring is a size 2-010. Using Kozo's allowances on the 3/4 scale plan, I computed that the bore for the bushing needs to be .382 in diameter. I happened to have a .380 reamer acquired in an auction lot at a closed shop, so hopefully that will be close enough.

So the machine ops for the spigot, after centering on the Bridgeport, were:

1) Through drill a clearance hole. The closest drill I had is an F (.257)

2) Machine a flat hole .432" deep using a .375 endmill

3) Ream with the .380 reamer

Here's where I ended the day on the first chest. Once the bushing are made, I will drill/ream the .250" through hole with the bushing in place in the chest. It's not as critical to be concentric since the valve has "wiggle room", but for the piston rod I will need the bushing's hole to be dead nuts with the cylinder bore. I plan to use a similar technique there,

Then it was fairly quick to countersink the two extra holes in the steam chest for 8-32 SHCS, using a 5/16 endmill.

Then I started work on the steam chest bore. The design here, as with the piston rod and axle pump plunger, is to seal the spindle with a Viton O-ring and guide the rod with a bronze bushing, which also acts to retain the o-ring within the steam chest spigot. For the valve, the o-ring is a size 2-010. Using Kozo's allowances on the 3/4 scale plan, I computed that the bore for the bushing needs to be .382 in diameter. I happened to have a .380 reamer acquired in an auction lot at a closed shop, so hopefully that will be close enough.

So the machine ops for the spigot, after centering on the Bridgeport, were:

1) Through drill a clearance hole. The closest drill I had is an F (.257)

2) Machine a flat hole .432" deep using a .375 endmill

3) Ream with the .380 reamer

Here's where I ended the day on the first chest. Once the bushing are made, I will drill/ream the .250" through hole with the bushing in place in the chest. It's not as critical to be concentric since the valve has "wiggle room", but for the piston rod I will need the bushing's hole to be dead nuts with the cylinder bore. I plan to use a similar technique there,

Re: Kozo A3 in 1.5" scale - new project

Today I just had a few hours after lunch to work, so I finished all the machining remaining on the steam chests, and decided to start on the piston rods. Material is .375" 416 SS, which machines quite nicely. I single pointed the 5/16-24 threads to about 80%, then finished with a die. I still need to drill and ream the cross pin hole and cut the slots on the ends, used for adjusting the piston travel during tuning.

Re: Kozo A3 in 1.5" scale - new project

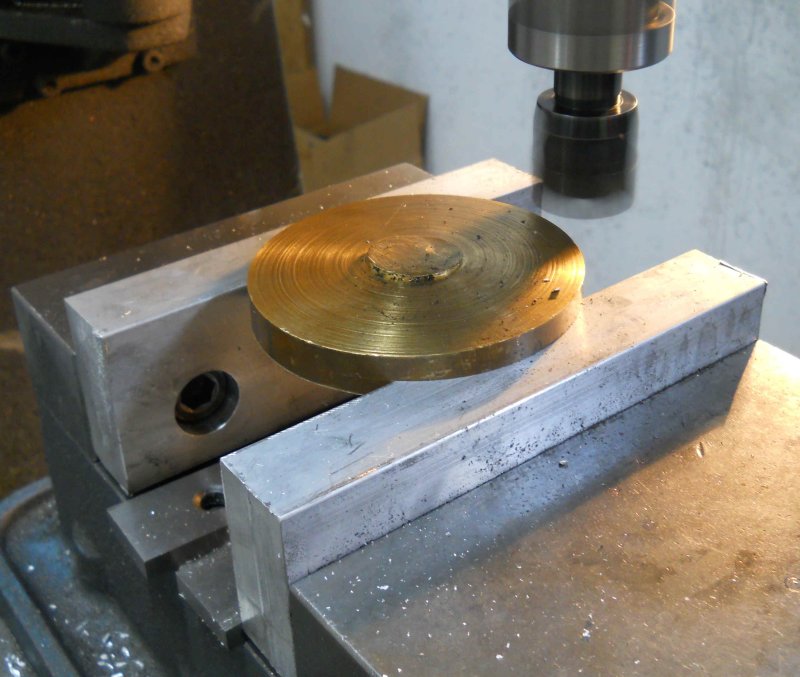

The past couple of shop sessions were dedicated to finishing the front cylinder heads. Previously I had turned the mating surfaces and bore spigot from a piece of 3" brass round. To hold these discs, I now needed to make a new set of vise soft jaws.

