Bill Shields wrote:Huh?

Maybe you are missing the concept of MODALITY.

I fully understand the concept.

As I said, the code is produced by the software and certainly I could remove the redundancy if I needed to save space. But it would take me more time to go through and remove it than it would add to the run-time

and this was only a "lesson." I just wanted to see if I could do it.

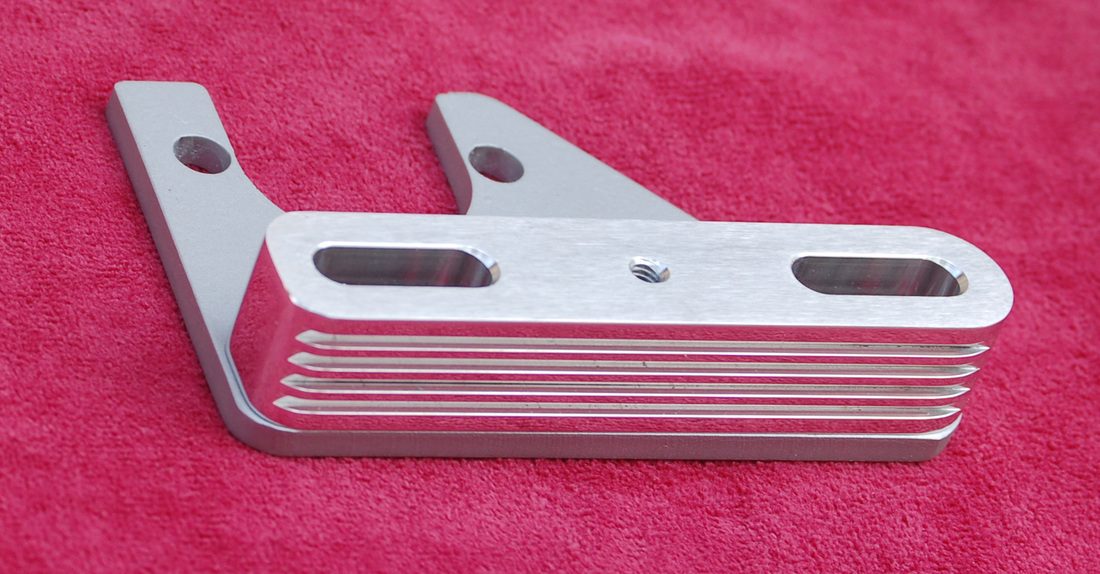

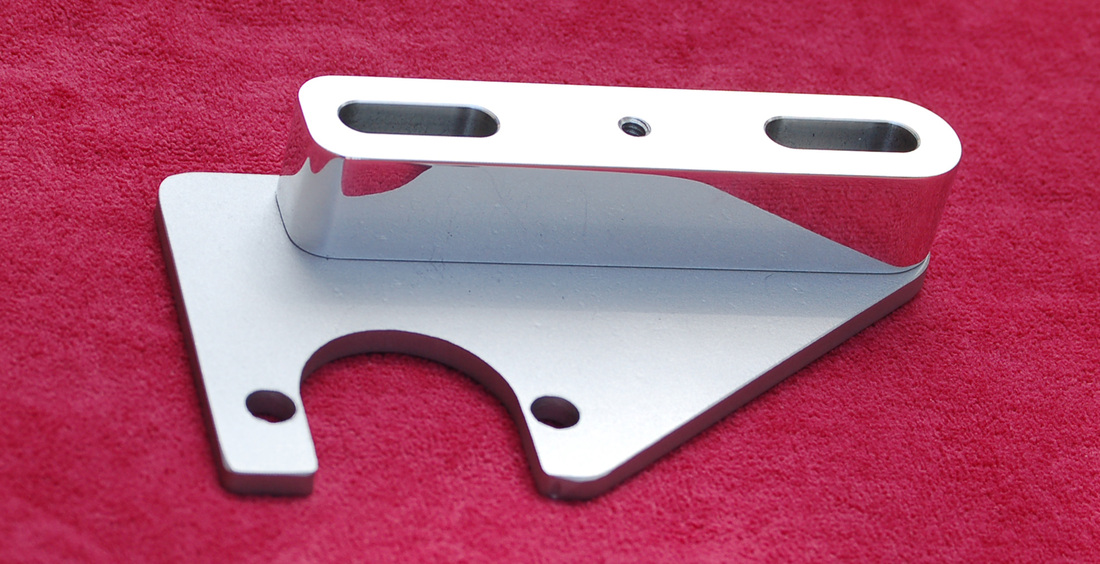

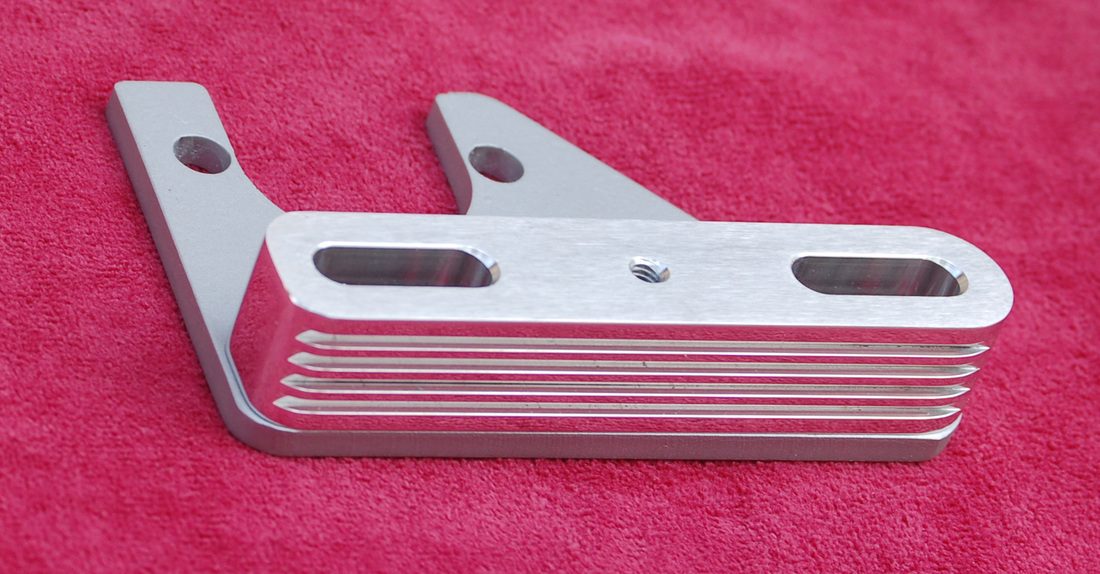

