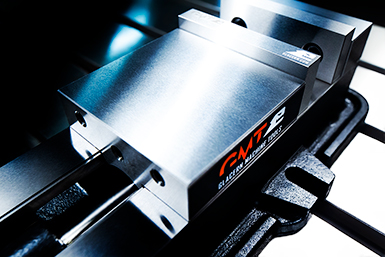

After 2 years of no luck and making due, I decided enough is enough. I have been reasonably impressed with the Shars' stuff I've bought so far and their vise looked a little more finished in the pictures than most of the other clones. They actually publish specs -- basically the same +/- 0.0005" tolerances I've seen for the D40 -- and they offer a lifetime warranty. So I bit the bullet and it arrived the other day.

It came with an inspection record, showing the claimed dimensions:

Tolerance Actual

Bed height 2.25" +/- 0.0005" +0.0002"

Parallelism bed to base 0.0005" 0.0002"

Perpendicularity fixed jaw to bed 0.0005" 0.0003"

Parallelism fixed jaw to keyway +/- 0.0005" +0.0001"

As near as I could tell, those are accurate, but we're really pushing the limit of what I have the capability of measuring. My metric Mitutoyu DTI is graduated in .01mm increments (almost 0.0004").

The 1/2" keys don't fit my 12mm table slots, but that's not really Shars' fault and it was short work to make some custom keys 1/2" on one side and 12mm on the other. After 2 years, I have mastered the skill of making a rectangle.

The real disappointment was the dang movable jaw lifted ever so slightly on the final clamp. Not much, but enough to loosen the parallel under a 123 block clamped centre of the jaws. About 0.0002" to the best of my ability to measure. A light tap with a hammer when half-tightened would deal with it. But it shouldn't be lifting, dammit!

So I took it apart. And this is what I found:

Why would anyone use a hardened insert on one side, and PAINT on the other???

So I cleaned off the layer of paint and then polished the surface with a diamond hone just to be thorough:

I gave it a smear of way oil and reassembled everything. Holding my breath, I tried again. The parallel stayed snug! It could be pulled out, but took a tight grip on the oily metal. For fun, I measured the required force:

A close eye on the DTI shows it actually lifts slightly (about half a tick -- 0.0002") as it starts to clamp then drops down ever so slightly tighter than 0 when clamped tight. Just the width of the needle; I think that's less than 0.0001":

Now I'm happy with it.