I made two sets from a 6' bar of 1"x2" aluminum ordered from Enco. This bar costs about $11/foot shipped, so for 6" jaws that's $11/pair/ I could have ordered 10 pairs already made from "monsterjaws" on eBay for $113 shipped. The reason I decided to go this route was that I can also make jaws for my 4" vises from the same bar. In any case, it took about 90 minutes to cut, mill, drill, and countersink 4 jaws. These are a bit larger than the standard hard jaws as can be seen here:

Next I milled a circular pocket in the jaws to hold a piece of round aluminum, then drilled and tapped 8-32 holes to match the pattern for the heads.

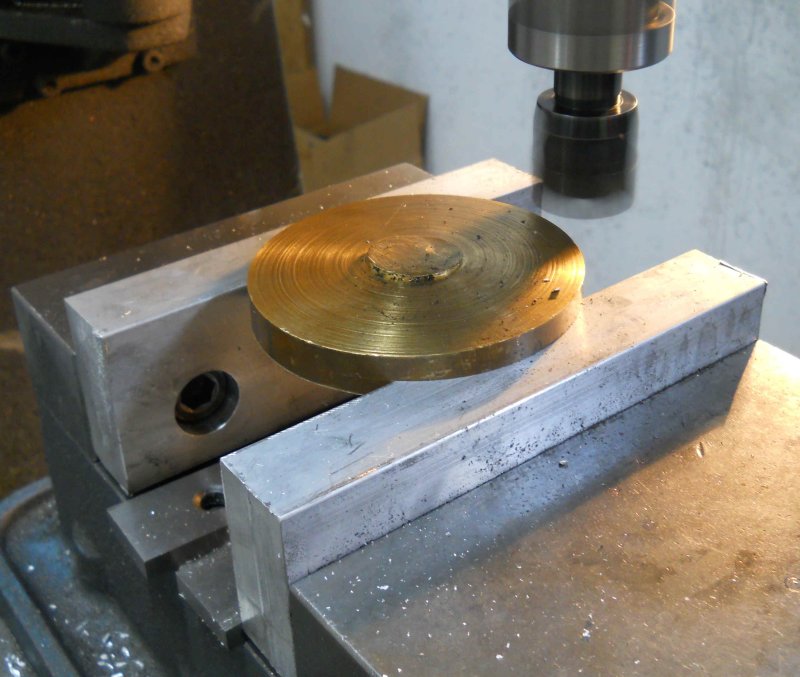

Next I milled a 3" pocket in the jaws to hold the heads so that I could face the outer side.

Next, reverse the head in the pocket and use the coax indicator to center on the bore spigot.