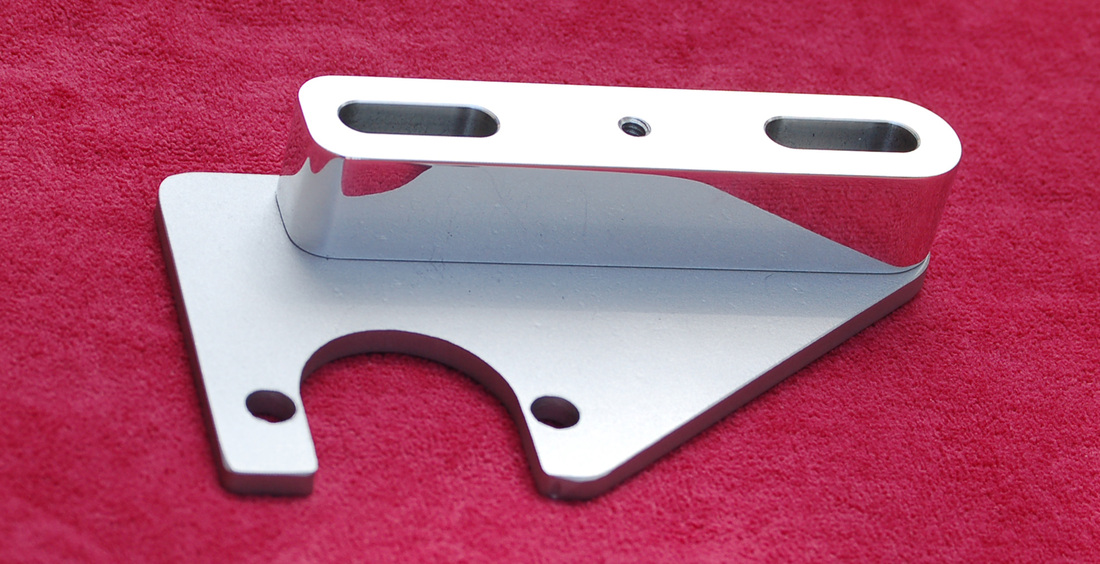

The guy makes them much faster on the Fadal because he uses aluminum with a faster feed rate and bigger cuts. I specified steel for the simulation, but can always modify the feed rates. Besides, at $12-15 each for parts and labor, I couldn't compete with that.

BTW, if someone thinks that they can undercut that price, I'm all ears!

BTW, if I'm cutting wood and my machine has a maximum speed of 2,500 RPM, is that the speed I should be using?