Dayton Motor Rev/Fwd Wiring

Dayton Motor Rev/Fwd Wiring

Hi all, I'm a newby so bare with me please. I just bought a southbend model A (Cat 644A) 12 speed lathe. The motor was mounted but not connected. By looks of the drum switch, I think it was wired to a 3 phase motor previously. I need help connecting it properly for forward/reverse operation with the Dayton 1 phase motor it now has on it.

Here is what I have:

Dayton, Model 6K759, 3/4 HP, 115/230V, 1-Phase, 1725 RPM, Capacitor Start AC Motor, Furnas RSB5 Reversing Controller Drum Switch. Motor has the following wiring color configuration on the terminals: 1 (Line-in), 2 (Brown), 3 (White, Red, Orange), 4 (Yellow and Line-in), 5 (??? I don't see a #5 terminal), 6 (Brown). This config is shown on the motor plate (no #5 terminal) and I have also confirmed visually.

The motor reads: " To Reverse Rotation Interchange Blu with Wht and Yel with Org".

Please help with wiring... I have plenty of pics, motor wiring diagram, etc... I can send to anyone that is able to assist.

Thank You!!!

Here is what I have:

Dayton, Model 6K759, 3/4 HP, 115/230V, 1-Phase, 1725 RPM, Capacitor Start AC Motor, Furnas RSB5 Reversing Controller Drum Switch. Motor has the following wiring color configuration on the terminals: 1 (Line-in), 2 (Brown), 3 (White, Red, Orange), 4 (Yellow and Line-in), 5 (??? I don't see a #5 terminal), 6 (Brown). This config is shown on the motor plate (no #5 terminal) and I have also confirmed visually.

The motor reads: " To Reverse Rotation Interchange Blu with Wht and Yel with Org".

Please help with wiring... I have plenty of pics, motor wiring diagram, etc... I can send to anyone that is able to assist.

Thank You!!!

- swatson144

- Posts: 214

- Joined: Fri Sep 16, 2011 7:39 pm

- Location: SE Virginia

- Contact:

Re: Dayton Motor Rev/Fwd Wiring

In a nut shell you simply reverse the starter windings to reverse the motor. Since you are using a rotary switch you'd wire it to this end.

http://igor.chudov.com/manuals/ElectricMotors.pdf see if that helps.

Steve

http://igor.chudov.com/manuals/ElectricMotors.pdf see if that helps.

Steve

Re: Dayton Motor Rev/Fwd Wiring

Hi There,

one of the two start winding leads is hard wired inside the motor to terminal

#4. Therefore, the tag is indicating the reversal of the run windings (the Blu/Wht

pair and the Yel/Org pair).

Let me ask a question. Is this motor a 'thermally' or 'overload' protected motor?

If so, then I believe I understand what is going on inside this motor (electrically)

and I think I can help with the wiring of the drum switch.

What voltage are you planning to use (low or high)?

Good Luck!

-Blue Chips-

Webb

I don't think you can do that with this motor. If I'm correct (this is a big 'IF'),swatson144 wrote:In a nut shell you simply reverse the starter windings to reverse the motor. Since you are using a rotary switch you'd wire it to this end.

http://igor.chudov.com/manuals/ElectricMotors.pdf see if that helps.

Steve

one of the two start winding leads is hard wired inside the motor to terminal

#4. Therefore, the tag is indicating the reversal of the run windings (the Blu/Wht

pair and the Yel/Org pair).

Let me ask a question. Is this motor a 'thermally' or 'overload' protected motor?

If so, then I believe I understand what is going on inside this motor (electrically)

and I think I can help with the wiring of the drum switch.

What voltage are you planning to use (low or high)?

Good Luck!