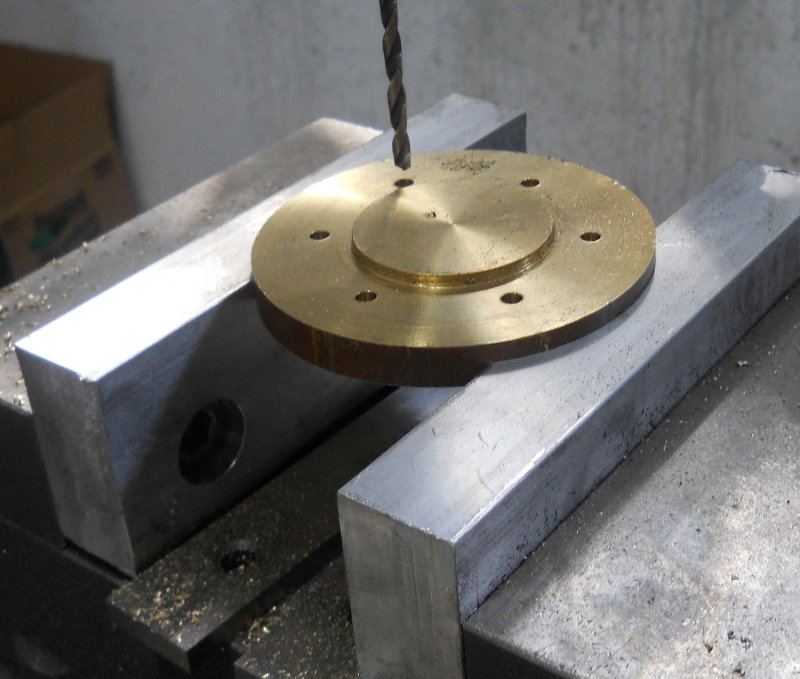

Now I can accurately drill the 8-32 clearance holes centered on the spigot.

Now the head can be reversed and the outer spigot milled.

Finally, screw the head to the fixture and mill the outer edge to finish diameter.

Mounted on the cylinders; like Jesse Banning's versions, I plan to leave the heads exposed and not machine the covers. I have ordered some model-scale hex cap screws to attach the heads, as well as the steam chests.

I made two sets from a 6' bar of 1"x2" aluminum ordered from Enco. This bar costs about $11/foot shipped, so for 6" jaws that's $11/pair/ I could have ordered 10 pairs already made from "monsterjaws" on eBay for $113 shipped. The reason I decided to go this route was that I can also make jaws for my 4" vises from the same bar. In any case, it took about 90 minutes to cut, mill, drill, and countersink 4 jaws. These are a bit larger than the standard hard jaws as can be seen here:

Next I milled a circular pocket in the jaws to hold a piece of round aluminum, then drilled and tapped 8-32 holes to match the pattern for the heads.

Next I milled a 3" pocket in the jaws to hold the heads so that I could face the outer side.

Next, reverse the head in the pocket and use the coax indicator to center on the bore spigot.

Now I can accurately drill the 8-32 clearance holes centered on the spigot.

Now the head can be reversed and the outer spigot milled.

Finally, screw the head to the fixture and mill the outer edge to finish diameter.

Mounted on the cylinders; like Jesse Banning's versions, I plan to leave the heads exposed and not machine the covers. I have ordered some model-scale hex cap screws to attach the heads, as well as the steam chests.

