Tailstock Turret

Tailstock Turret

In an effort to manufacture my small parts faster I am looking at ways to increase my speed. Are the tailstock turrets that are available from Grizzly (or the like) worth exploring? Are they accurate and rigid?

Any advice would be appreciated.

Any advice would be appreciated.

Last edited by RSG on Sun Oct 23, 2016 7:10 am, edited 1 time in total.

Vision is not seeing things as they are, but as they will be.

Re: Tool Post Turret

It's not clear to me what parts you hope to produce, but I'll relate my experience and you can use that as a guideline to see if you're on the right track.

I use a rather unusual indexing block, made by O.K. Rubber Welders. It's quite precise, and indexes in 3° increments. It has detents (spring loaded) @ 15° increments, so it's fast and easy to pick the desired location when indexing. There's an index plate with witness marks that permit indexing @3°, which is a little slower as it requires one to pay attention when locating the turret, which is moved by hand after being unlocked.

This system is much faster than the replaceable types of tool holders, but you are limited to the number of tools that can be used in a setup. You learn to make tools serve more than one purpose when necessary, and with some creativity you can often mount more than four tools, such as a small chamfering tool that doesn't require a heavy cut, as you often must use only one screw to hold the tool when more than four are installed.

The advantages of this type of tool post are of the greatest benefit when small parts are machined, where one indexes often. For larger work, where cuts last a long time, there isn't much to be gained by their use. Had I not specialized in small work, I'd have been far better off to use something like a KDK.

While I've posted a picture before, I'll provide one again for your perusal. It might interest you to know that the post shown is no longer available, although you might be successful in finding a used one. I recommend it highly---it's far better than any other indexing post I've used.

Harold

I use a rather unusual indexing block, made by O.K. Rubber Welders. It's quite precise, and indexes in 3° increments. It has detents (spring loaded) @ 15° increments, so it's fast and easy to pick the desired location when indexing. There's an index plate with witness marks that permit indexing @3°, which is a little slower as it requires one to pay attention when locating the turret, which is moved by hand after being unlocked.

This system is much faster than the replaceable types of tool holders, but you are limited to the number of tools that can be used in a setup. You learn to make tools serve more than one purpose when necessary, and with some creativity you can often mount more than four tools, such as a small chamfering tool that doesn't require a heavy cut, as you often must use only one screw to hold the tool when more than four are installed.

The advantages of this type of tool post are of the greatest benefit when small parts are machined, where one indexes often. For larger work, where cuts last a long time, there isn't much to be gained by their use. Had I not specialized in small work, I'd have been far better off to use something like a KDK.

While I've posted a picture before, I'll provide one again for your perusal. It might interest you to know that the post shown is no longer available, although you might be successful in finding a used one. I recommend it highly---it's far better than any other indexing post I've used.

Harold

Wise people talk because they have something to say. Fools talk because they have to say something.

-

Tom - AMS

- Posts: 18

- Joined: Thu Sep 10, 2015 1:02 am

- Location: Dallas-Fort Worth metro Texas

- Contact:

Re: Tool Post Turret

if your small parts are relatively short, consider setting up "gang tooling" on your cross slide. Its fast and rigid.

We do this often. For turning we use relatively large diameter but stubby boring bars ( or rigidity; they're easy to mach)

If we need to turn a lot off, to make a "stepped" part, we make/use a box tool and machine the part in one pass.

gang tooling can be as simple or complex as you want to make it - this link will give you some ideas:

www.omni-turn.com/Media/PDFs/Tooling%20catalog.pdf

We do this often. For turning we use relatively large diameter but stubby boring bars ( or rigidity; they're easy to mach)

If we need to turn a lot off, to make a "stepped" part, we make/use a box tool and machine the part in one pass.

gang tooling can be as simple or complex as you want to make it - this link will give you some ideas:

www.omni-turn.com/Media/PDFs/Tooling%20catalog.pdf

Re: Tailstock Turret

My apologies guys, I have no clue what I was thinking when I posted this. I meant Tailstock turret and corrected my post as such.

