How Would I Bevel a 6" Piece of 1/8" x 1" Bar Stock Across Its Length?

Re: How Would I Bevel a 6" Piece of 1/8" x 1" Bar Stock Across Its Length?

Well, unfortunately the shim was destroyed when drilling the hole though the thin end when the bit grabbed the material and twisted it around.

- Bill Shields

- Posts: 10560

- Joined: Fri Dec 21, 2007 4:57 am

- Location: 39.367, -75.765

- Contact:

Re: How Would I Bevel a 6" Piece of 1/8" x 1" Bar Stock Across Its Length?

I was going to suggest:

surface grinder with a magnetic chuck shimmed up at the required angle..

but since you are there...

surface grinder with a magnetic chuck shimmed up at the required angle..

but since you are there...

Too many things going on to bother listing them.

Re: How Would I Bevel a 6" Piece of 1/8" x 1" Bar Stock Across Its Length?

I made another out of 1/8" think aluminum this afternoon, though I still haven't drilled it. I used the same technique as before except that this piece was longer than necessary, so I could cut off, rather than grind down, where the ends were attached during milling. That saved a whole lot of time and it came out better than the first made of strap iron.

- warmstrong1955

- Posts: 3568

- Joined: Thu Mar 18, 2010 2:05 pm

- Location: Northern Nevada

Re: How Would I Bevel a 6" Piece of 1/8" x 1" Bar Stock Across Its Length?

Little late now, but maybe you should have drilled before you milled on the aluminum one......

You could regrind the rake of the drill bit. Doesn't take much to keep it from grabbing.

I have drilled thin parts using an end-mill. They don't grab much as a regular drill bit. Not the prescribed use for end-mills....but it works.

Bill

You could regrind the rake of the drill bit. Doesn't take much to keep it from grabbing.

I have drilled thin parts using an end-mill. They don't grab much as a regular drill bit. Not the prescribed use for end-mills....but it works.

Bill

Today's solutions are tomorrow's problems.

Re: How Would I Bevel a 6" Piece of 1/8" x 1" Bar Stock Across Its Length?

No, because the back edge is curved to match the bracket it goes under and if I predrilled it then milled it, I probably coudn't get this curved edge to align perfectly. Once the metal is thin, it is a simple matter to match the back edge with the sander.

Next time I will secure both pieces to a wooden surface to compress then together (or such) before drilling them rather than trust the jaws of the vise to hold them together in alignment.

Next time I will secure both pieces to a wooden surface to compress then together (or such) before drilling them rather than trust the jaws of the vise to hold them together in alignment.

- liveaboard

- Posts: 1982

- Joined: Sun Dec 08, 2013 1:40 pm

- Location: southern Portugal

- Contact:

Re: How Would I Bevel a 6" Piece of 1/8" x 1" Bar Stock Across Its Length?

You have a milling machine but no welding gear??

You're doing an impressive lot of machine work to solve a problem with a simple defective steel bracket.

Anyway, anything is good if it does the job.

You're doing an impressive lot of machine work to solve a problem with a simple defective steel bracket.

Anyway, anything is good if it does the job.

Re: How Would I Bevel a 6" Piece of 1/8" x 1" Bar Stock Across Its Length?

I don't think it is a matter of a defective bracket so much as compensating for a misalignment of the existing parts.

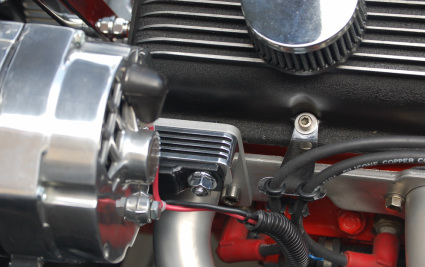

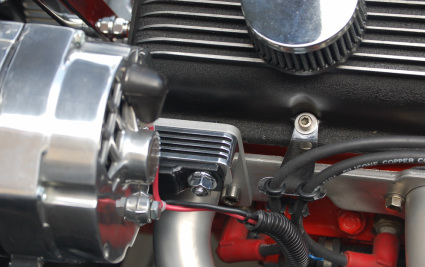

The alternator seems to have a bit of an inward cant because the surface that it mounts to (the header's flange) has a bit of an inward cant rather than being parallel with the centerline of the engine. If I hold a straight edge along this surface, it seems a bit further from tht rear of the engine than the front.

This goes between the black bracket that mounts the alternator and the polished aluminum ribbed spacer. Ordinarily a slight misalignment is not a problem for a belt that sits within the deep groove of a pulley. But this is a Gilmer system and is much less forgiving as the belt can walk forward or rearward depending on the angle of the alternator.

The alternator seems to have a bit of an inward cant because the surface that it mounts to (the header's flange) has a bit of an inward cant rather than being parallel with the centerline of the engine. If I hold a straight edge along this surface, it seems a bit further from tht rear of the engine than the front.

This goes between the black bracket that mounts the alternator and the polished aluminum ribbed spacer. Ordinarily a slight misalignment is not a problem for a belt that sits within the deep groove of a pulley. But this is a Gilmer system and is much less forgiving as the belt can walk forward or rearward depending on the angle of the alternator.

Re: How Would I Bevel a 6" Piece of 1/8" x 1" Bar Stock Across Its Length?

I made a jig of wood to hold the two pieces in alignment for drilling in the press and the holes came out perfect.

I test mounted it and it is hardly visible. The angle is so gentle that I really don't need to worry about the alignment of the bolt heads/nuts.

I test mounted it and it is hardly visible. The angle is so gentle that I really don't need to worry about the alignment of the bolt heads/nuts.