-Blue Chips-

Webb

Re: Dayton Motor Rev/Fwd Wiring

wlw... Yes, the motor plate says its "Thermally Protected Auto". I believe your right about the internal hard wire. I have the schematic provided by grainger but noticed one terminal is not accessible. When I thought it through, it wasn't making sense to alternate only one start winding since two are shown in the motor schematic. Logically it makes sense to then alternate both main windings, but I can't figure out how to do that with the funky connection pattern of my drum switch. I'll buy another switch if I have to. I'll post the motor schematic from grainger later tonight when I get home.

Thx!

Thx!

Re: Dayton Motor Rev/Fwd Wiring

Hi There,

But, I need to know what voltage you are planning to use.

The 'funky' part is taking advantage of the thermal overload

protection built into the motor. By the way, I'm not a big fan

of 'Auto' reset motors used on lathes. The reason is that IF

the motor overloads and trips the device, the operator may

forget to turn off the lathe and after it cools down, the motor

resets and the lathe starts up by itself; not exactly the 'safest'

thing when dealing with potentially hazardous machinery. It

should be okay so long as one remembers to turn off the

machine after it 'trips' the thermal device.

Good Luck!

-Blue Chips-

Webb

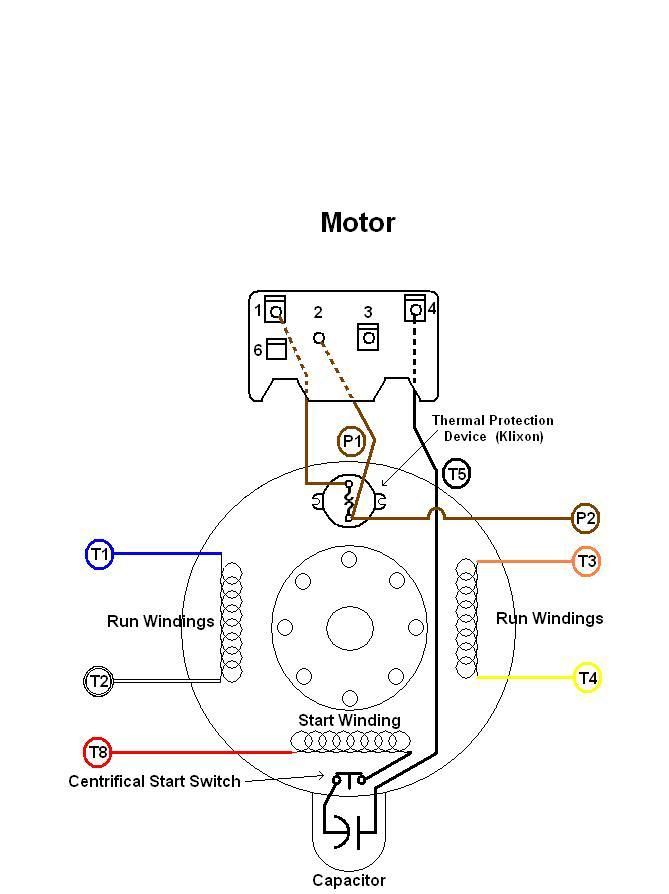

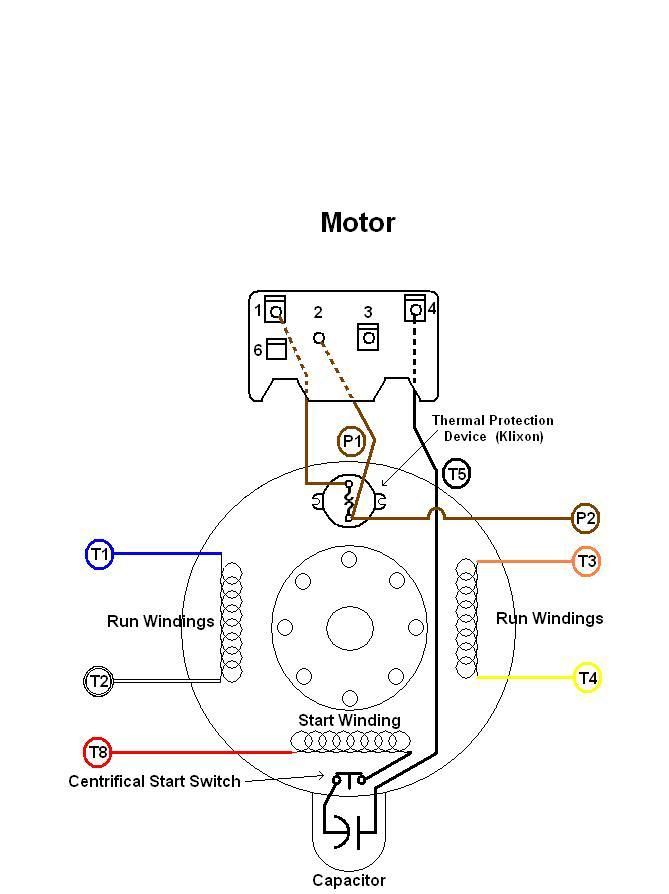

Edit: Here is a diagram of the motor (as I see it) showing the internal wiring:

That would be helpful but I should be able to help without it.race5050 wrote:wlw... Yes, the motor plate says its "Thermally Protected Auto". I believe your right about the internal hard wire. I have the schematic provided by grainger but noticed one terminal is not accessible. When I thought it through, it wasn't making sense to alternate only one start winding since two are shown in the motor schematic. Logically it makes sense to then alternate both main windings, but I can't figure out how to do that with the funky connection pattern of my drum switch. I'll buy another switch if I have to. I'll post the motor schematic from grainger later tonight when I get home.

Thx!

But, I need to know what voltage you are planning to use.