Re: Kozo A3 in 1.5" scale - new project

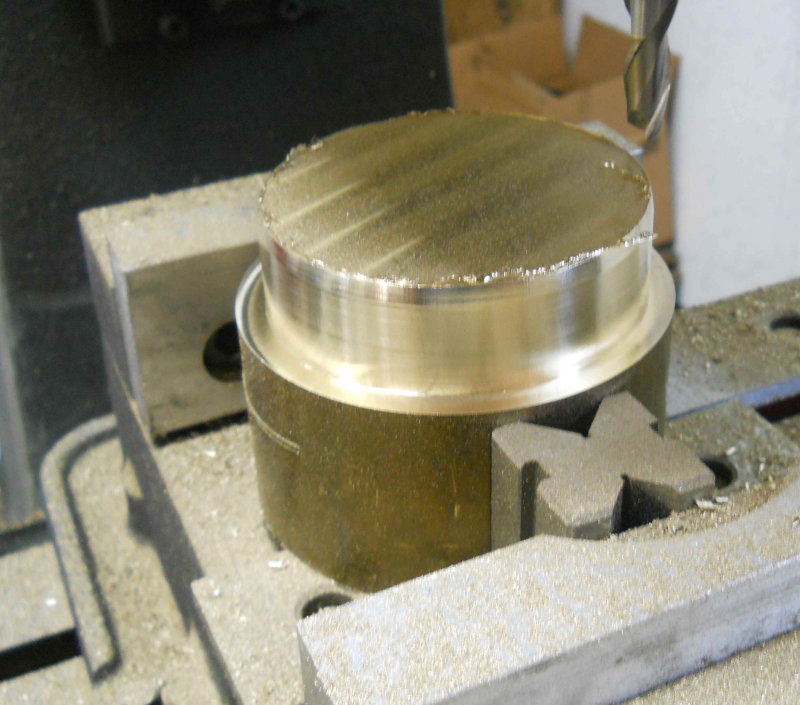

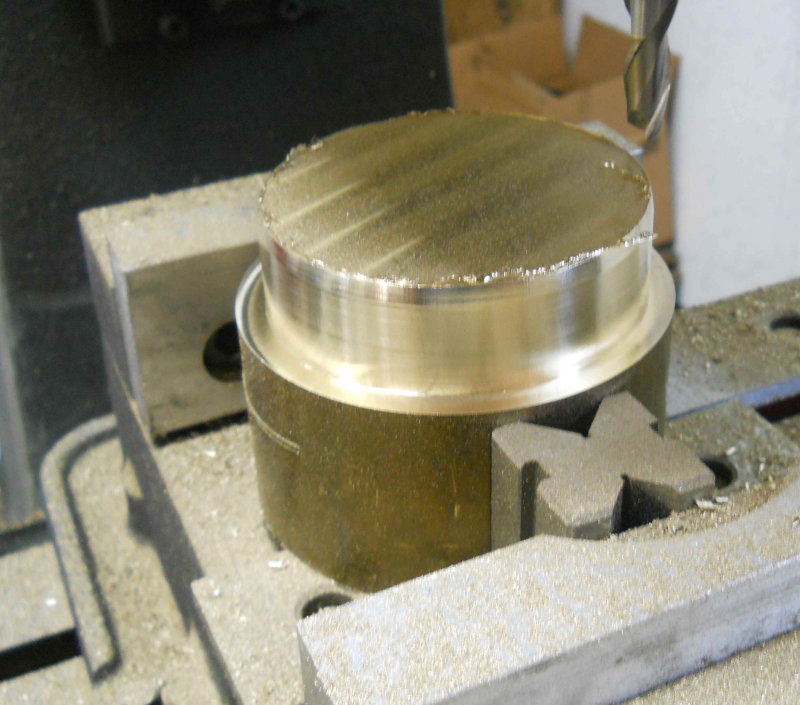

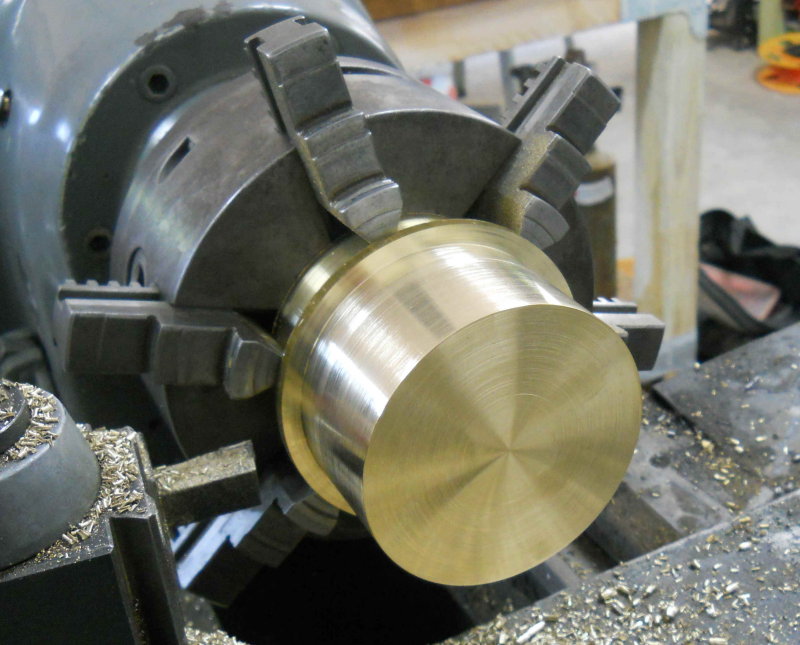

For a short shop session today, I made a start on the rear cylinder heads. These start as a 4" diameter drop of brass about 4" long that I bought at NAMES. I tried cutting it in two with the bandsaw, but couldn't get the blade to start straight, so another strategy was needed. After face milling both sides flat, I used the CNC mill to reduce the diameter to 3.5" for a length of 1". This meant that I could chuck it in the lathe.

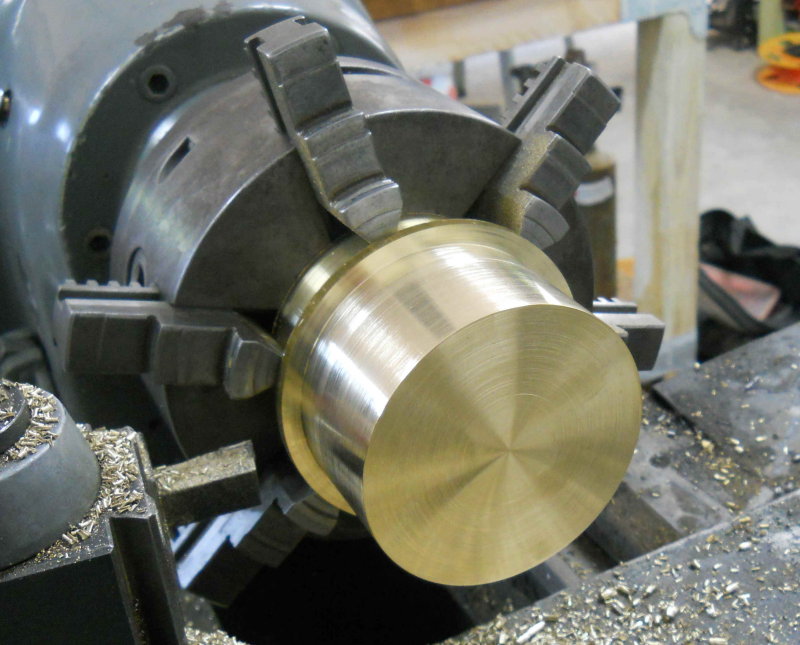

Now I could turn most of the rest down to 3.5", then face and turn the bore spigot for the first cylinder.

Then I needed to part off the first one. Using a 1/8" parting blade and the lathe in back gear at 200 rpm, I was able to get a pretty good cut. I started out with only 1/2" of blade exposed in the holder, and then successively extended it bit by bit. Once the outer slice started to wobble, I could just break it off by hand. Then I did machined the face and spigot for the second cylinder without needed to rechuck.

Since these are now 3.5" in diameter, I can use the same pockets in the soft jaws as for the front heads to continue machining.

Now I could turn most of the rest down to 3.5", then face and turn the bore spigot for the first cylinder.

Then I needed to part off the first one. Using a 1/8" parting blade and the lathe in back gear at 200 rpm, I was able to get a pretty good cut. I started out with only 1/2" of blade exposed in the holder, and then successively extended it bit by bit. Once the outer slice started to wobble, I could just break it off by hand. Then I did machined the face and spigot for the second cylinder without needed to rechuck.

Since these are now 3.5" in diameter, I can use the same pockets in the soft jaws as for the front heads to continue machining.

