New B2229/G9729 Owner

Moderator: Harold_V

New B2229/G9729 Owner

I recently purchased a Craftex B2229, which appears to be a copy of a Grizzly G9729. So far I'm pleased with it, although I'm quite inexperienced so my opinion shouldn't carry much weight. I have run into one problem so far: one of the gibs came loose, and I can't seem to locate the set screw (if any) that's supposed to secure it (see photo). Can anyone tell me how it's supposed to be held in place?

I also have the stand that Busy Bee sells with the machine, which I see from some other threads is generally regarded as junk. I pretty much concur, but I replaced the feet with angle iron and casters (see other photo) and secured the stand to the wall of my shop for stability. That seems to work pretty well. (The jack is temporary, of course.)

Re: New B2229/G9729 Owner

ealanm,

You will probably have to take it apart and first find the set screw so it won't do anymore

damage. Clean and lube everything and put it back together and readjust where needed.

There was a guy on another forum called (Dutch_Metal13) that had a B2229 like yours and

if I remember, he had to readjust and tighten his up as well.

Ken.

You will probably have to take it apart and first find the set screw so it won't do anymore

damage. Clean and lube everything and put it back together and readjust where needed.

There was a guy on another forum called (Dutch_Metal13) that had a B2229 like yours and

if I remember, he had to readjust and tighten his up as well.

Ken.

One must remember.

The best learning experiences come

from working with the older Masters.

Ken.

The best learning experiences come

from working with the older Masters.

Ken.

Re: New B2229/G9729 Owner

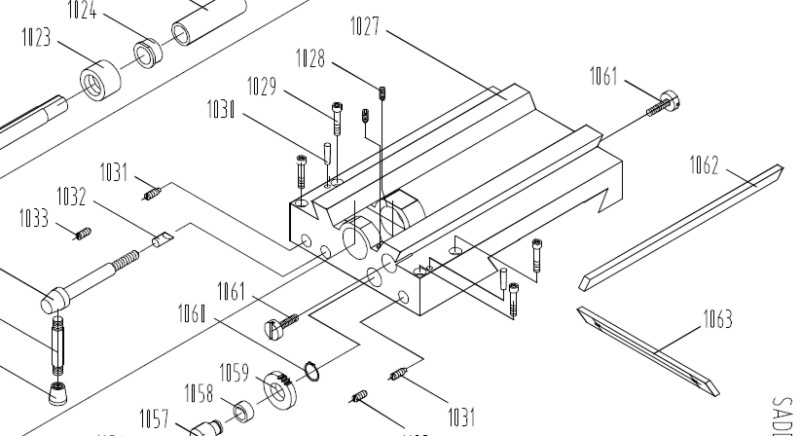

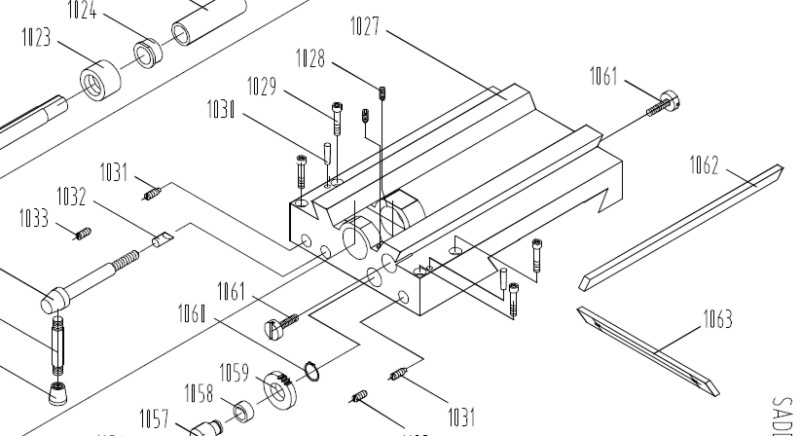

There is no set screw, per se. That is a tapered gib -- it is adjusted by sliding it in and out. There should be a pair of adjustment screws -- one at either end -- that are adjusted as a pair. I think the heads actually engage in a slot in the underside of the gib. The screws are #1061 and the gib is #1062 in this image:

Re: New B2229/G9729 Owner

Torch:

Thanks! I looked at that drawing but didn't pick up on the significance of those screws. I'm still not quite seeing how they work, but at least I know where they are now, so I should be able to figure it out.

Tedd

Thanks! I looked at that drawing but didn't pick up on the significance of those screws. I'm still not quite seeing how they work, but at least I know where they are now, so I should be able to figure it out.

Tedd

Re: New B2229/G9729 Owner

The screw threads into the carriage. The bore for the head of the screw is large enough that it overlaps the inside of the dovetail slightly, forming that groove shown on the end of the dovetail. The notch in the bottom of the gib, visible in your photo, captures the head of the screw so that the gib is slid along the dovetail by the heads of the screws (one at each end so there is no play). The gib thickness is ground to a taper from end to end and the dovetail has a corresponding but opposite taper -- like two wedges opposing each other. So, as the gib is slid rearwards, the tapers interact to force the gib outwards and eliminate the play between the carriage and the table. Both screws must be adjusted simultaneously, one being loosened as the other is tightened.ealanm wrote:Torch:

Thanks! I looked at that drawing but didn't pick up on the significance of those screws. I'm still not quite seeing how they work, but at least I know where they are now, so I should be able to figure it out.

Clear as mud?

Re: New B2229/G9729 Owner

Here's a picture of the installed gib screw:

Re: New B2229/G9729 Owner

Got it! Thanks very much for the explanation.