New member from Houston TX

Thanks for your comments, Charles. I am a bit surprised at the reg's he faces in Houston, however.

I not only wired my own shop and house, but installed the services as well, including the CT can and meter bases. Shop has three phase 240 volt service.

I can only shake my head and wonder how much it would have cost me to have had it done by the pro's!

Harold

I not only wired my own shop and house, but installed the services as well, including the CT can and meter bases. Shop has three phase 240 volt service.

I can only shake my head and wonder how much it would have cost me to have had it done by the pro's!

Harold

Harold,

We use Means Construction Cost for setting up initial budgeting here and if your curious the following would be a good budget

Meter box install $800.00 including utility inspection and red tag

Main bus install with breakers 200 amp service, 60 amp HVAC, 40 amp mill, 30 amp lathe, 20 amp lights (2) 20 amp outlets, 30 amp welder , 60 amp compressor cost $3,200.00

You are talking about a minimum of $4,000.00 and the material costs are on $1,100.00

All of this assumes exposed framing if retrofitting or using conduits that would add an addition $2,700.00

We use Means Construction Cost for setting up initial budgeting here and if your curious the following would be a good budget

Meter box install $800.00 including utility inspection and red tag

Main bus install with breakers 200 amp service, 60 amp HVAC, 40 amp mill, 30 amp lathe, 20 amp lights (2) 20 amp outlets, 30 amp welder , 60 amp compressor cost $3,200.00

You are talking about a minimum of $4,000.00 and the material costs are on $1,100.00

All of this assumes exposed framing if retrofitting or using conduits that would add an addition $2,700.00

The best times were behind one of Al's engines

Most of Texas large cities have similar restrictions. IIRC, if you read the city code a certain way in Fort Worth, technically you can't change a light switch. When we had major rework done on our house there in 1982, I had already rewired the garage. They city inspector that came to look at the house upgrade looked at the garage and said "You can't do that - period. However, it's done well and I'm going to leave it if the master on site says he doesn't have a problem with it." The alternative would have been that he'd have ordered it all torn out. Houston is as bod or maybe worse because for so long they let whatever go. You can drive down roads and see commercial buildings next to houses, next to a horse barn, etc.Harold_V wrote:Thanks for your comments, Charles. I am a bit surprised at the reg's he faces in Houston, however.

I not only wired my own shop and house, but installed the services as well, including the CT can and meter bases. Shop has three phase 240 volt service.

I can only shake my head and wonder how much it would have cost me to have had it done by the pro's!

Harold

He's in Clear Lake, down by the LBJ Space Center so I'm not sure what local codes apply - they may just use Houston's code. There is a LOT of "Houston" population that is not in the real live city limits.

Chris -

http://raceabilene.com/kelly/hotrod

"Check all parts for proper condition before operation; if normal safety precautions are noticed carefully, this machine can provide you withstanding of accurate service."

http://raceabilene.com/kelly/hotrod

"Check all parts for proper condition before operation; if normal safety precautions are noticed carefully, this machine can provide you withstanding of accurate service."

- machinedemon

- Posts: 19

- Joined: Tue Jan 12, 2010 12:01 pm

- Location: Houston, TX

Yes, you are right but my section of Clear Lake is still Houston (Some farther north from I-45 are Pasadena and the south side (Frendswood) is Galveston county. I am going to be traveling for work so I postponed the 220 project until late February. You guys are very helpful and gave me a lot of good tips about how to get it done cheaper. Thanks!Falcon67 wrote:Harold_V wrote:...He's in Clear Lake, down by the LBJ Space Center so I'm not sure what local codes apply - they may just use Houston's code. There is a LOT of "Houston" population that is not in the real live city limits.

JR

- machinedemon

- Posts: 19

- Joined: Tue Jan 12, 2010 12:01 pm

- Location: Houston, TX

220 Project Underway!

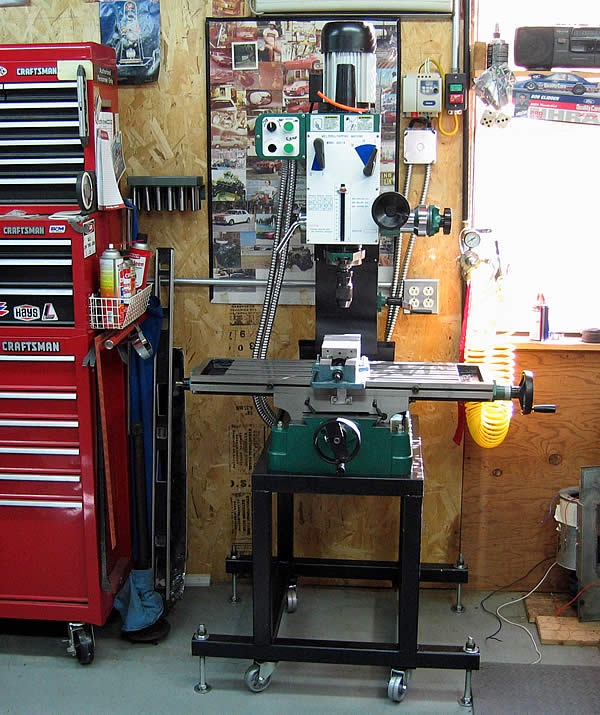

OK guys, I bit the bullet and getting my 220 connection. Now which bench mill should I buy? My main constrain is space, especially I will not like the mill to portrude more than 26 in max from the back wall. Also will like to place it in a sturdy bench I already built. I think I should stay below 600 lb, a lot less if possible.