Re: Kozo A3 in 1.5" scale - new project

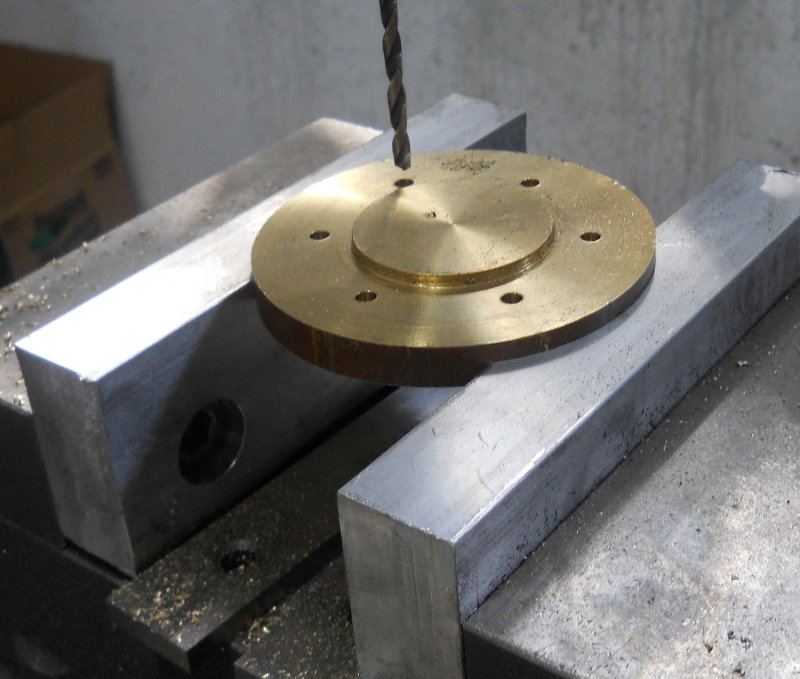

The next ops on the rear heads were to drill the mounting holes and then mill the final flange diameter.

Now I needed new pockets on the soft jaws.

Now the two spigots on the rear side of the head could be milled.

Then the through hole was drilled and reamed .380, and the bushing pocket was milled: .507 diameter, .782 deep using a 3/8 endmill.

There are still some ops needed on these parts for mounting the crosshead guides, but that will wait until I know the piston will move properly. So the next tasks will be to machine the bushings to fit the pocket, and then make the pistons. I already have the rings, so once it's all together will be the moment of truth.

Now I needed new pockets on the soft jaws.

Now the two spigots on the rear side of the head could be milled.

Then the through hole was drilled and reamed .380, and the bushing pocket was milled: .507 diameter, .782 deep using a 3/8 endmill.

There are still some ops needed on these parts for mounting the crosshead guides, but that will wait until I know the piston will move properly. So the next tasks will be to machine the bushings to fit the pocket, and then make the pistons. I already have the rings, so once it's all together will be the moment of truth.

Re: Kozo A3 in 1.5" scale - new project

The past few shop sessions were for making the pistons, parts that seem pretty simple looking at the plans but which took me a lot of time to realize. I started with a piece of 2.5" diameter CI rod left over from a previous project. There was "just" enough there to make the 6 pieces needed for two pistons, so some rechucking at the lathe was necessary.

First I turned the diameter down to the 1.745" called for in the plans, then drilled and reamed through.

After much difficulty and breaking my 1/16" parting tool twice, I got the pieces roughed out.

Lots of milling, drilling, reaming, counterboring and tapping later, the result:

I loctited the large pieces to the piston rods, then assembled using 5-40 screws. Now I could chuck the rod in a collet on the lathe and take a small turning cut to true all the diameters.