The 'funky' part is taking advantage of the thermal overload

protection built into the motor. By the way, I'm not a big fan

of 'Auto' reset motors used on lathes. The reason is that IF

the motor overloads and trips the device, the operator may

forget to turn off the lathe and after it cools down, the motor

resets and the lathe starts up by itself; not exactly the 'safest'

thing when dealing with potentially hazardous machinery. It

should be okay so long as one remembers to turn off the

machine after it 'trips' the thermal device.

Good Luck!

-Blue Chips-

Webb

Edit: Here is a diagram of the motor (as I see it) showing the internal wiring:

Re: Dayton Motor Rev/Fwd Wiring

Here is the wiring diagram. I also included the drum switch wiring diagram also provided by Grainger, but it has a different connection layout than my drum switch. I guess I'll buy it if I have to.

The motor is wired for 220V and that is what I will use. I have a 30A, 220V circuit that I will connect it to.

I made a mistake in my previous post. There is only one start winding, not two. I didn't have the diagram in front of me. What I meant to say was that if I only alternated the yellow/orange lines (i.e., not blue and white also), then polarity of the main windings would be wrong. I'll have to do both, or somehow find the black wire and alternate with red via the drum switch. I'll stop now... I getting confused.

Lastly, how do I show your message in my reply window to show I am responding to your comments?

Thanks for all your help!

The motor is wired for 220V and that is what I will use. I have a 30A, 220V circuit that I will connect it to.

I made a mistake in my previous post. There is only one start winding, not two. I didn't have the diagram in front of me. What I meant to say was that if I only alternated the yellow/orange lines (i.e., not blue and white also), then polarity of the main windings would be wrong. I'll have to do both, or somehow find the black wire and alternate with red via the drum switch. I'll stop now... I getting confused.

Lastly, how do I show your message in my reply window to show I am responding to your comments?

Thanks for all your help!

Re: Dayton Motor Rev/Fwd Wiring

Wow that's a nice diagram that you drew! What software? AutoCad?