As I said in a previous post, I build small parts (max 6x6x6) but many times use steel. Price matters but don't constrain your recommendations because of that. I appreciate your help and guidance!

Thanks

As I said in a previous post, I build small parts (max 6x6x6) but many times use steel. Price matters but don't constrain your recommendations because of that. I appreciate your help and guidance!

Thanks

- Bolsterman

- Posts: 102

- Joined: Thu Nov 12, 2009 12:36 pm

- Location: Mexifornia

Re: 220 Project Underway!

Congrats on 220! You have lots of options now, and you are officially out of my league, I'll leave 220v suggestions to others. Regarding the X3, if you are still following my thread, you'll see that the replacement X3 they sent is in good shape, and could be used without tramming at all (although I will still do it as I'm a perfectionist). Looks like my first X3 was a "Friday Afternoon Machine" after all.machinedemon wrote:OK guys, I bit the bullet and getting my 220 connection. Now which bench mill should I buy? My main constrain is space, especially I will not like the mill to portrude more than 26 in max from the back wall. Also will like to place it in a sturdy bench I already built. I think I should stay below 600 lb, a lot less if possible.

As I said in a previous post, I build small parts (max 6x6x6) but many times use steel. Price matters but don't constrain your recommendations because of that. I appreciate your help and guidance!

Thanks

Now that you mention it, there is a Griz machine that I've looked at longingly, and rejected due to its being 220 3-phase. G0519, looks like a Rong-Fu 45 clone maybe? An X3 on steroids? Might want to give it a glance. I have to give Griz customer service a double thumbs up.

Seems that the RF-45 and its clones are generally well regarded as the best of the benchtop category...if you are intent on a benchtop, that is. Sieg is also coming out with an X4, which is in the RF-45, 600 lb category. If money were no option I'd prefer the RF due to its country of origin, Taiwan. At least I think they are still Taiwanese. I remember reading somewhere that some of the Taiwanese machines are now being made in China?

A Bona Fide Soggy Bottom Boy

I found that one or two nice walnut bowls turned in the lathe are always likely to get the wife to "overlook" certain impediments to my usual activities....seal killer wrote: Make something for your wife. --Bill

'Course, it helps too that there are walnut trees growing all over this place. Sometimes we even burn it as firewood.....

Sick, isn't it?

CB&Q

Re: 220 Project Underway!

Eh? Why rejected? I have one, 3 phase an easy fix. Makes the mill work even better IMHO.Bolsterman wrote: Now that you mention it, there is a Griz machine that I've looked at longingly, and rejected due to its being 220 3-phase. G0519, looks like a Rong-Fu 45 clone maybe? An X3 on steroids? Might want to give it a glance. I have to give Griz customer service a double thumbs up.

Good news. I would be careful to not buy too light a machine. They can and do flex and a little bigger than what you think may be just about right. Mine is about 800 lbs and fits close to the space envelope you specify. I've made some small parts on it and put some big parts on it and it works great. My drill press is felling a little neglected. It's not a mill on the scale of a G0316 but the G0519 so far is a good pic for what I do.OK guys, I bit the bullet and getting my 220 connection. Now which bench mill should I buy? My main constrain is space, especially I will not like the mill to portrude more than 26 in max from the back wall. Also will like to place it in a sturdy bench I already built. I think I should stay below 600 lb, a lot less if possible.

As I said in a previous post, I build small parts (max 6x6x6) but many times use steel. Price matters but don't constrain your recommendations because of that. I appreciate your help and guidance!

Chris -

http://raceabilene.com/kelly/hotrod

"Check all parts for proper condition before operation; if normal safety precautions are noticed carefully, this machine can provide you withstanding of accurate service."

http://raceabilene.com/kelly/hotrod

"Check all parts for proper condition before operation; if normal safety precautions are noticed carefully, this machine can provide you withstanding of accurate service."

-

deltaenterprizes

- Posts: 42

- Joined: Sat Jan 06, 2007 5:16 pm

- Location: longvew,tx

Home Metal Shop of Houston

Being a newbie I would check out the Home Metal Shop of Houston club.

- machinedemon

- Posts: 19

- Joined: Tue Jan 12, 2010 12:01 pm

- Location: Houston, TX

Re: Home Metal Shop of Houston

Thank you! I did not know about this club, just checked their webpage and definitively going to join.deltaenterprizes wrote:Being a newbie I would check out the Home Metal Shop of Houston club.

MD

PS: I finally bought a Wabeco F1210hs. Please don't flame me for the muchos $ I spent! I liked the quality and size.

- machinedemon

- Posts: 19

- Joined: Tue Jan 12, 2010 12:01 pm

- Location: Houston, TX

Update

My 220 is installed but I do not have my Wabeco machine yet. I bough a X2 mill to use in a future as auxiliary mill. Joined the Houston Club and I even presented in the "show and tell" my first mill project! (a lathe stop).

Thank you all for your tips and advise.

Thank you all for your tips and advise.

Second the motion on the HMSC. Fine bunch of guys, much talent of all kinds and new members are very welcome. It's about 225 miles for me to get to a meeting these days, but I've just rejoined and would like to make a meeting now and then.

There is generally a presentation, show and tell, special interest group seminars and general shop BS. $15 for a year is one heck of a deal.

Mark

There is generally a presentation, show and tell, special interest group seminars and general shop BS. $15 for a year is one heck of a deal.

Mark