Torque values for ER Collets, Retention Knobs, Milling Chucks, etc

http://www.techniksusa.com/metal/torque_chart.htm

ER collet nut torque specs

Moderator: Harold_V

ER collet nut torque specs

Glenn

Operating machines is perfectly safe......until you forget how dangerous it really is!

Operating machines is perfectly safe......until you forget how dangerous it really is!

- coal miner

- Posts: 479

- Joined: Tue Mar 18, 2008 6:19 pm

- Location: Southern Illinios

Re: ER collet nut torque specs

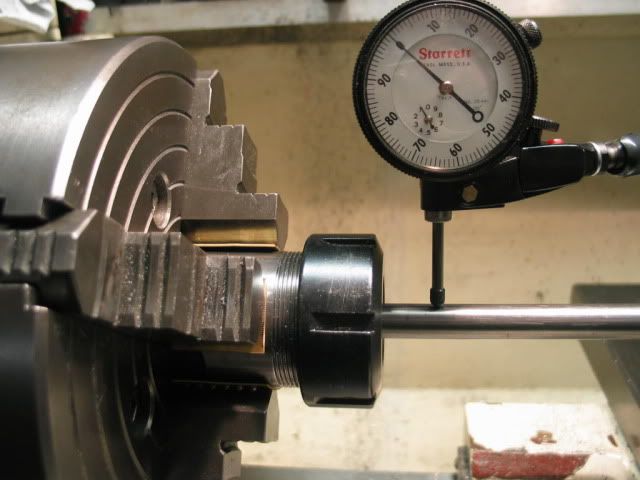

Been using the modified ( pass thru ) ER-40 adapter on the lathe for a while . I knew that they took over 100# torque and have not had a problem yet . Not very scientific , but , three raps w/ the 16 oz. Stanley orange deadblow and the piece seems to be well seated in the collect . No collects messed up , yet . Sure not recomending this procedure . When the piece gets loose in the collect , bad things happen ! A torque wrench adapter would insure that the specs were met . Thanks Glen .

The more I learn , The more I don't know !

Re: ER collet nut torque specs

Holding a part or stock with a ER style chuck would not require nearly the amount of torque as a nice polished shank carbide end mill. The part or stock will most likely be considerably softer and will grip much easier at less torque.

The chart I linked to is primarily showing the torque requirement for cutters in ER type tool holders.

The chart I linked to is primarily showing the torque requirement for cutters in ER type tool holders.

Glenn

Operating machines is perfectly safe......until you forget how dangerous it really is!

Operating machines is perfectly safe......until you forget how dangerous it really is!

- coal miner

- Posts: 479

- Joined: Tue Mar 18, 2008 6:19 pm

- Location: Southern Illinios

Re: ER collet nut torque specs

Point well taken . When I have the ER-40 w/ R-8 adapter in the mill 2 wrenches are used , one on the flats of the adapter and the other on the nut . Lots of torque applied . Don't have a torque wrench adapter , but I make sure the nut is very tight . The ER series seem to grip much tighter to the larger end mills than the regular R-8 .Glenn Wegman wrote:Holding a part or stock with a ER style chuck would not require nearly the amount of torque as a nice polished shank carbide end mill. The part or stock will most likely be considerably softer and will grip much easier at less torque.

On the adapter for the lathe the flats are covered by the chuck , hence the triple whack . The ER-40 beats a 5C hands down as for as gripping ability and also they can be used successfully if the part is sized some smaller ( around .040" IIRC ) .

The more I learn , The more I don't know !