Vision is not seeing things as they are, but as they will be.

Re: Tailstock Turret

Tool length become a significant issue when using a tailstock turret, as you will be winding the quill in and out constantly. Moving the tailstock doesn't work that well either as you can loose your index.

A bed turret is the ticket!

A bed turret is the ticket!

Glenn

Operating machines is perfectly safe......until you forget how dangerous it really is!

Operating machines is perfectly safe......until you forget how dangerous it really is!

Re: Tailstock Turret

2nd the gang tooling on the cross slide if you have short parts w/small diameters.

The tool bar can have its own quick indexing so the lead screw doesn't need to travel much.

A well designed mount gains rigidity vs. the compound.

Don't forget rear mounted posts.

The tool bar can have its own quick indexing so the lead screw doesn't need to travel much.

A well designed mount gains rigidity vs. the compound.

Don't forget rear mounted posts.

Re: Tailstock Turret

Yes, as long as you don't much need your normal tail stock. I had one on my 11" Rockwell, and really liked it, though I never really did work to justify it's setup other than common tools. Fortunately, I had the 36/37" (depending on reference) bed, so most of the time I just left it hanging out on the extreme right. My mill was just to the right of the lathe. If I wanted the turret for something, I could position the mill table, slide the turret off (oh WOW it was heavy) right to the mill table. Then slide the tail stock off and set aside, realign the mill table and slide the turret onto the ways, position, adjust, set tools, and play with the turret. And play is the right term. Mostly it just sat on the end of the lathe, too much trouble to rotate into use.GlennW wrote:A bed turret is the ticket!

If I had another for the current 17" lathe, it would be vastly beyond my physical ability, so would have to be managed with the "sky-hook" like the chucks, and even more unlikely to see actual use. I know it's a sickness, but I still want one, because one day ...

Russ

Master Floor Sweeper

Master Floor Sweeper

Re: Tailstock Turret

A lot depends on the work you do on your lathe.

I bought my lathe (14 x 40)in 2007 and the bed turret a month or so after the lathe.

I remember a "machinist" that a friend brought with him seeing the turret on a pallet just after I bought it and saying "boy, that's a big waste of money right there for something you'll probably never use".

I think I have used the tailstock in place of the turret maybe half a dozen times now.

I recently drew up a locking plate for the tail stock that will allow me to set the tailstock onto the bed ways without having to remove the turret to slide it onto the ways from the end. The turret is well over one 100 pounds, but it's like trying to pick up a 100 pound octopus.

I bought my lathe (14 x 40)in 2007 and the bed turret a month or so after the lathe.

I remember a "machinist" that a friend brought with him seeing the turret on a pallet just after I bought it and saying "boy, that's a big waste of money right there for something you'll probably never use".

I think I have used the tailstock in place of the turret maybe half a dozen times now.

I recently drew up a locking plate for the tail stock that will allow me to set the tailstock onto the bed ways without having to remove the turret to slide it onto the ways from the end. The turret is well over one 100 pounds, but it's like trying to pick up a 100 pound octopus.

Glenn

Operating machines is perfectly safe......until you forget how dangerous it really is!

Operating machines is perfectly safe......until you forget how dangerous it really is!

Re: Tailstock Turret

Thanks for the idea! I just watched a few YouTube vids and they are exactly what I need. trouble is I'll have to build one myself as I don't see anything for sale anywhere.GlennW wrote:A bed turret is the ticket!

Vision is not seeing things as they are, but as they will be.

Re: Tailstock Turret

Can you post a link to the one you need? I'm confused, sorry.