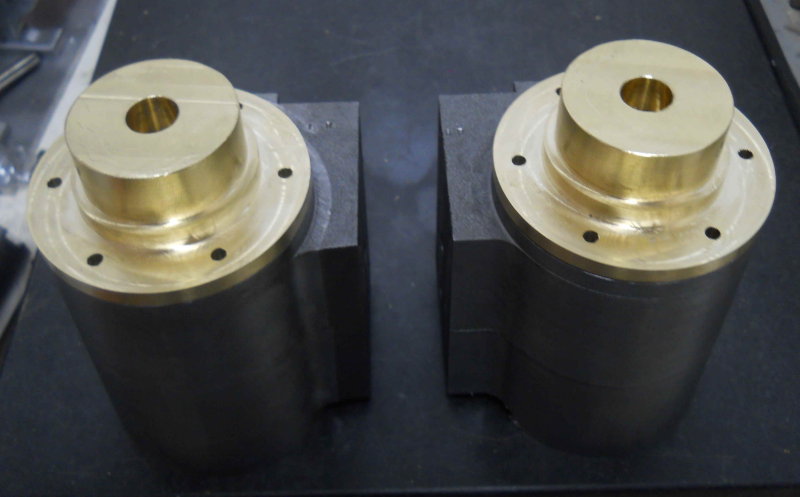

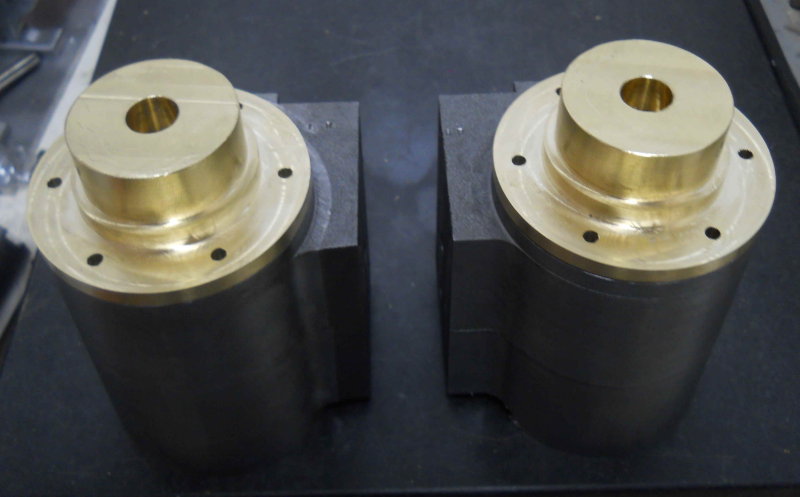

Then I turned the bushings from phosphor bronze and did a quick assembly with the cylinders.

The good news is that both pistons slide smoothly within the cylinder bore, although neither the rings nor the screws for the heads are in place. I have tested that the rings do fit well in the bore. However, the piston body needs enough clearance to account for expansion when running. This is needed since the piston will expand faster than the cylinder when steam is introduced. Kozo's plans call for .005" difference in the piston and bore diameters; based on the design however, I think the clearance can be a bit larger than that without harm.

While the green loctite 620 should be sufficient to fix the piston on its rod, I will also add the pin that Kozo specifies for extra security.

First I turned the diameter down to the 1.745" called for in the plans, then drilled and reamed through.

After much difficulty and breaking my 1/16" parting tool twice, I got the pieces roughed out.

Lots of milling, drilling, reaming, counterboring and tapping later, the result:

I loctited the large pieces to the piston rods, then assembled using 5-40 screws. Now I could chuck the rod in a collet on the lathe and take a small turning cut to true all the diameters.

Then I turned the bushings from phosphor bronze and did a quick assembly with the cylinders.

The good news is that both pistons slide smoothly within the cylinder bore, although neither the rings nor the screws for the heads are in place. I have tested that the rings do fit well in the bore. However, the piston body needs enough clearance to account for expansion when running. This is needed since the piston will expand faster than the cylinder when steam is introduced. Kozo's plans call for .005" difference in the piston and bore diameters; based on the design however, I think the clearance can be a bit larger than that without harm.

While the green loctite 620 should be sufficient to fix the piston on its rod, I will also add the pin that Kozo specifies for extra security.