I have ordered a Grizzly 9729 and I am in the midst of building the table/stand for it.

Does anyone have the distance between the bolt holes on the feet?

I am welding in supports under the top of the table.

Thanks

Jim

Grizzly 9729

Moderator: Harold_V

Grizzly 9729

Living in the Maritimes

Building a new Brewery and team

Driving a 65 Cobra up the Fundy coast

Dosen't get much better!

Building a new Brewery and team

Driving a 65 Cobra up the Fundy coast

Dosen't get much better!

Re: Grizzly 9729

Hello,

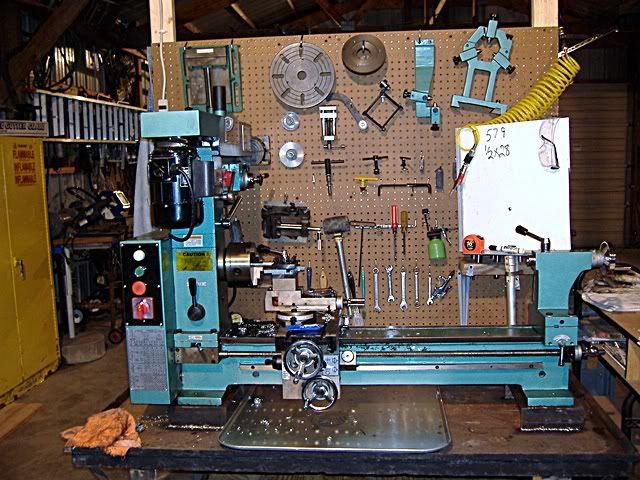

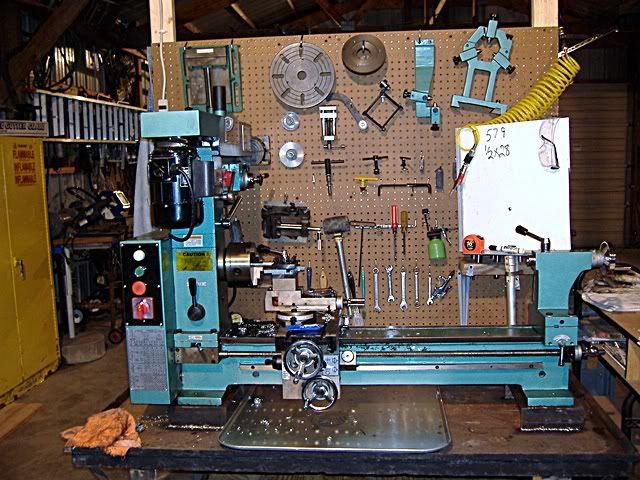

i will share the stand that i built for mine

it is 36X60X20 on the 6 inch casters it sets at 26.5 inches high .

the specs you asked for drilling your 1/2 inch bolt holes are

41 5/16 length and width is 5 3/4

you will need to run a tap through your holes as they should have paint

in them mine did . if you have any other questions post back i will check back to see if i can answer any other questions . my small shop is 1/4 of a 24X36 metal building i also have a HF 5980 3in 1 machine i do all kinds of small projects from firearms to making parts for 4wheelers .

i know you asked about this in 09 but i replied for others that may have the same questions .

JJ39

i will share the stand that i built for mine

it is 36X60X20 on the 6 inch casters it sets at 26.5 inches high .

the specs you asked for drilling your 1/2 inch bolt holes are

41 5/16 length and width is 5 3/4

you will need to run a tap through your holes as they should have paint

in them mine did . if you have any other questions post back i will check back to see if i can answer any other questions . my small shop is 1/4 of a 24X36 metal building i also have a HF 5980 3in 1 machine i do all kinds of small projects from firearms to making parts for 4wheelers .

i know you asked about this in 09 but i replied for others that may have the same questions .

JJ39

cobra wrote:I have ordered a Grizzly 9729 and I am in the midst of building the table/stand for it.

Does anyone have the distance between the bolt holes on the feet?

I am welding in supports under the top of the table.

Thanks

Jim