Replacement motor for Riding Railkits diesel

Moderator: Harold_V

Replacement motor for Riding Railkits diesel

Hi all, my son has a Riding Railkits 1" diesel that uses a 24-volt, 2255-rpm, 7.38-amp electric motor made by the company RAE. The motor is acting up; we've cleaned it inside and out and replaced the brushes, but it seems as though something is still hitting as it rotates. The bearings look good, so we're now taking a closer look at anything else that would be binding (one of the pockets for the brushes looks a little suspect).

At the same time, if we can't manage to fix it I'm beginning to think about a possible replacement. RAE says this motor was a custom order for Riding Railkits, and RAE doesn't stock replacements. I don't know yet if Riding Railkits specifically has more motors, but their inventory in general has been greatly reduced this year with many discontinued items, so it seems somewhat unlikely.

Can any suggest any other motors out there that would be close to the above specs that we might consider going to as an alternative?

At the same time, if we can't manage to fix it I'm beginning to think about a possible replacement. RAE says this motor was a custom order for Riding Railkits, and RAE doesn't stock replacements. I don't know yet if Riding Railkits specifically has more motors, but their inventory in general has been greatly reduced this year with many discontinued items, so it seems somewhat unlikely.

Can any suggest any other motors out there that would be close to the above specs that we might consider going to as an alternative?

- steamin10

- Posts: 6712

- Joined: Sun Jun 08, 2003 11:52 pm

- Location: NW Indiana. Close to Lake Michigan S. tip

IMHO check with riding rails first, and see what kind of answere you get before you start combing the countryside..

Otherwise motors of similar size and stature will work. Several builders of small permag motors will custom build you a repacement. David Sclavi commented on such a while back.

Otherwise motors of similar size and stature will work. Several builders of small permag motors will custom build you a repacement. David Sclavi commented on such a while back.

Big Dave, former Millwright, Electrician, Environmental conditioning, and back yard Fixxit guy. Now retired, persuing boats, trains, and broken relics.

We have enough youth, how about a fountain of Smart. My computer beat me at chess, but not kickboxing

It is not getting caught in the rain, its learning to dance in it. People saying good morning, should have to prove it.

We have enough youth, how about a fountain of Smart. My computer beat me at chess, but not kickboxing

It is not getting caught in the rain, its learning to dance in it. People saying good morning, should have to prove it.

Thanks for the comments. Good point about the motor's magnets attracting ferrous metals -- we've taken it apart pretty thoroughly, though, and don't see anything. The one thing I notice is that the sleeve for one of the brushes seems to be in a slightly different position than the other.

We'll keep tinkering with it, but will look around for a local shop (Los Angeles area) to try taking it to for repair. We also might try fitting something like a scooter motor to see if we can make it work. If anyone has any particular motors they like or think would be suited for this, I'd be interested to hear about it.

We'll keep tinkering with it, but will look around for a local shop (Los Angeles area) to try taking it to for repair. We also might try fitting something like a scooter motor to see if we can make it work. If anyone has any particular motors they like or think would be suited for this, I'd be interested to hear about it.

Update: We seem to have the motor fixed now, at least well enough for my son to run at Los Angeles Live Steamers' Small Scale Sunday tomorrow. I never did put my finger on exactly what the issue was. The tolerances seem fairly close, so assembly factors like tightening the motor case screw on one side tighter than the other side would cause it to produce excess noise.

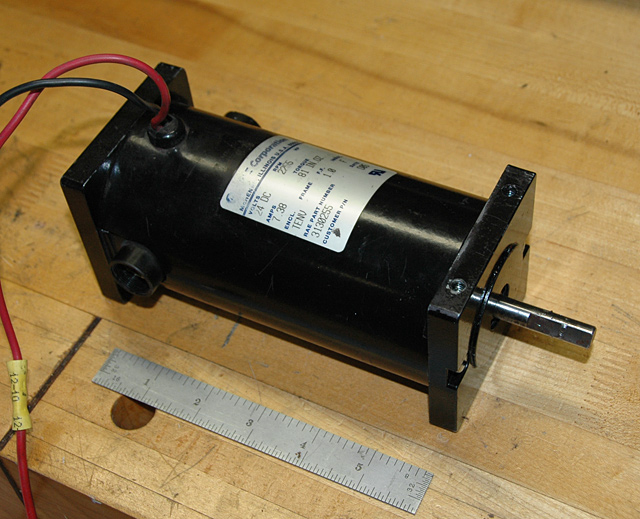

Just to have a backup option, we ordered a 24-volt scooter motor off eBay to test with the loco. The mounting holes are completely different, so we'll have to fabricate an adapter bracket, and probably a new chain (though one plus is that the new motor comes with a sprocket for the same size of chain that's currently on the loco). The new motor also appears to be considerably more powerful than the old one -- its maximum current draw is about 2x what we have now. So my son will probably be able to pull more cars (if, that is, wheel slippage weren't an issue -- but I have to suspect that it will be).

Just to have a backup option, we ordered a 24-volt scooter motor off eBay to test with the loco. The mounting holes are completely different, so we'll have to fabricate an adapter bracket, and probably a new chain (though one plus is that the new motor comes with a sprocket for the same size of chain that's currently on the loco). The new motor also appears to be considerably more powerful than the old one -- its maximum current draw is about 2x what we have now. So my son will probably be able to pull more cars (if, that is, wheel slippage weren't an issue -- but I have to suspect that it will be).

Suspect in what way?one of the pockets for the brushes looks a little suspect

When you disassembled this motor did you match mark the end plate? It affects how the brushes align with the magnetic poles. There may be a mark from the factory.

You can't count on the motor bolts to make this alignment. Though you can sometimes tune the motor while running on the bench with the bolts lightly snugged.

This site has a great deal of information about trouble shooting and correcting DC motor problems.

http://www.morganhungary.hu/technicalsupport/patina.htm

And yes the bolts should be tightened evenly.

Thanks, good point about marking the end plates. In this case, each had threaded holes for mounting screws, which also served to show the required assembly orientation.

The thing about the brush pockets: One of them was entirely rectagular in profile, while the other was very slightly concave with a very slight lip, which suggested to me that the pocket and not just the brush itself was hitting the armature. Seems to be okay now.

Great info at the morganhungary.hu site! I'll be bookmarking that one.

The thing about the brush pockets: One of them was entirely rectagular in profile, while the other was very slightly concave with a very slight lip, which suggested to me that the pocket and not just the brush itself was hitting the armature. Seems to be okay now.

Great info at the morganhungary.hu site! I'll be bookmarking that one.