Re: Dayton Motor Rev/Fwd Wiring

Thanks for that bit of information. I'll be careful if it ever trips. I'll make sure I turn off power to the motor. I really need to figure out how to get to that black wire. Seems like it would be easier to switch red and black.wlw-19958 wrote:Hi There,

That would be helpful but I should be able to help without it.race5050 wrote:wlw... Yes, the motor plate says its "Thermally Protected Auto". I believe your right about the internal hard wire. I have the schematic provided by grainger but noticed one terminal is not accessible. When I thought it through, it wasn't making sense to alternate only one start winding since two are shown in the motor schematic. Logically it makes sense to then alternate both main windings, but I can't figure out how to do that with the funky connection pattern of my drum switch. I'll buy another switch if I have to. I'll post the motor schematic from grainger later tonight when I get home.

Thx!

But, I need to know what voltage you are planning to use.

The 'funky' part is taking advantage of the thermal overload

protection built into the motor. By the way, I'm not a big fan

of 'Auto' reset motors used on lathes. The reason is that IF

the motor overloads and trips the device, the operator may

forget to turn off the lathe and after it cools down, the motor

resets and the lathe starts up by itself; not exactly the 'safest'

thing when dealing with potentially hazardous machinery. It

should be okay so long as one remembers to turn off the

machine after it 'trips' the thermal device.

Good Luck!

-Blue Chips-

Webb

Edit: Here is a diagram of the motor (as I see it) showing the internal wiring:

