The Final Chapter,

The nut carrier was and is the most difficult part of this vise. It started as 2" round and finished as a mess. The acme nut is round and was purchased from McMaster Carr along with the lead screw. It has two 1/4" bosses on each side that rides in two slots in the ways towers and is designed to pull up against the top of the slot to hold down the movable jaw when tightening.

The dovetail rides in the movable jaw dovetail to apply the downward force when clamping. The slight rise I currently have in the jaw is due to the height of the nut carrier dovetail. I will shorten the height to help keep the jaw down.

To lower the dovetail, I will machine off the height and to keep the same profile, I will narrow the neck. I have not done that yet, as the vise is working quite well as is.

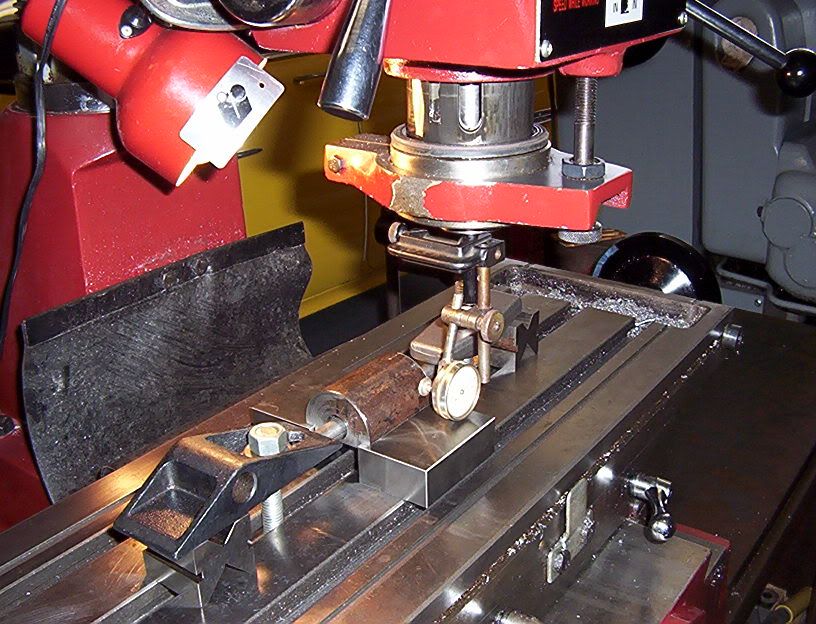

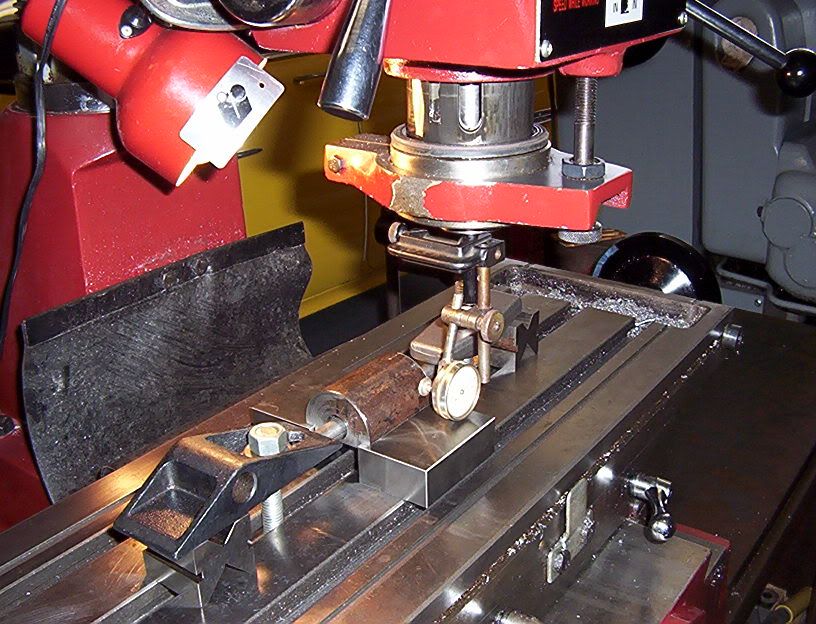

Without a good vise, I had to hold the part anyway I could. Drilled the hole first, then machined the flat top, then turned it over and rested it on two 123 blocks with a 5/8 bar through it. Best I could think of.

The brass nut is held in with three "dog end" set screws. The nut above the carrier rides in the relief machined into the movable jaw. To assemble the unit, the movable jaw and nut carrier are assembled, the set screw in the jaw is moved in to hold them together. Then with the fixed jaw removed, the unit is slid into the way slots and the lead screw is turned bringing the unit into the vise. When it is on, the fixed jaw is re-assembled.

Voile, a mill vise.

Its been fun and challenging, but maybe what I learned means I won't have to do another. Its like child birth I think, after the pain is gone, I will forget and build another.

Frank