Re: Tailstock Turret

I got extremely lucky and saw a classified ad on the web for mine and bought it. It was new and appears to have been custom built for my lathe. Don over on Practical machinist had it as he is in the used machinery sales business. I think it was like two ships colliding in the night, as he was the only one with a bed turret for a Nardini 1440, and I was the only one looking for one!(I should have bought a Lottery ticket as well)

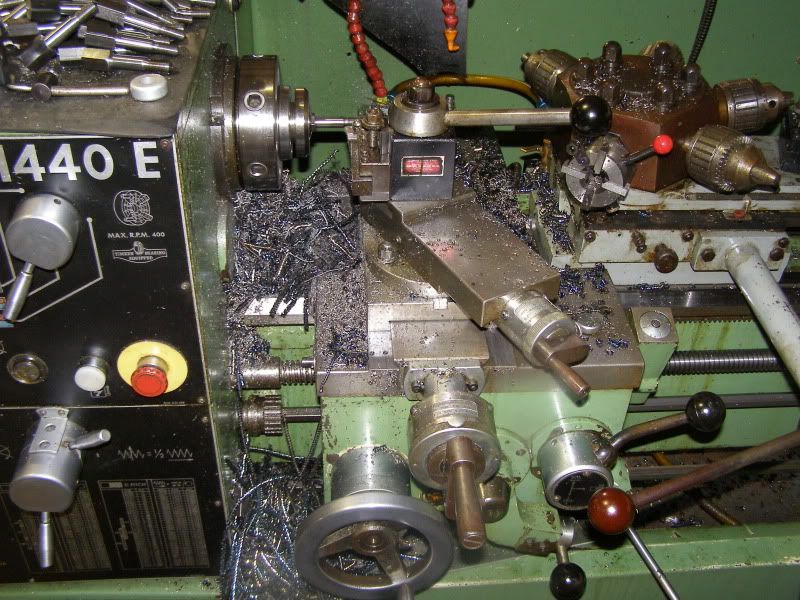

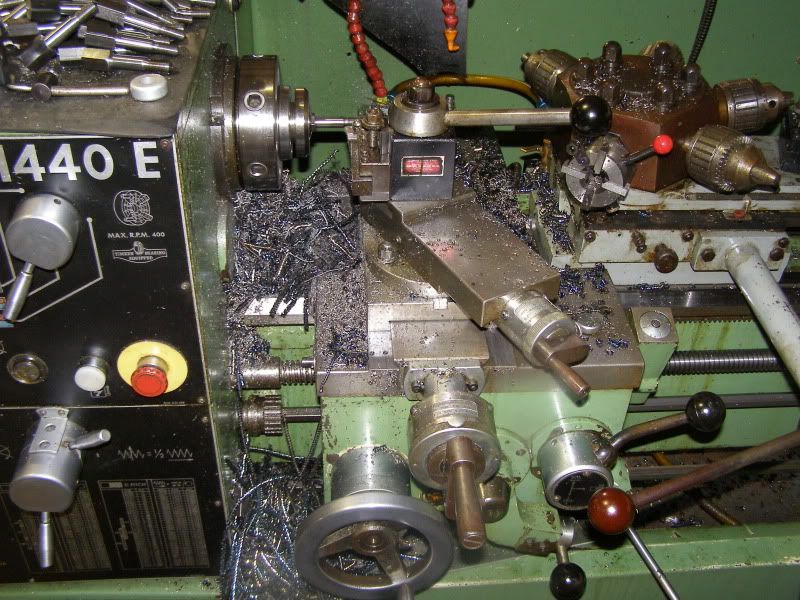

A bit messy, but I was in the middle of a 100 piece run of steel parts when this was taken. (Strangely enough, I'm in the middle of the same job again right now)

I keep it loaded with a work stop, four Jacobs chucks, and a die head.

A bit messy, but I was in the middle of a 100 piece run of steel parts when this was taken. (Strangely enough, I'm in the middle of the same job again right now)

I keep it loaded with a work stop, four Jacobs chucks, and a die head.

Glenn

Operating machines is perfectly safe......until you forget how dangerous it really is!

Operating machines is perfectly safe......until you forget how dangerous it really is!

Re: Tailstock Turret

Very cool Glenn!

I would like to build one.....some day I guess considering how busy I am at the moment it will be a ways off.

I would like to build one.....some day I guess considering how busy I am at the moment it will be a ways off.

Vision is not seeing things as they are, but as they will be.