Re: Dayton Motor Rev/Fwd Wiring

Hi There,

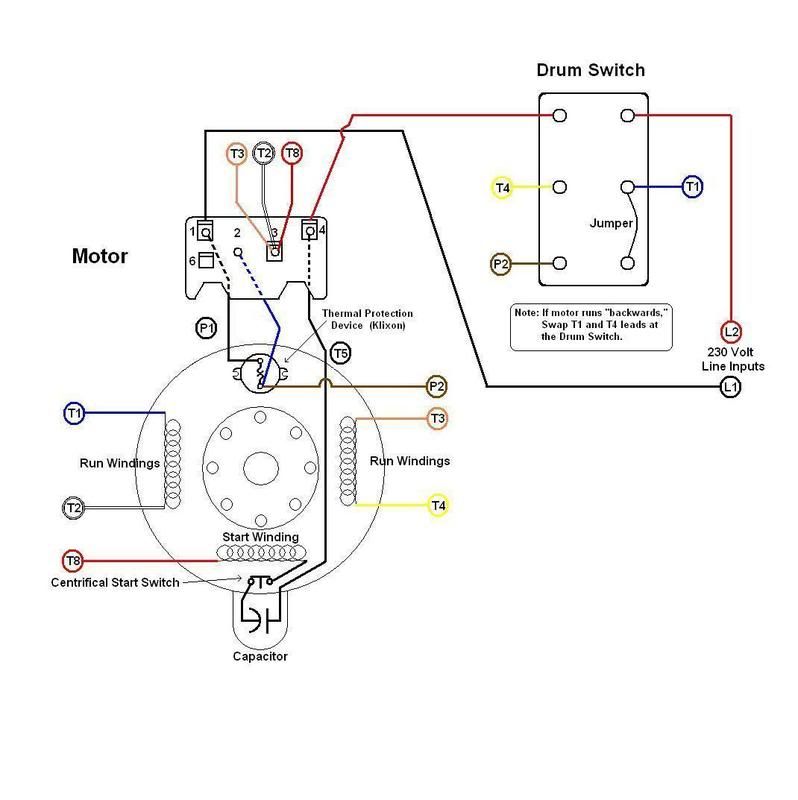

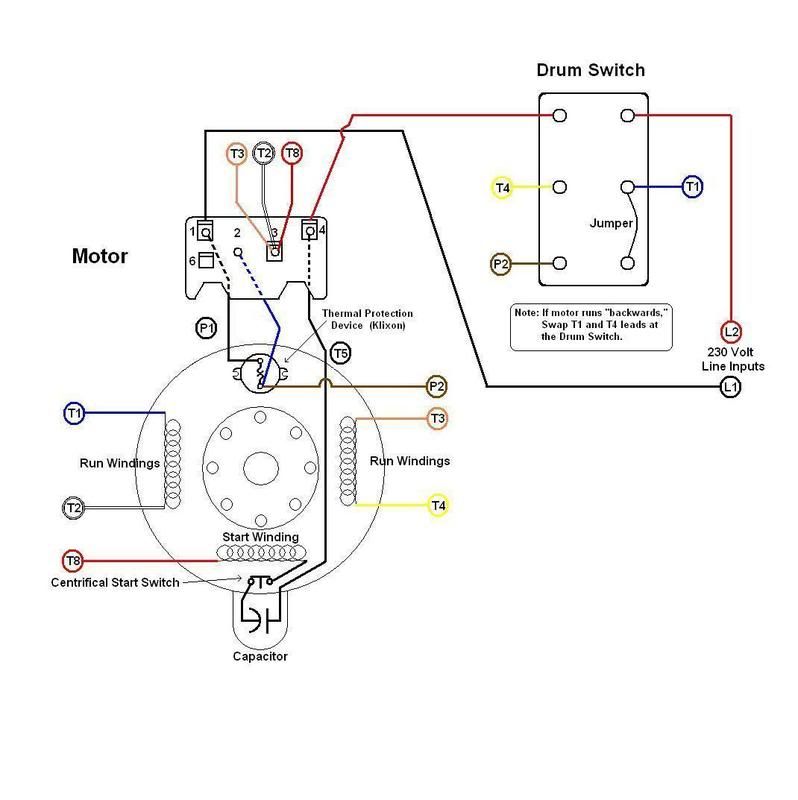

Okay, here is the wiring diagram. I made a few minor changes

based upon your supplemental information (color code change).

The drum switch info in your earlier post doesn't apply to your

particular drum switch.

Good Luck!

-Blue Chips-

Webb

Okay, here is the wiring diagram. I made a few minor changes

based upon your supplemental information (color code change).

The drum switch info in your earlier post doesn't apply to your

particular drum switch.

Good Luck!

-Blue Chips-

Webb

Re: Dayton Motor Rev/Fwd Wiring

Ok, I'll try that out. Can you elaborate regarding the drum switch? I can see the copper rotating terminal connections and I also confirmed with a continuity tester. From that, I drew up the hand drawn diagram.

Re: Dayton Motor Rev/Fwd Wiring

Hi There,

your later post doesn't have the same internal connections that

you supplied in your earlier post. Therefore, it is of little value

in your present situation. Your hand drawn diagram is fine and

I have configured my diagram based on it. The 'jumper' I illustrated

is the same one you illustrated in your diagram. I did this to

help with clarity regarding connections.

Is there anything else I can help explain to you?

Good Luck and Keep us Posted!

-Blue Chips-

Webb

Sure. The drum switch drawing supplied by W. W. Grainger inrace5050 wrote:Ok, I'll try that out. Can you elaborate regarding the drum switch? I can see the copper rotating terminal connections and I also confirmed with a continuity tester. From that, I drew up the hand drawn diagram.

your later post doesn't have the same internal connections that

you supplied in your earlier post. Therefore, it is of little value

in your present situation. Your hand drawn diagram is fine and

I have configured my diagram based on it. The 'jumper' I illustrated

is the same one you illustrated in your diagram. I did this to

help with clarity regarding connections.

Is there anything else I can help explain to you?

Good Luck and Keep us Posted!

-Blue Chips-

Webb

Re: Dayton Motor Rev/Fwd Wiring

No more explanation. Thank You soo much for your help. Hopefully I'll have time tonight to give it a test run. I'll post later with results. Then Once I get the machine going, I have to learn how to use it! LOL. First order will be to buy v-belt and a tool post since my lathe didn't come with either. Thanks Again!